Aluminium mirror sheet plate

In the ever-evolving landscape of materials utilized in design and engineering, the aluminum mirror sheet plate emerges as a compelling player. Far beyond mere aesthetics, these exceptional metallic sheets evolve with advancements in technology and creative expression, serving numerous industries from architecture to electronics.

What Sets Aluminum Mirror Sheet Plates Apart?

To understand the significance of aluminum mirror sheet plates, we'll focus on their processes and properties that create distinct advantages:

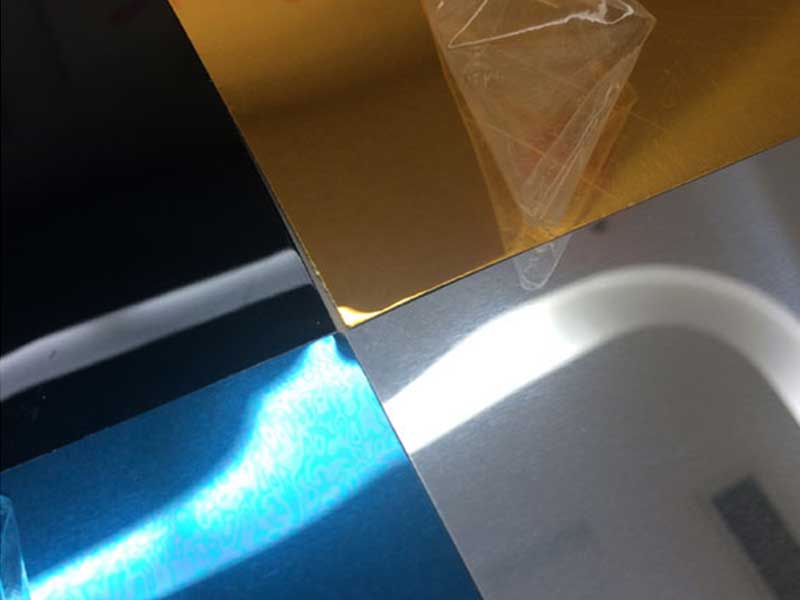

Working with mirror aluminum sheet is a fascinating blend of precision manufacturing and artistry. We're not just producing a metal sheet; we're crafting a reflective surface with incredibly tight tolerances. The process itself is demanding – from the initial alloying and rolling to the crucial chemical polishing and protective coating application. A tiny imperfection, a microscopic scratch, can ruin the entire sheet's reflectivity, making the quality control aspect incredibly critical and personally rewarding when we achieve a flawless finish. I've seen firsthand how variations in the anodizing process, even minor ones in temperature or bath concentration, drastically affect the final product's brilliance and durability. This constant pursuit of perfection, coupled with the inherent beauty of the finished product, keeps the work engaging.

Beyond the technical aspects, what strikes me is the sheer versatility of mirror aluminum sheet. It's not just for decorative purposes; it finds applications in high-tech industries like optical instruments, solar energy, and even aerospace. Seeing our product integrated into complex systems, contributing to advancements in other fields, is a profound source of satisfaction. It’s a tangible reminder that the meticulous work we do here at the factory has real-world impact, extending far beyond the factory floor. the specific needs of each client—whether it's a high-reflectivity requirement for a telescope or resistance to corrosion for outdoor signage—allows me to appreciate the intricate engineering and artistry involved in every single sheet.

-

High Reflectivity: Created through polished surface techniques or a layer of reflective coatings, aluminum mirror sheets boast reflectivity rates of up to 95%. This transcendental capability plays a crucial role across a myriad of scenarios, from decorative purposes in cosmetic displays to essential uses like light diffusion in solar panels.

-

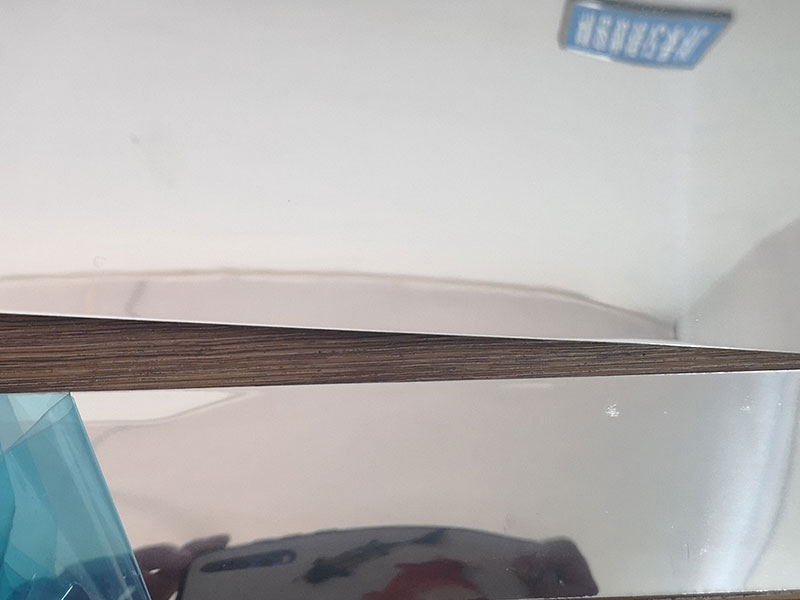

Lightweight Composition: Unlike traditional glass mirrors, aluminum sheets are lightweight, fostering easier handling and installation. The balance between strength and weight allows architects and designers to push boundaries without compromising structural integrity or safety.

-

Corrosion Resistance: Designed predominantly from aluminum, these materials possess natural oxidation resistance. Aluminum mirror sheets are particularly suited for environments exposed to varied weather conditions, making them ideal for both indoor uses in humid environments and outdoor architectural elements.

-

Customizability: Their qualities can manifest in purely practical uses where custom dimensions revolutionize architectural design. Size, thickness, and finishes can be tailored to specifications, offering flexibility that is often not feasible with conventional materials.

-

Sustainability: Aluminum is highly recyclable and does not lose its essential properties when reprocessed. With a growing emphasis on sustainability in manufacturing and construction, aluminum mirror sheets represent an eco-friendly choice that fosters circular economies.

Innovative Applications Across Industries

Given these exemplary characteristics, aluminum mirror sheet plates find enduring utility across several domains:

-

Architecture & Interior Design: Celebrated for their aesthetic appeal, these sheets are prevalent in interior design applications, ranging from backsplash installations in kitchens to reflective ceilings. By enhancing natural light flows and reducing reliance on artificial illumination, designers achieve both beauty and energy efficiency.

-

Signage and Displays: Driven by the urge for captivating visual merchandising, industries turn to aluminum mirror sheets for display cases, signage, and decorative elements. The holographic allure they offer is unparalleled, captivating consumer attention and enhancing their experiential interaction with the product.

-

Solar Technologies: Reflectance is synonymous with efficiency in solar energy production. Here, aluminum mirror sheets become integral components for parabolic solar collectors by concentrating sunlight and increasing energy yield for renewable systems.

-

Electronics: Industries harness mirror sheets in various electronic casings to improve heat dissipation and reflect light output for devices, consequently enhancing usability. In applications such as reflectors for flashlights, cameras, or LED lighting systems, they marry function and aesthetics seamlessly.

-

Transportation: Innovations within automotive and transport-related applications are notable examples. From interior lighting solutions reflecting off aluminum surfaces to functional elements such as rear-view and side mirrors, aluminum mirror plates assist tremendously in achieving both vision and safety criteria.

https://www.aluminumplate.net/a/aluminium-mirror-sheet-plate.html