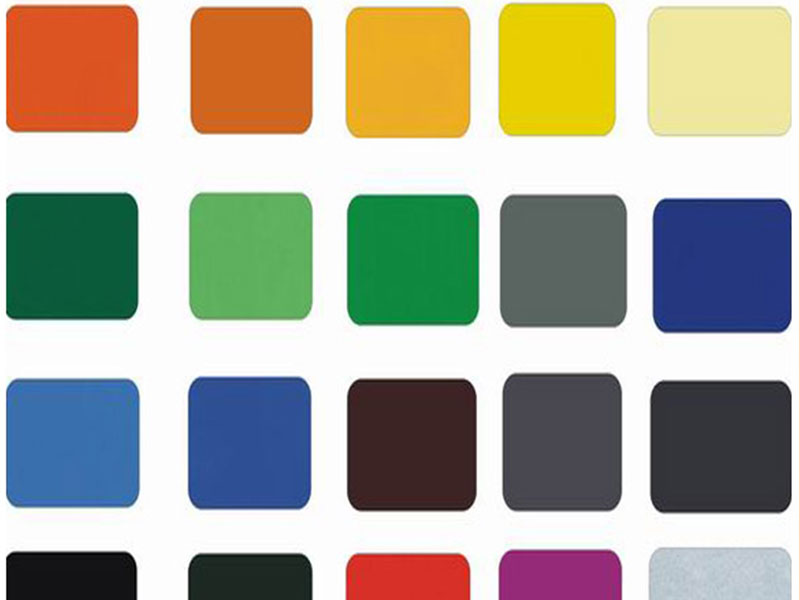

1050 1060 1100 3003 color coated aluminum plates

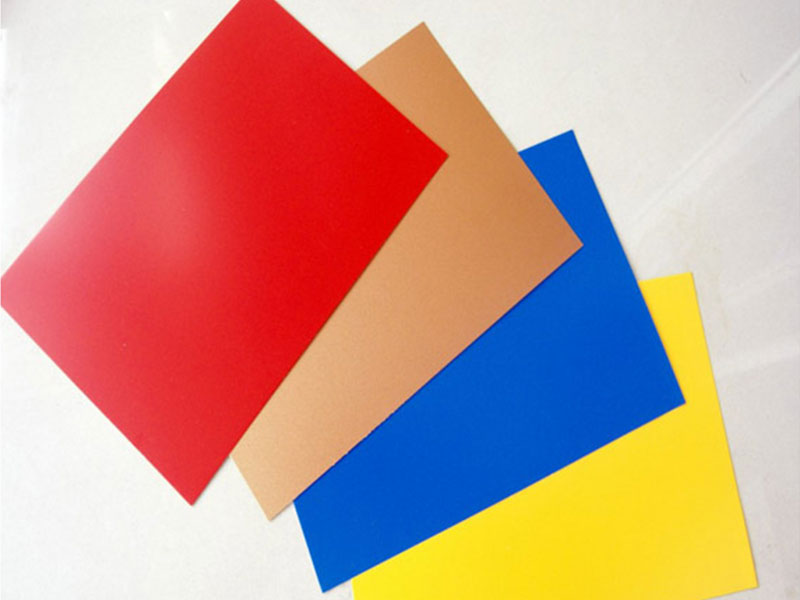

When it comes to innovation and engineering prowess, coated aluminum sheets have become indispensable in various sectors ranging from construction to automotive. Particularly, the 1050, 1060, 1100, and 3003 grades of these sheets offer a unique blend of functionality characteristics that make them ideal for both aesthetic and functional applications.

the Aluminum Grades

To appreciate the wide variety of functions that these coated aluminum sheets provide, it's essential to first understand their composition and grading:

-

1050 Aluminum Sheet: Characterized by its excellent corrosion resistance, high ductility, and conductivity, the 1050 sheet achieves distinctive results in electrical applications. With a purity of more than 99%, it is one of the softest aluminum alloys, making it easier to cold work and shape using various techniques without cracking.

-

1060 Aluminum Sheet: Similar to 1050 in its elemental makeup but with slightly higher strength, the 1060 aluminum grade is renowned for its good forming capabilities due to its metallurgical properties. Highly suited for anodization, it offers vibrant dyeing options, making it a preferred choice in the signage industry as well as architectural applications, giving options for vivid colors overlaying functionality.

-

1100 Aluminum Sheet: Known for its high thermal and electrical conductivity, the 1100 sheets boast superior working and forming characteristics. It is commonly utilized in cookware and chemical processing equipment due to its excellent corrosion resistance, allowing it effectively to serve in applications where non-reactivity is crucial.

-

3003 Aluminum Sheet: Esteemed for its balance of strength and workability, the 3003 aluminum grade features favorable machining characteristics and better resistance to corrosion compared to the 1000 series. This makes it ideal for everyday products including decorative applications, automotive parts, and cooking equipment—where durability meets utility with the freedom of design.

Unique Functions and Real-world Applications

The remarkable versatility of these grades equates to wide-ranging functionalities rooted in their compositions. Here are some applications reflecting their technical advantages:

-

Architectural Cladding and Facades: The allure of colorful building surfaces can be achieved using coated aluminum sheets particularly from the 1060 and 3003 grades. Both deliver high reflectivity, substantial yield strength, and ease of installation while echoing the desired aesthetic appeal in urban architecture. The durability and weather resistance make them optimal choices for exterior applications.

-

Transport, Temporary, and Permanent Structures: In the transit industry, the lightweight properties of 1050 and 1100 become extraordinarily essential, lowering the weight, increasing fuel efficiency, and ensuring that applications—such as bus and truck bodies—are safe without compromising easy repairs should the need arise.

-

Everyday Kitchenware and Gadgets: The corrosion assembly of 3003 and excellent manufacturing paths of 1100 designed aluminum grades drive their demand in creating pots, pans, and other kitchen accessories—their functionalities willing them towards maximum utility in culinary processes while maintaining style and finish options.

-

Electrical Applications: The high electrical conductivity of both the 1050 and 1060 grades finds prominence in various electrical wiring channels and components, sufficing structured gear within gadgets and small appliances pushing forward in energy solutions.

https://www.aluminumplate.net/a/1050-1060-1100-3003-color-coated-aluminum-plates.html