Uv ctp aluminum plate

In an era defined by rapid technological advancements, it's easy to overlook the role that materials play in the broader progression of industries—especially in print technology. Among these unsung heroes, UV Computer-to-Plate (CTP) aluminum plates shine as essential players, granting remarkable benefits that enhance efficiency, accuracy, and sustainability.

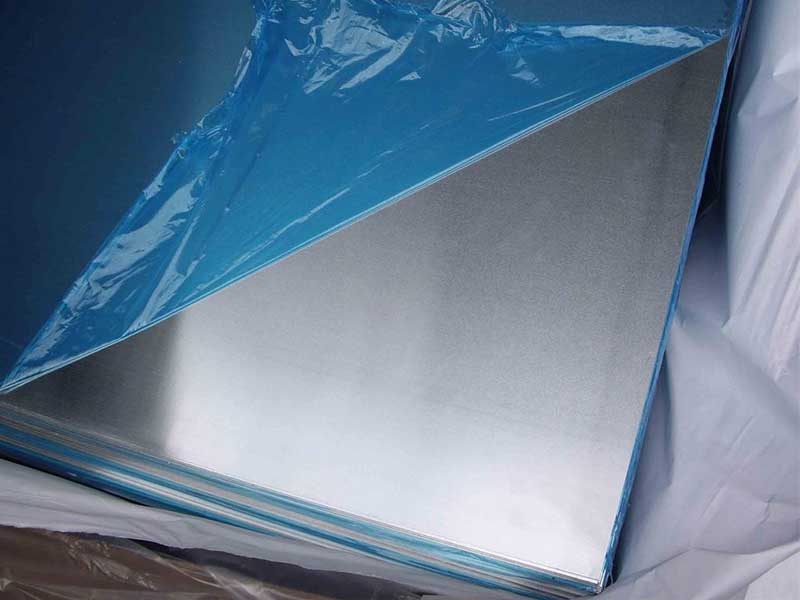

The Intricate Make-up of UV CTP Aluminum Plates

At its core, a UV CTP aluminum plate consists of several vital components, tailored to meet the demanding standards of contemporary printing processes. The seamless fusion of high-purity aluminum substrate with a specialized photopolymer coating determines the exceptional features of these plates.

From my perspective working with UV CTP aluminum plates, the biggest challenge isn't the chemistry itself – although maintaining consistent coating quality and minimizing defects like pinholes remains crucial – but rather the interplay between the plate's performance and the printing press. Slight variations in the UV curing unit's intensity, the ink viscosity, or even the ambient temperature can significantly affect the print quality. We're constantly fine-tuning parameters and collaborating with press operators to optimize the entire workflow, ensuring sharp images, consistent dot gain, and minimal plate wear. A seemingly minor adjustment on one end of the process can drastically alter the outcome at the other, making troubleshooting demanding but rewarding when we achieve a perfect print.

Personally, I find the constant evolution of these plates fascinating. The drive for higher resolution, faster processing speeds, and longer plate lifespan necessitates ongoing innovation in both the plate coating and the imaging technologies. We're seeing a shift towards more environmentally friendly processing chemicals, a trend I fully support. Witnessing the advancement from traditional thermal CTP plates to the current generation of UV-curable plates has been remarkable, and I'm eager to see what future developments bring – perhaps even plates that require even less energy consumption or completely eliminate the need for traditional processing chemicals.

-

Aluminum Substrate: The fundamental asset here is aluminum itself. Light-weight yet incredibly robust, aluminum provides an excellent flatness that ensures high-quality image reproduction. It can withstand the vigorous demands of the printing press while maintaining its structural integrity.

-

Photopolymer Emulsion: Coated upon the aluminum is a layer of photopolymer emulsion designed specifically for UV (ultraviolet) exposure lying at the heart of this technology. This emulsion undergoes extensive chemical changes once exposed to UV light, allowing highly precise to materialize revealing intricate details in artworks and texts.

-

Surface Treatment: In pursuit of maximizing image clarity and print capacity, UV CTP aluminum plates often undergo surface treatments that enhance their adherent properties and anti-abrasion characteristics enabling longevity and durability during extensive operational cycles.

Defined Features Worth Noting

The innovative design of UV CTP aluminum plates économiques tendencies can be encapsulated into several compelling features:

-

Superior Image Resolution: One of the distinguishing attributes of these plates is their potential to deliver ultra-high-quality images with exact fidelity to the original design--sometimes exceeding 350 lpi which translates to impeccable details and crisp lines.

-

Higher Registration Accuracy: The strength of the aluminum base plays a facilitating role in ensuring excellent registration compared to traditional printing methods—vital for achieving seamless multi-color prints that demand strict alignment.

-

Environmentally Sustainable Production: Unlike conventional methods requiring solutions for gumming and acid treatment, UV CTP technology eliminates environmental concerns surrounding hazardous dependence giving way to eco-friendly alternatives featuring negligible waste.

-

Swift Preparation Rate: As the immediacy of today's lifestyle dictates pressing needs on print cycles, manufacturers benefiting from UV CTP have reported significant scalability thus offering speedy make-ready times that drastically cut project turnaround times.

Diverse and Dynamic Applications

The applications for UV CTP aluminum plates are as diverse as the printing challenges they address. Herein lies an overview of some preferred industries tapping into their remarkable properties:

-

Commercial Printing: Strong performance in high volume productions like magazines, catalogs, and packaging derivatives exhibits profitability assets conducive for commercial printers seeking flexibility and execution precision.

-

Label and Decal Printing: Enterprises producing stickers and labels take enhancement measures leveraging registration precision and meticulous detailing affixed to UV CTP aluminum plates as their tools of choice delivering consistent outputs.

-

Decorative Printwork: Decorative applications often demand specific richness in visuals—from textiles to signage—that are National face-printed vying at skilled pressing strategies realizing gratification due to photo-lattice perfection residing in aforementioned plates.

-

Security Printing: Applications demanding high fidelity, such as document certifications and security tags, benefit from the predictable and extremely methodological reproduction processes offered by UV CTP technology conveying authenticity and Monográp financial trust.

-

Medium to Small Batch Workflows: Smaller polishing-precision-centered industries taking evolving techniques have progressively adapted UV CTP options allowing detailed print designs way beyond typical batch runs delivering custom printing solutions.