1050 1060 1070 1085 mirror polished aluminum sheet

Mirror polished aluminum sheets are synonymous with elegance and functionality in both architectural design and manufacturing industries today. Within this vast world of production, the specific grades 1050, 1060, 1070, and 1085 are prominent for their unique properties, excellent reflectivity, and diversified usability.

the Grades: 1050, 1060, 1070, and 1085

Before their functions and applications, l

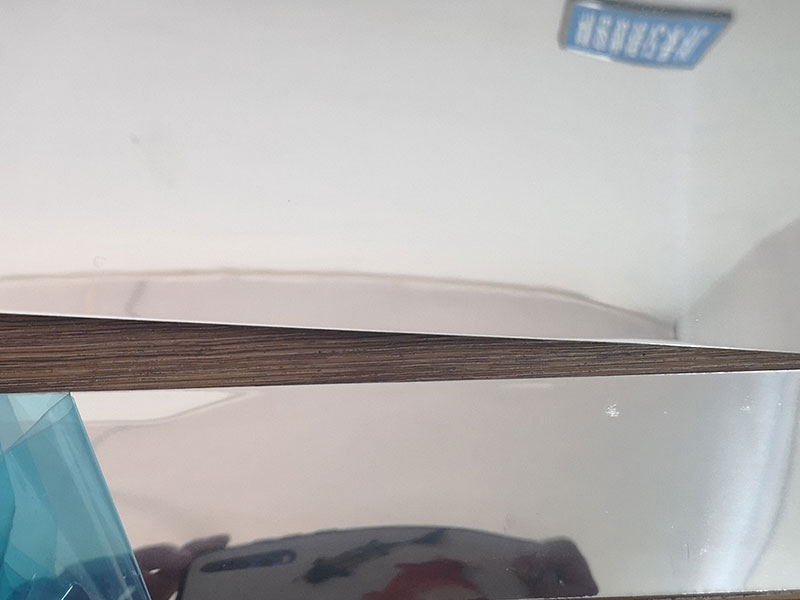

Working with 1050, 1060, 1070, and 1085 mirror polished aluminum sheets reveals distinct differences in their workability and final product characteristics, despite their similar alloy series. The 1050, being the purest, is exceptionally soft and easy to form, making it ideal for applications requiring deep drawing or complex shapes. However, its softness also makes it susceptible to scratching during the mirror polishing process, necessitating extra care and potentially higher production costs. The slightly higher strength of 1060 and 1070 alloys offers some improvement in scratch resistance, but they can still be challenging to polish to a truly flawless mirror finish. We've found that 1085, with its higher iron content, offers better scratch resistance, but it's often more difficult to achieve a consistent, high-quality mirror finish due to its increased hardness. This trade-off between formability and scratch resistance often dictates the alloy selection for a particular project.

Our experience highlights the importance of precise control during the mirror polishing process regardless of the alloy. Factors like abrasive grit selection, polishing time, and pressure significantly influence the final reflectivity and surface quality. Minor inconsistencies in any of these steps can dramatically affect the final product, leading to imperfections like swirl marks or uneven brightness. We've found that investing in high-quality polishing equipment and rigorous training for our operators is crucial

- 1050 Aluminum

- Chemical Composition: Designed with higher pure aluminum content (>99.5%), it boasts superior ductility and corrosion resistance.

- Features: Its ultimate tensile strength is moderate, and its fatigue strength is remarkably high.

- Applications: Often found in food and chemical handling industries, it is also prized for its excellent flash capability.

- 1060 Aluminum

- Chemical Composition: Has about 99.6% of aluminum, closely related to the 1050 grade; this similarity makes it an optimal choice in many environments.

- Features: Exhibits high thermal and electrical conductivity, alongside reliable formability and weldability.

- Applications: Commonly utilized in electrical applications and heat exchangers where low weight yet great thermal efficiency is critical.

- 1070 Aluminum

- Chemical Composition: Contains around 99.7% aluminum, further increasing its elemental purity compared to its neighbors.

- Features: Superior corrosion resistance, added mechanical properties due to its higher purity level, enhancing longevity.

- Applications: This aluminum grade is frequently options for artistic endeavors and decorative architectural finishes because of its brilliant reflectivity used in mirrors and show pieces.

- 1085 Aluminum

- Chemical Composition: At over 99.9% purity, it is among the highest purity shapes available, making it an elite option in its class.

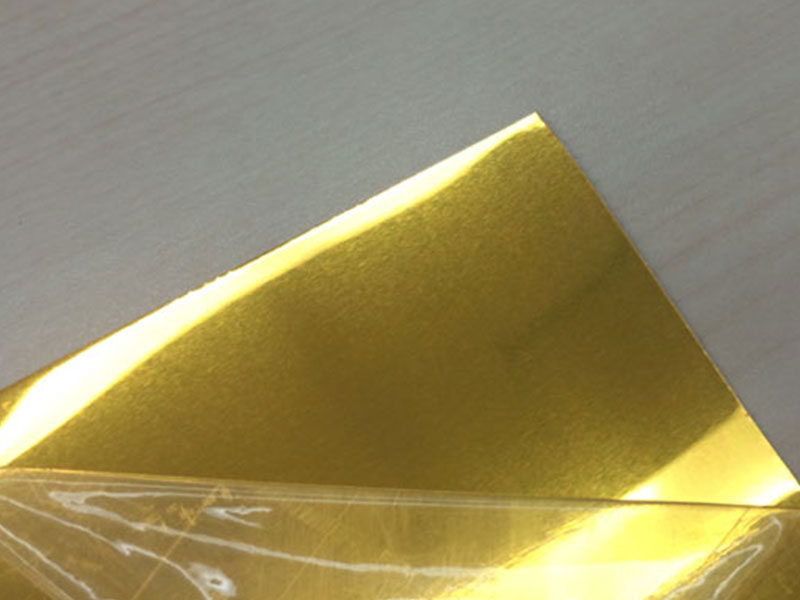

- Features: Retaining its structural integrity while achieving a reflective quality that truly takes ‘shininess’ to another level.

- Applications: Witness its innovative use in laser-cut architectural elements and electroplated components where aesthetic impact is paramount.

Functionality Meets Versatility

Each grade provides exceptional utility serving both aesthetic and functional roles:

-

Architectural Applications: Aluminum mirror sheets are vital for glamorous interior and exterior designs, creating stunning reflective facades, and reflective surfaces in building accents.

-

Lighting Industry: With their exceptional reflectance, rooms illuminated with LED strips around mirror polished aluminum create optimal ambiance, increasing overall brightness while maintaining elegance.

-

Signage and Display Solutions: Increasingly used in custom labels, retail store decorations, and even artistic displays; the dazzling surface finish players collect attention helps brands is know effortlessly.

-

Transportation and Automotive Sectors: Engineers and manufacturers take great advantage of the lightweight qualities while combining reflective finishes. Mirror polished panels enhance reflective lights for safety and hone the aerodynamic prowess aiding fuel efficiency.

-

Consumer Products: Think utensils to high-end products like silverware. Their aesthetics equip offerings with modern touches essential for influencing consumer choices.

Technical Integrations in Modern Manufacturing

Traditional and laser cutting techniques can easily handle their ductile properties with minimal waste generation. The polymorphic invitation offered by polished sheets also lends an effortless edge to printing wrap accessibility feeding into marketing industries embracing captivating visual boosts.

However, it’s notable that while the printing or coating methods have advanced remarkably, maintaining aesthetic integrity demands rigorous control over the grade selection.

https://www.aluminumplate.net/a/1050-1060-1070-1085-mirror-polished-aluminum-sheet.html