1050 1060 1100 H14 Color Coating aluminum sheet

When it comes to choosing the right material for numerous applications in modern manufacturing and design sectors, aluminum sheets—particularly the color-coated varieties—are taking the lead. Among these, the 1050, 1060, and 1100 H14 series is know not just for their aesthetic appeal but also for their inherent properties and diverse potential uses.

Exceptional Characteristics of 1050, 1060, and 1100 Aluminum

Pure Composition and Series Specification One of the intrinsic features of these alloy series lies in their nearly pure aluminum composition, with 1050 and 1060 having at least 99.5% and 99.6% aluminum, respectively. The 1100 series, while slightly alloyed with elements such as copper, keeps purity levels around 99%, culminating in excellent corrosion resistance and formability. The H14 temper designates these sheets as work-hardened and partially annealed metals, ensuring improved mechanical properties—a pivotal concern for constructional stability and performance consistency.

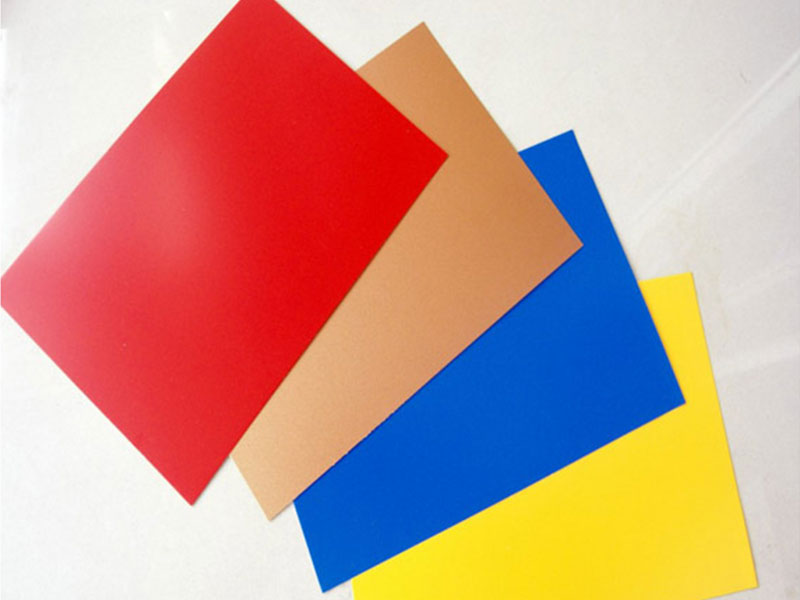

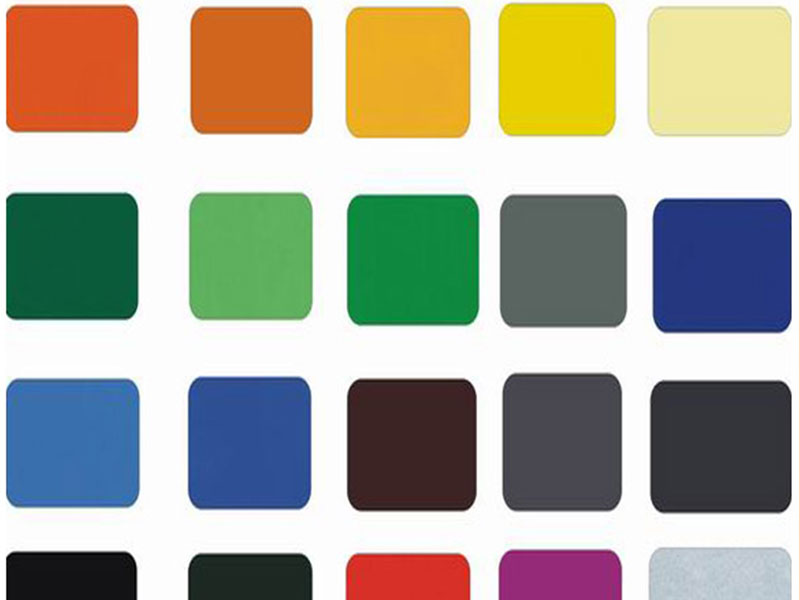

Color Coating Advantages Moisture and gradient shifts over time can lead to noticeable wear and fade in exposed materials. To combat this, the color-coating process applied to these aluminum sheets enhances not only their aesthetic features—available in diverse colors—but also contributes to sustainability. Using techniques like polyurethane-based coatings and PVDF (polyvinylidene fluoride), these sheets become UV-resistant, providing long-lasting protection against environmental decay without compromising beauty. Furthermore, the coatings ensure easy colorization options, making mass customization feasible for various businesses.

Applications in Various Industries

Architectural Design One need only take a stroll through contemporary urban design landscapes to identify the role of these aluminum sheets in facade installations, window frames, and even as interior cladding. The aesthetic selection that color-coated aluminum sheets match offers an appealing balance between durability and visual excellence, satisfying both architects and clients. Their lightweight character eases installation while minimizing the building's structural load—a critical factor in modern green building practices.

Consumer Products A less propagated use lies in consumer products such as kitchen gadgets, furniture, and more. The edge that aluminum sheets bring in terms of weight, beauty, and durability characterizes current market trends for enjoying home aesthetics. In environments that require material longevity alongside gaming in colors are valuable; subsequently, color-coated aluminum sheets cater excellently to both interior and exterior demands regarding kitchen appliances and outdoor furniture.

Electrical & Electronic Enclosures The fascination for 1060 and 1100 H14 aluminum sheets extends into electrical equipment casing and LED enclosures. Due to their non-magnetic property and the reflectivity that ensures optimal conductivity performance, these sheets are climbing to preference in the electronic manufacturing booths. This permits not only better aesthetics but ensures efficient energy management modes where these devices are located — a non-negotiable aspect in today’s high-efficiency landscape.

Transport and Automotive Sectors Although light by nature, the metallic steadfastness in both the 1050 & 1060 coupled with H14 temper backs weight-saving stability upon critical momentum at high transport standards. Rendered vital to directives on creating lighter and thus more fuel-efficient designs across information. Above all with coatings providing admirable scratch and rust prevention capabilities— make-space dedicated to finish assets heat appears outstanding, though increased efficiencies across haul feasibility ensure a competitive market close to development gold.

https://www.aluminumplate.net/a/1050-1060-1100-h14-color-coating-aluminum-sheet.html