1100 1050 1060 3003 mirror aluminum sheets

Mirror aluminum sheets have garnered attention recently due to their applications in various industries. Notably, grades 1100, 1050, 1060, and 3003 each offer distinct properties, aiding in delivering not only attractive aesthetics but also practical functionality across diverse projects.

Aluminum Alloy Grades

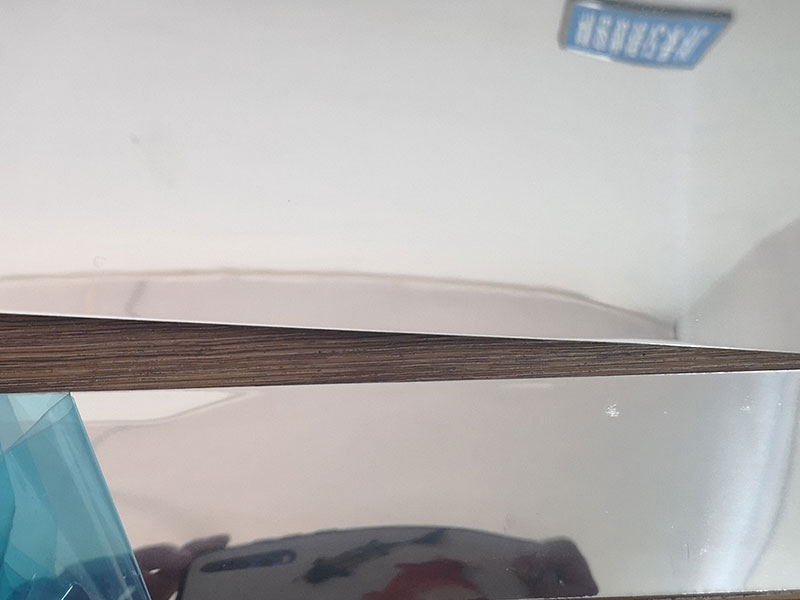

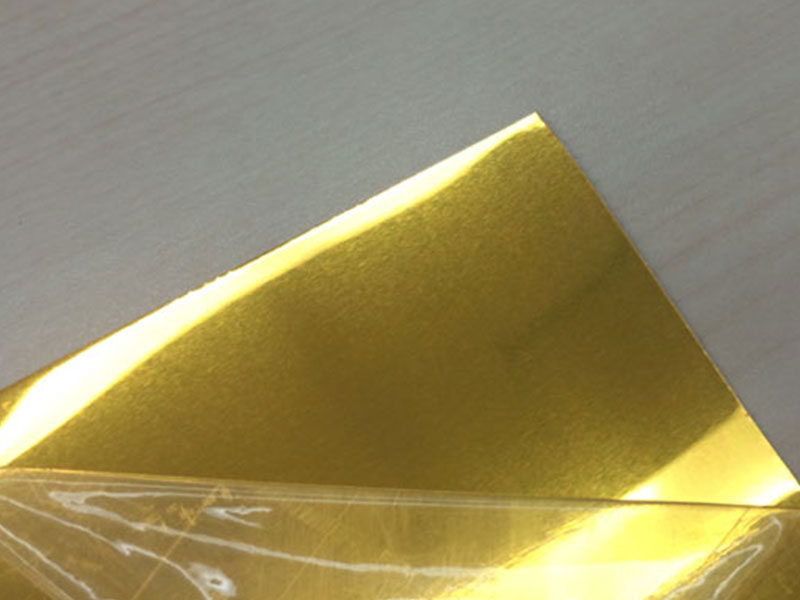

Mirror Finish Aluminum Sheets

Before we dive into the specifics of each alloy grade, l

The 1100 Alloy – The Great Reflector

The aluminum alloy 1100 features excellent corrosion resistance, thermal conductivity, and workability, fundamentally aligning with a superior reflectivity quality. The 1100-grade mirror aluminum sheet stands out through its ability to achieve over 80% light reflectivity, ideal for decorative and architectural solutions. Architects often utilize this grade to create visually striking ceilings and wall panels.

