Coated Finish Color Painted Aluminum Sheet

Aluminum, a universally recognized lightweight metal, has garnered significant attention for its outstanding adaptability in numerous applications. However, when this versatile metal is paired with a coated finish and color painting, it transcends conventional capabilities, introducing exciting opportunities into design and production realms.

The Aesthetic Edge: Features of Coated Finish Color Painted Aluminum Sheet

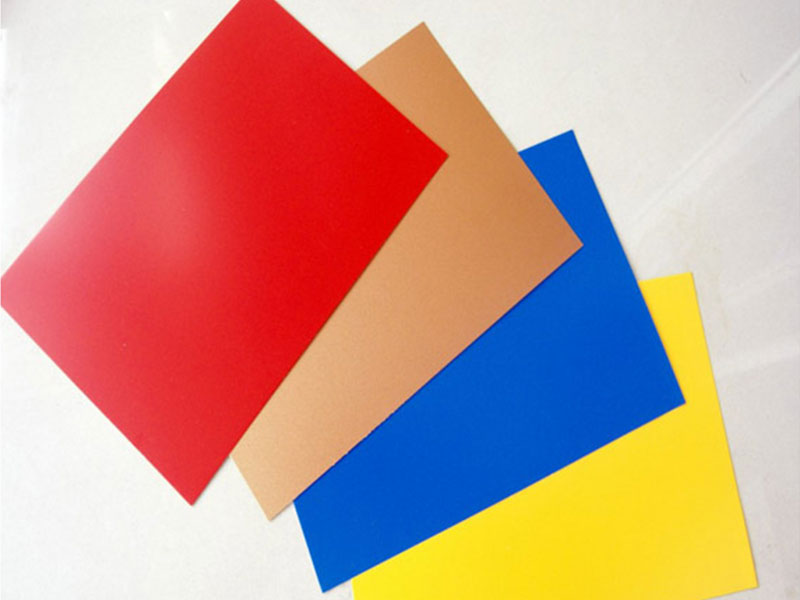

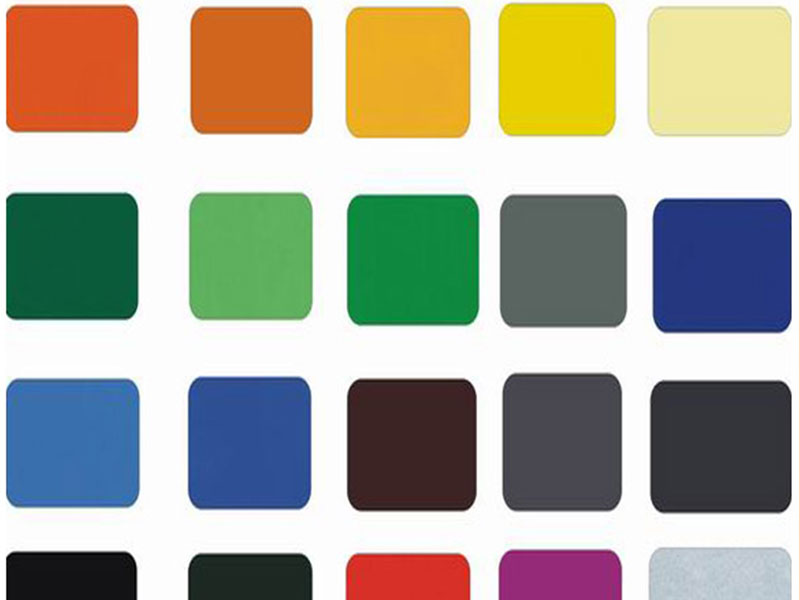

At its core, a coated finish color painted aluminum sheet delivers both practical and aesthetic benefits. One standout feature is its extensive range of colors and finishes. Whether you envision a sleek matte black for a modernist architectural boundary or a radiant finish that catches the eye, the options are virtually limitless. This adaptability provides designers and manufacturers with the creative freedom needed to align products impeccably with branding aznd consumer preferences.

One of the most critical aspects of producing high-quality coated aluminum sheet with a painted finish is achieving consistent color across large production runs. Slight variations in the aluminum substrate, coating application pressure, or even ambient temperature and humidity can lead to noticeable color discrepancies. We’ve had instances where seemingly minor adjustments to the curing oven temperature profile resulted in a subtle but unacceptable shift in hue, necessitating a costly rework of a significant batch. the interplay of these factors and implementing rigorous quality control measures, including spectrophotometric analysis at various stages, is paramount to maintaining customer satisfaction. Furthermore, the durability of the paint itself is a constant area of focus; we've learned that even small changes to the paint formulation can drastically impact the sheet's resistance to scratching, chipping, and UV degradation, especially in outdoor applications.

Beyond the technical challenges, anticipating and meeting specific customer color requirements presents its own set of unique hurdles. Matching a pantone reference, for example, requires precision and often involves iterative adjustments to the paint recipe. Customer expectations regarding gloss level, texture, and even the subtle variations allowed within a “color family” are incredibly diverse. We've seen projects requiring custom color matching that stretched our capabilities, forcing us to explore new techniques and partner with specialized paint suppliers. Effective communication with the client throughout the color matching process, including providing samples and clear tolerances, is essential to avoid costly revisions and ultimately achieve a product that perfectly aligns with their vision.

Moreover, the coated finish offers excellent protection against environmental factors. This innovation creates a barrier that resists oxidation, rust, and corrosion, typically encountered in both indoor and outdoor settings. The result? A longer lifespan for products, preserving not only radical hues but structural integrity even under harsh climatic conditions.

Another captivating feature is the sheet's ability to encompass diverse coating techniques, such as electrostatic spray, powder coating, or even liquid paint. Each method provides distinct benefits, ensuring a suitable finish for virtually any context, from large-scale industrial applications to intricate, delicate components used in technology or consumer goods.

The Practical Applications: An Integral Component Across Industries

The versatility of coated finish color painted aluminum sheets underscores their application across multiple sectors. In construction and architecture, these sheets embody both form and functionality; they serve as visually striking facade panels, providing sustainability through energy efficiency due to reflective properties that minimize solar heat gain while enhancing a building's exterior appeal.

The automotive industry showcases another increasing trend where coated color aluminum sheets are paramount in manufacturing. Beyond reducing vehicle weight—which leads to improved fuel efficiency—these sheets integrate seamlessly into design features such as trims, dash panels, and major body structures. This dual role in aesthetics and functionality endorses the drive toward environmentally-friendly driving options.

Additionally, the commercial furniture sector recognizes the impact of beautifully designed aluminum products. From modern office desks to stylish and resilient outdoor furniture, the coated sheets allow architects and designers to create striking pieces that withstand wear while offering stunning visual appeal for consumers.

Further still, the technology and electronics sector finds an essential need for the lightweight and durable characteristics of painted aluminum sheets. Electronic devices require precision and high durability, often found in the rollers, casings, and frameworks—which benefit significantly from this kind of material treatment. Coupled with aesthetics, gadgets and devices also become eye-catching, appealing more to trend-savvy consumers.

https://www.aluminumplate.net/a/coated-finish-color-painted-aluminum-sheet.html