Mirror aluminum sheet (1060 h18)

Unveiling the Brilliance of Mirror Aluminum Sheet (1060 H18): Functions, Technical Details, and Unmatched Applications

In the realm of materials, few can match the versatility and aesthetic appeal of mirror aluminum sheets, particularly the 1060 H18 grade. Known for its glossy brilliance and lightweight properties, the 1060 H18 variety has gained prominence across multiple sectors. the multifaceted capabilities and unique characteristics of this material unveils not only its visual allure but also its functional prowess in various domains.

An Insight into Mirror Aluminum Sheet (1060 H18)

The 1060 H18 mirror aluminum sheet is a specific grade of aluminum, defined by its increased purity—typically around 99.6% aluminum content. This high purity level contributes to its lightweight nature while imparting exceptional structural integrity.

Working with 1060 H18 mirror aluminum sheet presents a unique set of challenges and rewards. Its high reflectivity, stemming from the 1060 alloy's purity and the H18 temper's relatively soft yet workable nature, makes it ideal for applications requiring pristine surface finish. However, this very softness means it's susceptible to scratching and marring during handling and processing. We've found that implementing stringent cleanroom practices, utilizing specialized tooling (e.g., soft-jawed clamps and non-abrasive cleaning agents), and meticulous training of our personnel are absolutely crucial for maintaining consistent quality. Even minor imperfections can significantly impact the final reflectivity, leading to costly rejects, so preventative measures are key. Furthermore, the sheet's inherent anisotropy—meaning its properties vary depending on the rolling direction—is vital for optimal cutting and forming to avoid warping or distortion.

Our experience shows that proper storage is equally critical. Protecting the sheets from environmental contaminants like dust and humidity is paramount to preventing surface degradation and maintaining the superior reflective qualities. We've successfully implemented a system of individually wrapped sheets stored in controlled environments, significantly reducing defects and optimizing the lifespan of the material. Additionally, precise control over the anodizing process, when used, is crucial for achieving consistent color and enhancing corrosion resistance without compromising the mirror finish. Careful calibration of the anodizing bath and post-treatment processes are necessary for optimal results

Technical Specifications:

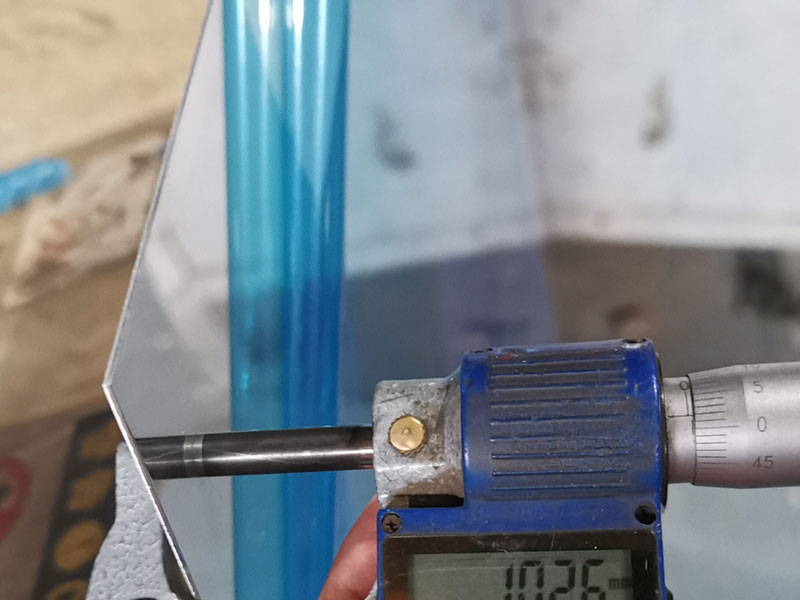

- Thickness: Available in varying thicknesses, typically from 0.2 mm to 6 mm.

- Weight: The density is approximately 2.7 g/cm³, allowing for easy manipulation and installation.

- Temper: The H18 temper indicates that the sheet has been subjected to a cold working process, making it stronger and sturdier without a loss in light weight.

- Reflectivity: Upwards of 85% reflectivity, this aluminum sheet not only enhances aesthetic appeal but improves energy efficiency, especially in lighting applications.

Multifunctional Roles and Unique Applications

One of the standout qualities of the 1060 H18 mirror aluminum sheet is its unmatched versatility. The combination of its reflective finish and lightweight durability opens a myriad of applications across industries ranging from decoration to practical architectural uses.

1. Architectural Features:

The shimmering surface of mirror aluminum sheets makes them a staple in modern architecture. They are commonly used in external building facades, ceilings, and partitions. The optical illusion created by its reflective nature not only adds visual depth to large spaces but also aids in enhancing natural light, reducing reliance on electricity.

2. Commercial Display Products:

In retail, presentation is everything. The eye-catching shine of 1060 H18 aluminum can elevate product displays, making it a popular choice for fixtures, shelves, and promotional stands. This sheet contributes to an overall branding experience, portraying luxury and modernity.

3. Automotive Industry:

In the automotive sector, functionality meets aesthetics as mirror aluminum sheets are used in decorative interior trims and accents. Due to its light weight, it is also an excellent choice for reducing vehicle weight, thereby improving fuel efficiency.

4. Kitchen and Appliance Surfaces:

In domestic appliances, stainless-steel designs often steal the show; however, mirror aluminum sheets offer a superior lightweight substitute. They’re employed in refrigerator fronts, microwave finishes, and stovetops, blending sleek modern design with enhanced functionality.

5. Signage and Logo Demarcation:

Owing to its high reflectivity and neat craftsmanship, 1060 H18 sheets are frequently utilized in signage and logos, giving a prominent appearance to brand messaging and directing customer attention.

https://www.aluminumplate.net/a/mirror-aluminum-sheet-1060-h18.html