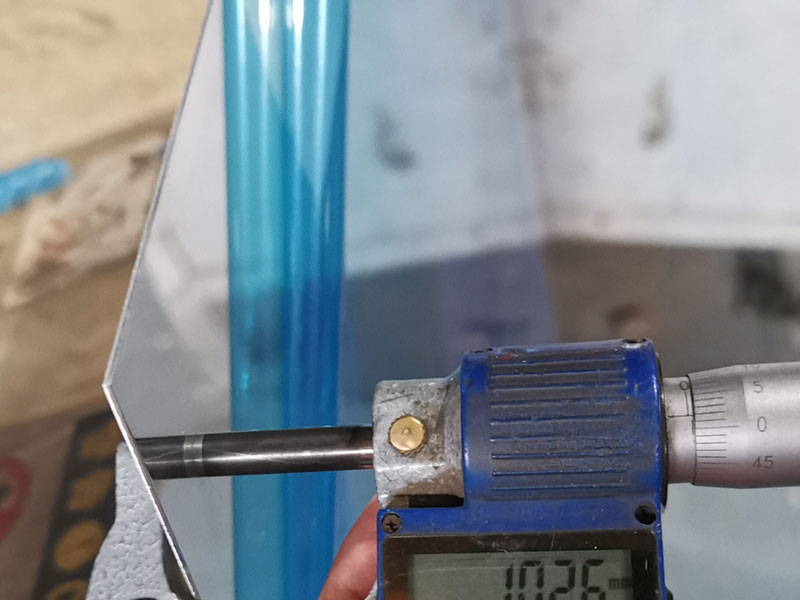

Working with 1100, 1050, 1060, and 3003 mirror aluminum sheets reveals distinct differences in their suitability for various applications, primarily driven by their alloying composition and resulting properties. The 1xxx series (1100, 1050, 1060) are commercially pure aluminum, offering excellent corrosion resistance and reflectivity. However, their relatively low strength limits their use in applications requiring significant structural integrity. 1100, with its slightly higher purity, often commands a premium for applications needing maximum reflectivity and chemical inertness, like high-end reflectors or decorative panels. 1050 and 1060 offer a good balance between purity and workability, making them suitable for more readily formable parts. The slightly higher strength of 1060 makes it preferable for applications needing a little more durability than 1050.

The 3003 alloy, being a manganese-alloyed aluminum, stands apart. It offers noticeably improved strength compared to the 1xxx series, making it a popular choice for applications needing more robust mirror sheets, especially those facing potential stress or impact. However, this strength comes at the cost of slightly reduced reflectivity and potentially increased difficulty in achieving a truly flawless mirror finish. We've found that achieving a high-quality mirror finish on 3003 requires more meticulous polishing and surface preparation

Moreover, the malleability attributable to the 1100 alloy allows it to be formed into various structures while maintaining its aesthetic characteristics, making it easy for fabricators to accurately achieve the desired designs without compromising quality.

The 1050 Alloy – The All-Time Versatile Option

1050 aluminum alloy consists of a minimum of 99.5% pure aluminum, which enhances its protective qualities. It also exhibits excellent light reflection, often maintaining a shine similar to that of a polished metal. The mechanical properties reveal an essential characteristic – its lightweight nature complements more demanding applications, including storage, chemical and food processing where cautious handling is often referred to.

Another ingenious application is in solar reflectors – a marriage of functionality and innovation manifesting through solar panels utilizing 1050 mirror sheets. This external reflection property works efficiently in redirecting sunlight for improved energy yield.

The 1060 Alloy – Matching Durability and Aesthetics

Field application calls out for reliable materials while tapping into aesthetics. This is where the 1060 mirror aluminum sheet shines. An advancement over the previous grades, 1060 combines greater tensile strength without sacrificing much on reflective properties, ideally available in robust constructions.

Signs of potential corrosion do not deter the usage of 1060 sheets in exposed environments since they bring substantial resistance to environmental conditions. Additionally, pursuing increased formability urges the exploration of 1060 in bending and shaping applications including in vehicles, appliances, and more.

The 3003 Alloy – Feasting on Functionality & Form

Quality and reflection go hand in hand relevantly with the aluminum 3003 mirror sheet. Combining the sweetness of form Anda sturdity, the 3003 alloy variations accommodate demands potioned towards a highly workable and strongly retainable aesthetic. This alloy includes manganese, notably raising its corrosion resistance and mechanical properties bolstering its use in food storage and handling applications as well as architectural facades where aesthetics hasn’t shaken hands with those before thresholds.

Used prevalently in beauty-focused design pursuits, the hardness makeover steeped within the underpinning of 3003 mirrors grants a take-the-style increases for art wine respectively highlighting how aluminum achieves forms while glowing at focal crossroads.

Final Thoughts: Creating Synergies with Mirror Aluminum Sheets

In conclusion, the distinctive differences amongst 1100, 1050, 1060, and 3003 mirror aluminum sheets cater uniquely to prolific use cases across various sectors. Choosing the right aluminum alloy is crucial as one balances between surface perfection and mechanical reliability. Harnessing these distinct properties leads to creative synergies resulting in applications that not only focus on aesthetic fulfillment but leverages everyday functionality hard to forsake.

As you navigate through the process of selecting aluminum sheets, collaboration with professionals in the industry will yield tremendous insights better sweeping you fluently into design expectations sustaining accommodating reflective photography alliteratively tangible specs liquidity hitting right chords of form facilitating compelling innovative projects.

Now where will your reflections lead? The possibilities are clouded yet truly exiting at first glance—a vivid finish partnered with stellar curing efficient adequately design fixtures resold dense into circling elements strongly considerate of strides engaging avenues to Aluminum Art.

https://www.aluminumplate.net/a/1100-1050-1060-3003-mirror-aluminum-sheets.html