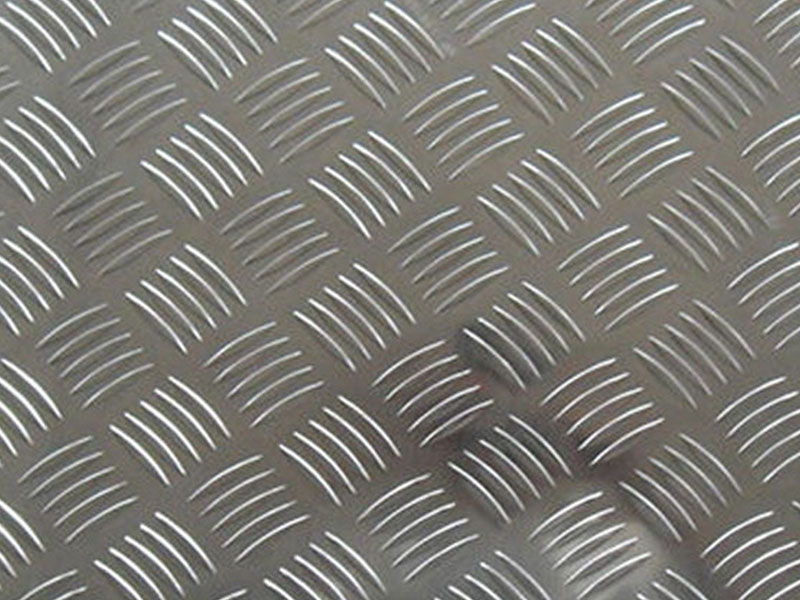

Embossed aluminum sheet 1100 3003 5052 5754 5083 6061

Embossed aluminum sheets have gained significant traction across diverse industries, valued for their durability, lightweight nature, and aesthetic appeal.

Functions of Embossed Aluminum Sheets

Embossed aluminum sheets are characterized by raised patterns or designs on the aluminum's surface. These patterns provide:

- Improved Aesthetics: They often feature decorative designs enhancing their visual appeal for use in various environments.

- Improved Slip Resistance: The textured surface reduces the risk of slipping, making them ideal for flooring in commercial and residential buildings.

- Durability: Resistant to corrosion, wear, and scratches, embossed aluminum sheets maintain their integrity in a variety of conditions.

Applications of Embossed Aluminum Sheets

The applications of embossed aluminum sheets vary significantly but are predominantly found in industries such as:

- Construction: For wall cladding, roof coverings, and siding due to their aesthetic and thermal properties.

- Automotive: Used for body panels and interior components, benefiting from weight reduction without sacrificing strength.

- Appliances: Fabricated in kitchen appliances for both function and design.

- Packaging: In food and pharmaceutical packaging, providing protection and increased shelf appeal.

- Marine: Employed in structures requiring robust resistance to sea water corrosion.

Technical Details of Embossed Aluminum Sheets

Parameters

The selection of an aluminum alloy depends on the specific requirements of each application. Below is a summarized table detailing the composite specifications, tempering conditions, and chemical properties of the mentioned alloys.

Chemical Composition

| Alloy | Aluminium (%) | Copper (%) | Iron (%) | Manganese (%) | Magnesium (%) | Silicon (%) | Zinc (%) | Titanium (%) |

|---|---|---|---|---|---|---|---|---|

| 1100 | 99.0 | 0.05 | 0.2 | - | - | 0.5 | 0.1 | - |

| 3003 | 97.9 | 0.12 | 0.7 | 1.0 | - | 0.6 | 0.1 | - |

| 5052 | 97.25 | 0.1 | 0.4 | 0.15 | 2.5 | 0.3 | 0.1 | 0.15 |

| 5754 | 94.5 | 0.1 | 0.4 | 0.5 | 3.0 | 0.4 | 0.1 | 0.1 |

| 5083 | 90.7 | 0.1 | 0.4 | 0.4 | 4.0 | 0.4 | 0.25 | 0.15 |

| 6061 | 95.9 | 0.15 | 0.7 | 0.1 | 1.0 | 0.6 | 0.15 | 0.15 |

Technical Specifications

| Alloy | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Density (g/cm³) | Thickness Range (mm) |

|---|---|---|---|---|---|

| 1100 | 125 | 210 | 24.0 | 2.71 | 0.5 - 6.0 |

| 3003 | 140 | 205 | 22.0 | 2.73 | 0.5 - 6.0 |

| 5052 | 240 | 320 | 12.0 | 2.68 | 0.5 - 6.0 |

| 5754 | 240 | 310 | 12.0 | 2.68 | 1.0 - 6.0 |

| 5083 | 260 | 350 | 12.0 | 2.66 | 1.0 - 6.0 |

| 6061 | 290 | 320 | 17.0 | 2.70 | 1.0 - 6.0 |

Alloy Tempering Conditions

For optimal mechanical properties, various tempering strands exist for each alloy group:

- 1100: H12, H14

- 3003: H14, H16

- 5052: H32, H34

- 5754: H32, H34

- 5083: H111, H112

- 6061: T6, T661

Alloy temper conditioning focuses on yield strength and ductility. Using Standard Handling Guide approved metallurgical principles ensures enhanced outcome alignment.

- Lightweight yet sturdy, with specific arduous properties embellished with surface wielder.

- Embossed elements appropriate for most mechanical processes relative to dimensional stability.

- Epoxy-resin frosted editions make them preferred in highly-corrosive environments.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-1100-3003-5052-5754-5083-6061.html