| Application | Extremely long run without baking for uv ink printing |

| Thickness | 0.15mm,0.20mm,0.25mm,0.30mm,0.40mm |

| Max width | 1350mm |

| Spectral sensitivity | 830nm |

| Exposure energy | 110~130mj/Cm2 |

| Resolution | 1~99% at 200lpi |

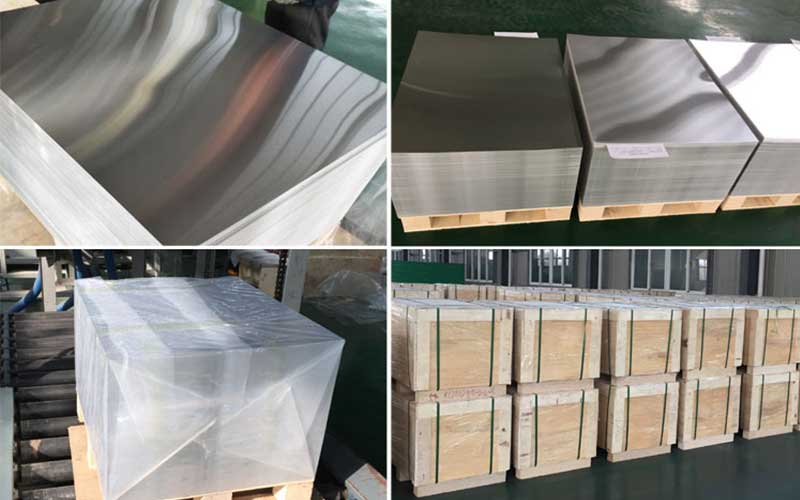

| Specification | 0.15mm 100PCS/box;0.25mm 50PCS/box;0.30mm50PCS/box; 0.40mm 30 PCX/box; customized |

| HS code | 37013024 |

| Transport Package | Export Standard Seaworthy Package |

Double-layer thermal CTP plates are advanced printing plates characterized by a dual-layer coating designed to enhance performance and quality. Both layers work in synergy to provide superior image reproduction and increased durability, setting a new standard in thermal CTP technology.

Composition and Structure

A double-layer thermal CTP plate typically consists of the following components:

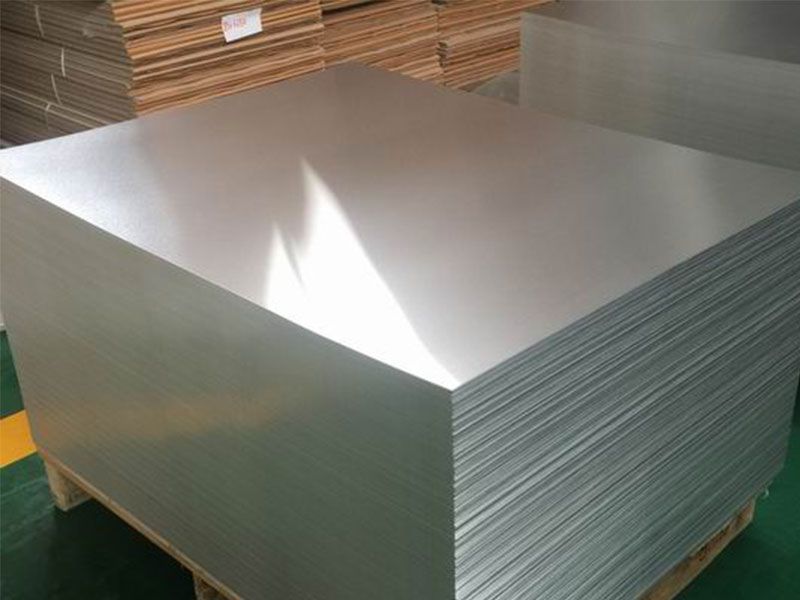

Aluminum Base: The foundation of the plate, providing the necessary rigidity and stability for precise printing. Aluminum is widely used due to its excellent properties such as lightweight, resistance to corrosion, and durability.

First (Sensitive) Layer: This layer is designed to capture and store the image section of the design when exposed to a thermal laser. It provides excellent resolution capabilities, allowing for extremely fine detail and high-quality image reproduction.

Second (Protective) Layer: This top layer helps protect the sensitive layer and enhances the plate’s performance. It aids in improving the plate’s overall durability, ensuring it can withstand more extended press runs without degradation or loss of quality.

How Double-Layer Thermal CTP Plates Work

The operation of double-layer thermal CTP plates involves several precise steps:

Laser Exposure: Using a thermal laser, the plates are exposed according to the digital image file. The energy from the laser precisely targets the sensitive layer, altering its chemical structure to reveal the design.

Development: Post-exposure, the plate undergoes a development process which removes the non-image areas, fully revealing the image intended for printing.

Printing Process: Once prepared, the plate is mounted onto a printing press. Due to its robust structure and precise imaging, it facilitates optimal ink transfer, ensuring high-quality prints.

Post-press Advantage: The dual-layer design enhances reusability and minimizes wear, allowing for consistent print quality across extended print runs.

Benefits of Double-Layer Thermal CTP Plates

Enhanced Durability: The protective layer guards against scratches and abrasions, allowing these plates to perform under high-pressure conditions and extending their lifespan.

Superior Image Quality: The sensitive layer is engineered for high resolution, delivering exceptional detail and clarity in printed images.

Cost Efficiency: Despite their advanced technology, these plates can be more cost-effective over long runs due to reduced waste and decreased need for frequent replacements.

Environmental Benefits: Many double-layer thermal CTP plates are designed to be processless or require fewer chemicals in the development stage, contributing to reduced environmental impact.

Applications

Commercial Printing: Ideal for high-volume jobs such as catalogs, brochures, and promotional materials due to superior longevity and image precision.

Packaging: The durability and quality make these plates perfect for packaging solutions that require consistent high-quality output.

High-End Publishing: Books and art reproductions benefit from the fine detail and accuracy they provide.