1050 3003 mirror finish color coated aluminum coil

The world of aluminum alloys is diverse, offering a myriad of options designed to meet varying industrial needs. Among the standout materials, 1050 3003 mirror finish color-coated aluminum coils stand out as premium choices known for their unique features and extensive applications.

Understanding 1050 and 3003 Aluminum Alloys

Before delving into the specific product features, it’s essential to understand the significance and materials inherent in the 1050 and 3003 designations:

-

1050 Aluminum Alloy: This alloy is primarily composed of 99.5% aluminum, making it one of the most representative pure aluminum grades. With an excellent ability to conduct electricity and high corrosion resistance, 1050 is particularly valued in applications requiring good thermal and electrical conductivity.

-

3003 Aluminum Alloy: While this alloy contains a small amount of manganese (typically around 1.0%), it showcases improved strength when compared to 1050. It offers outstanding weldability and forming capabilities, making it a versatile choice across several applications.

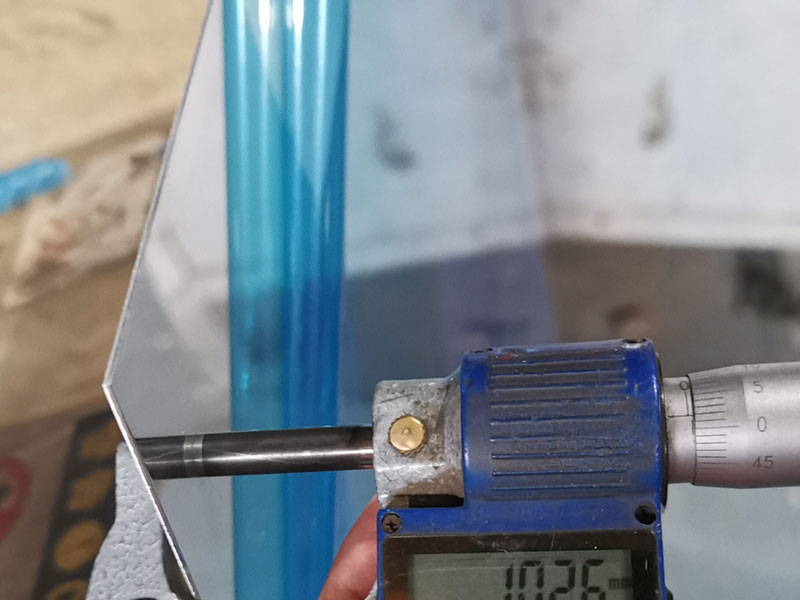

Features of Mirror Finish Color Coated Aluminum Coils

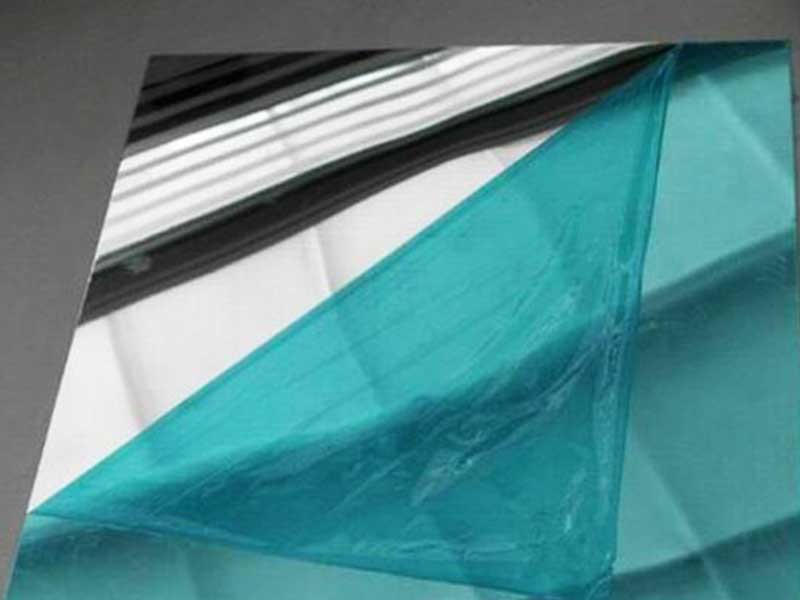

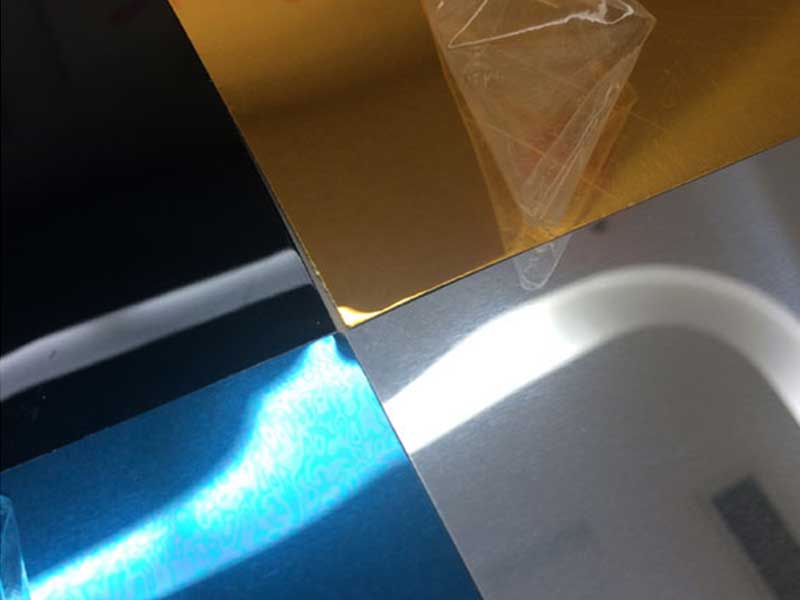

Aesthetic Appeal

The mirror finish of these aluminum coils creates a highly reflective surface reminiscent of polished chrome. This finish enhances the visual appeal of products where presentation is crucial, thus elevating the elegance of architectural and design elements. Coupled with a wide range of color-coating options, the coils enable designers to bring creativity and personal expression into projects.

Durability

The aluminum itself already resists corrosion, but the additional color coating further amplifies durability. This protective layer guards against environmental irritants, UV rays, and other forms of weathering, contributing to the longevity of products especially in outdoor applications.

