0.5mm 1.0mm thick Color Anodized Aluminium Plate

The Unsung Hero: 0.5mm and 1.0mm Thick Color Anodized Aluminum Plates

In the ever-evolving landscape of materials science, the value of innovations like color anodized aluminum plates cannot be overstated. Among these, the 0.5mm and 1.0mm thick variants emerge as unsung heroes, delivering a blend of beauty, functionality, and formidable strength in a remarkably lightweight package.

Working with 0.5mm and 1.0mm thick color anodized aluminum plates presents a fascinating dichotomy. The 0.5mm sheets, while lighter and easier to handle, require significantly more care during processing. Their thinness makes them prone to scratching, warping, and even tearing during stamping, bending, or even simple handling. We often see higher rejection rates with this thickness, particularly when dealing with complex geometries or demanding finishing processes. The vibrant colors achievable through anodizing are truly stunning on this thinner gauge, making it ideal for applications where aesthetics are paramount, like decorative panels or high-end consumer electronics. However, this beauty comes at the price of increased fragility, demanding extra attention throughout the production chain.

Conversely, the 1.0mm thickness offers a much more robust and forgiving material. It's less susceptible to damage during manufacturing, leading to lower waste and improved yields. This increased resilience translates to greater design freedom; more complex shapes can be achieved with less risk of failure. However, the added weight and stiffness can present challenges of its own. It requires more powerful equipment for processing, and certain finishing techniques might need adjustment to avoid cracking the thicker anodize layer. The thicker plate is usually preferred for more industrial applications where durability and strength are prioritized, like exterior cladding or signage, though the color anodizing still lends itself to a visually appealing finished product.

the Process: What Makes Anodized Aluminum Unique?

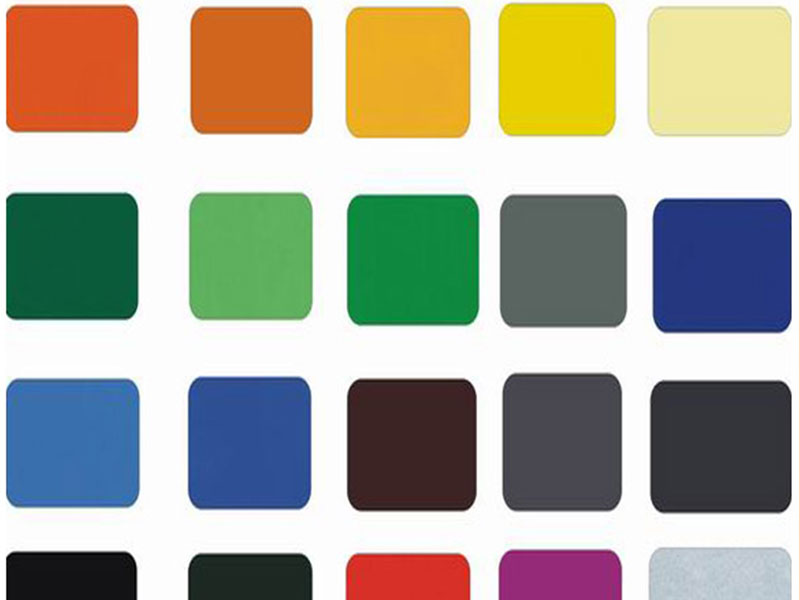

Anodizing is an electrochemical process applied to aluminum to escalate its durability, corrosion resistance, and aesthetic appeal. This technique creates a protective oxide layer on the surface of the aluminum, effectively fortifying the material and allowing for a broad selection of color finishes thanks to various dyeing techniques.

The resulting anodized aluminum plates not only is know visually but also boast an fidelity to long-term use. This is a game-changer in industries requiring aesthetic appeal without compromising structural integrity.

