Solar reflective mirror polished alloy 3003 aluminum coil

In the quest for renewable energy and efficient light management, the role of materials remains critically important. One standout solution that has garnered attention in various industries is the solar reflective mirror polished alloy 3003 aluminum coil.

the 3003 Aluminum Alloy

In the world of aluminum alloys, the designation '3003' refers to an alloy that incorporates manganese as its primary alloying element. Comprising 97.5% aluminum, it delves into the intriguing domain of medium-strength non-heat-treatable alloys, showcasing excellent corrosion resistance and formability. These features make it a go-to for various decorative and industrial applications.

Features and Chemical Properties

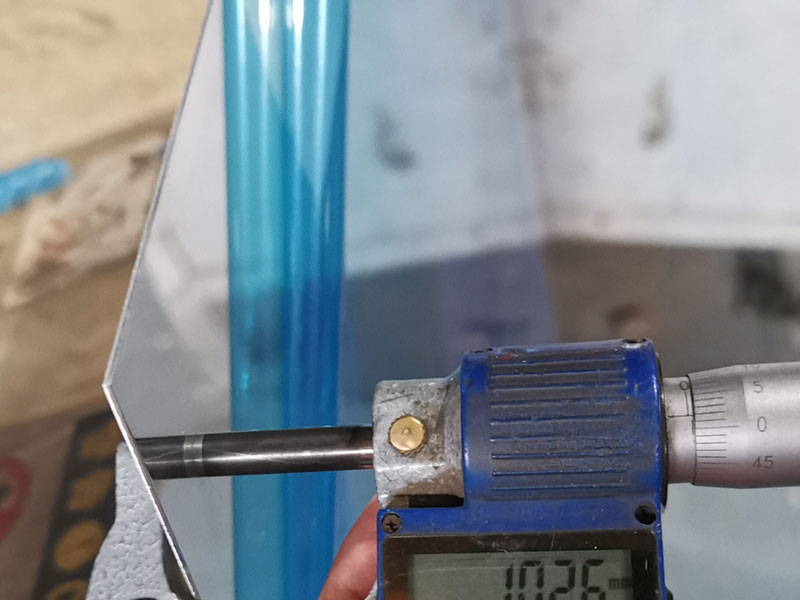

Parameters:

- Chemical Composition:

- Aluminum (Al): 97.5% Min

- Manganese (Mn): 1.0% - 1.5%

- Copper (Cu): 0.0% - 0.05%

- Iron (Fe): 0.0% - 0.7%

- Other elements combined: ≤ 0.1% each, ≤ 0.25% in total

Mechanical Properties:

- Yield Strength: ~125 MPa

- Tensile Strength: ~190 MPa

- Ductility: High, with elongation at break reaching around 20%

- Hardness: Approximately 75 BHN

Implementation Standards

For manufacturers and consumers, compliance with established standards is vital. This includes ASTM B209 and GB/T 3880, which ensure specific thicknesses, widths, and tempering for aluminum used in such applications. The alloy is sometimes compounded further, with cladding or coatings, to enhance its reflective properties - crucial for solar energy applications.