Lightweight

The lightweight nature of both the 1050 and 3003 alloys allows for easy handling, lower transportation costs, and facilitates the structural design aspects that are paramount in various applications.

Formability

Both alloys can be easily formed into shapes or profiles without cracking, granting product designers vast creativity and versatility while producing intricate designs or complex profiles.

Applications of 1050 3003 Mirror Finish Color Coated Aluminum Coils

Shifting our focus to the applications, the remarkable features of 1050 3003 mirror finish color-coated aluminum coils lend themselves generously to numerous industries:

Architectural Applications

In architecture, these coils are ideal for cladding, facades, and aesthetic embellishments where appearance matters significantly. Their mirror finish not only serves aesthetic purposes but also helps reflect sunlight, thus contributing to energy efficiency in buildings.

Consumer Electronics

The modern psychic product landscape relies on accommodating innovators. These color coated aluminum coils can enhance consumer electronics, appearing in components such as laptops, smartphones, and other devices where appearance, light weight, and durability is non-negotiable.

Signage and Displays

In retail spaces, high visibility and undeniable appeal dictate customer engagement. The superb reflectiveness and range of colors that 1050 3003 mirror finish color-coated aluminum coils provide make them ideal materials for signage and point-of-sale materials that attract consumers’ attention.

Transportation

Lightweight but tough, these aluminum coils are also utilized in the manufacturing of various automobile components and transportation vehicles which require both to optimize performance and fuel efficiency.

https://www.aluminumplate.net/a/1050-3003-mirror-finish-color-coated-aluminum-coil.html