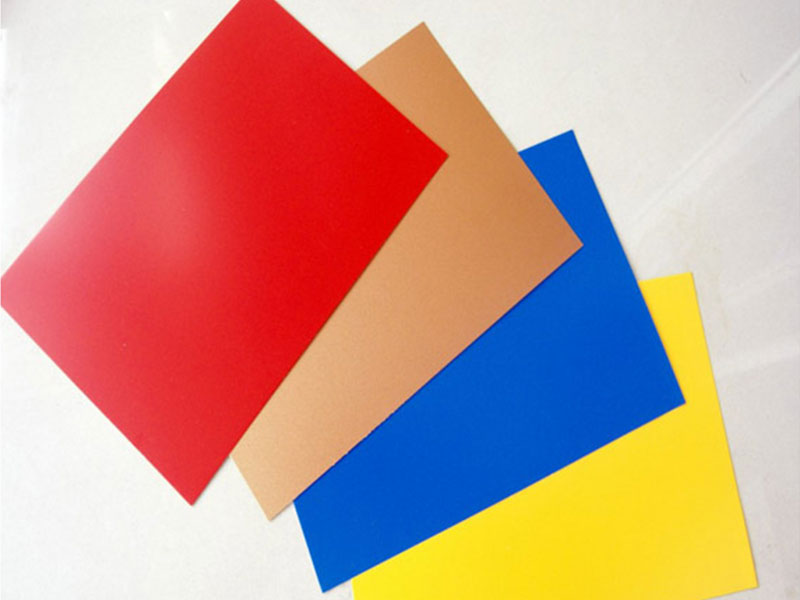

Thickness Matters: The Choices – 0.5mm vs. 1.0mm

While purchasing anodized aluminum, the thickness becomes a pivotal selection criterion based on the demands of the intended application. The nuanced differences between the 0.5mm and 1.0mm plates open doors to various uses.

-

Lightweight but Strong (0.5mm Aluminum Plate): The 0.5mm thickness strikes an ideal balance for applications such as signage, packaging solutions, and temporary structures requiring elegance coupled with lightweight versatility. This thickness provides sufficient strength while remaining easy to transport and install. Its lower weight trait is advantageous for industries that focus on efficiency, such as transportation and other sectors that prioritize material weight for fuel consumption and logistics, all while ensuring that beautiful, colorful designs catch the eye.

-

Enhanced Durability (1.0mm Aluminum Plate): On the other hand, the 1.0mm thick plate offers additional robustness that some applications demand. Its sturdiness makes it a popular choice for architectural facades, industrial enclosures, and applications involving higher wear and tear like outdoor fixtures or equipment housings. With enhanced thickness, users do not need to compromise on durability, making it safer against mechanical stress and damage.

Versatility at Its Best: Industries Adopting Color Anodized Plates

Architectural Applications: In architecture, color anodized aluminum plates elevate both aesthetic and functional components such as cladding, facades, and interior surfaces. The colors and finishes are plentiful, which seamlessly harmonize with various design themes using sleek + modernistic vibes.

Automobiles: The automotive industry leans toward these color anodized plates for interior designs, lining, or as part of custom bodywork. The durability against the elements prolongs the lifespan of car aesthetics, making it easier for upgrades and customizability while standing up to harsh exposure.

Electrical Appliances: Micro-thin anodized aluminum fits well in appliance HAVC fans and other electrical internal components. These components benefit from a rust-free outer layer while providing appealing colored alternatives appealing to consumers.

Why Invest in Quality?

While the initial investment in higher-grade coated aluminum, whether 0.5mm or 1.0mm, is crucially worth it, bespoke solutions tailored for frequent and diverse applications are invaluable. By thoughtfully selecting quality anodized aluminum sheets, businesses enable longevity and serviceability that translates into cost savings over time.

Final Thoughts

Color anodized aluminum plates stand as a fusion of engineering marvel and creative potential. The differing thicknesses, specifically 0.5mm and 1.0mm, offer traits and strengths indispensable in various sectors. This carefully reviewed material endowed with a visually striking appearance ensures its indefinite relevance in an aggressively competitive construction and design landscape. Investing in high-performing aluminum plates presents an appealing prospect that blends art and innovation, cementing their status in premium applications far beyond ordinary materials.

Opt for 0.5mm or 1.0mm thick anodized plates today to redefine the quality and appearance of your next project.

https://www.aluminumplate.net/a/05mm-10mm-thick-color-anodized-aluminium-plate.html