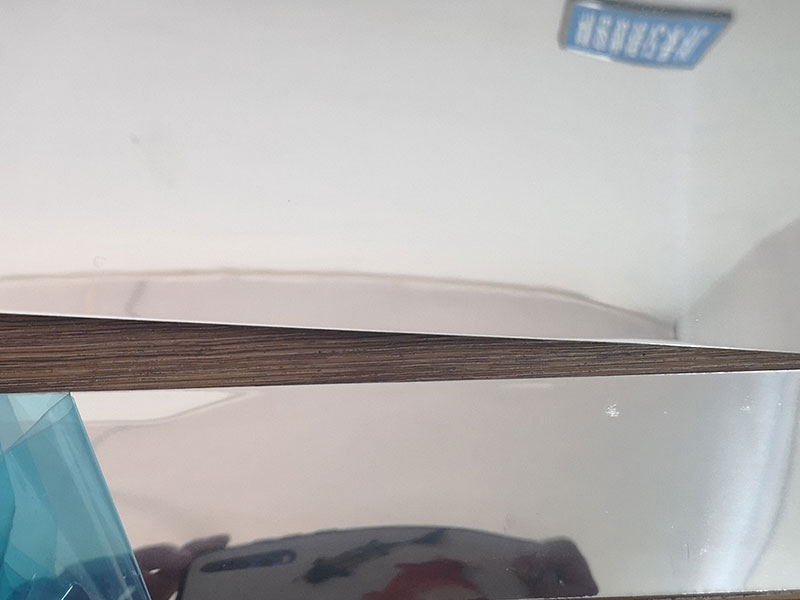

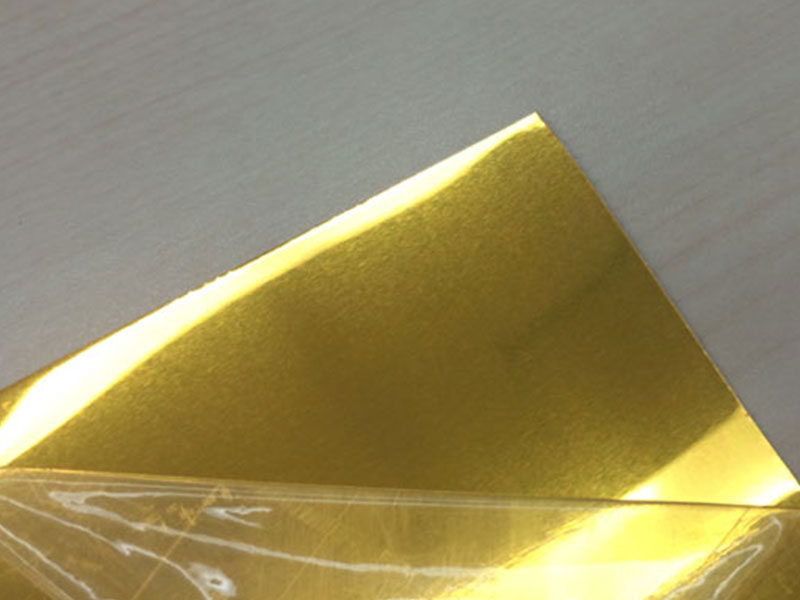

The Art of Polishing

One of the standout characteristics of the 3003 aluminum alloy is its ability to be mirror polished. This reflects not only occurring sunlight but also provides aesthetics, capturing attention in both architectural and solar endeavors. The polishing process is not just about giving the material a sleek look. It significantly increases its resilience against corrosion, enhancing its lifespan and performance, especially in varied environments.

Industrial Applications

When we consider where the solar reflective mirror polished alloy 3003 excels, several applications come to light:

Solar Reflectors: 3003 is prevalent in solar thermal systems as it reflects sunlight effectively to heat water and produce energy. Those mirror-polished surfaces maximize efficiency.

Architectural Elements: Whether it's in the creation of eye-catching facade treatments or reflective signage, the reflectivity of polished aluminum serves both functional and aesthetic roles.

Component Parts: In vehicles or appliances where weight reduction and corrosion resistance are sought, as well as available reflective surfaces, this aluminum coil shines.

Advantages of Using 3003 Aluminum Coil

The solar reflective properties of this alloy contribute to energy efficiency. In traditional architectural applications, reduced heat absorption leads to cooler indoor spaces, thus lowering air-conditioning costs. Additionally, the corrugated nature of aluminum also enables lightweight yet durable structures, offering durability alongside flexibility.

Environmental Considerations

With growing concerns regarding the environmental impact of traditional energy sources, it’s impossible to overlook the eco-friendliness of options such as the 3003 aluminum alloy. Aluminum is 100% recyclable, maintaining its material properties even after several recycling cycles. By offering a process that harnesses solar power more effectively through reflectivity, alloy 3003 doesn’t just play a role in energy; it acts as a contributor to sustainability.

https://www.aluminumplate.net/a/solar-reflective-mirror-polished-alloy-3003-aluminum-coil.html