1060 mirror aluminum plate

the 1060 Mirror Aluminum Plate: A Reflection of Versatility and Elegance

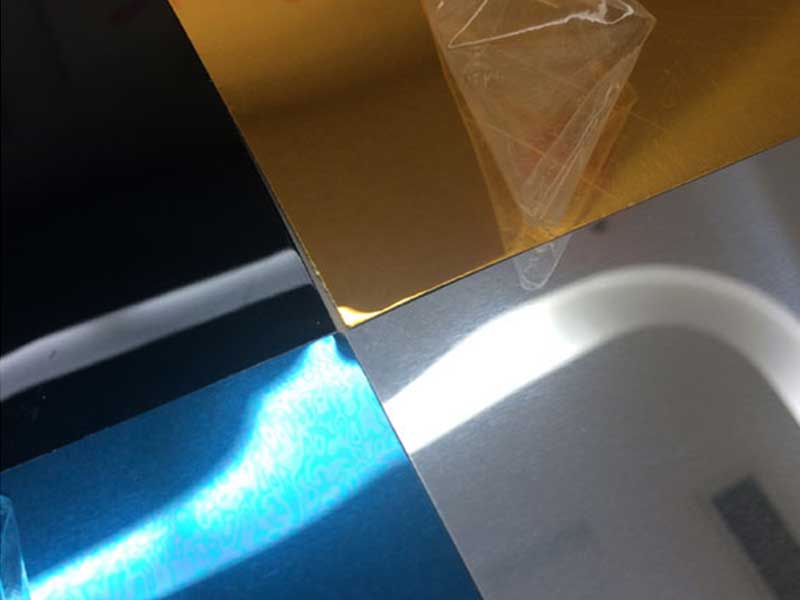

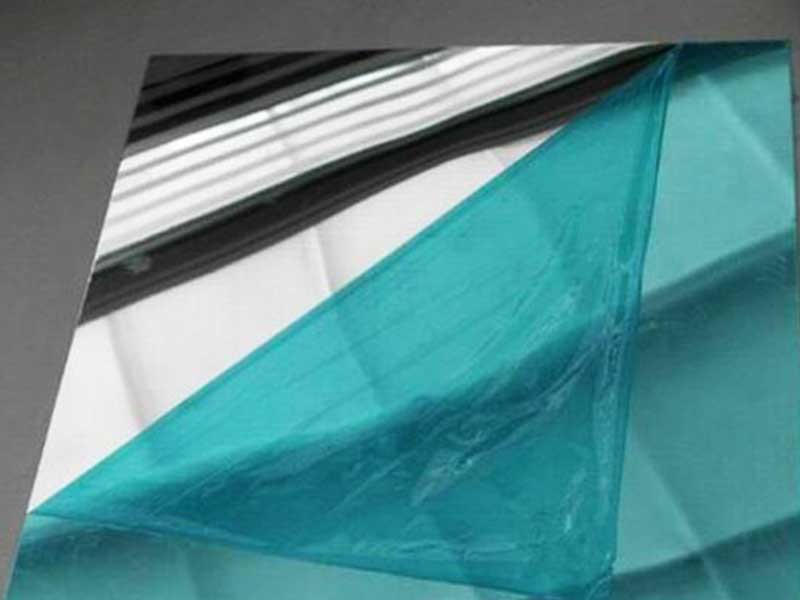

In the world of industrial materials, functionality often meets aesthetics, and nowhere is this union seen more beautifully than in the 1060 mirror aluminum plate. Though its name might suggest simplicity, this plate is a showcase of ingenuity, craftsmanship, and multifaceted usability. Today, we are diving into its unique attributes and applications, striving to peel back the layers that set the 1060 mirror aluminum sheet apart.

What is the 1060 Mirror Aluminum Plate?

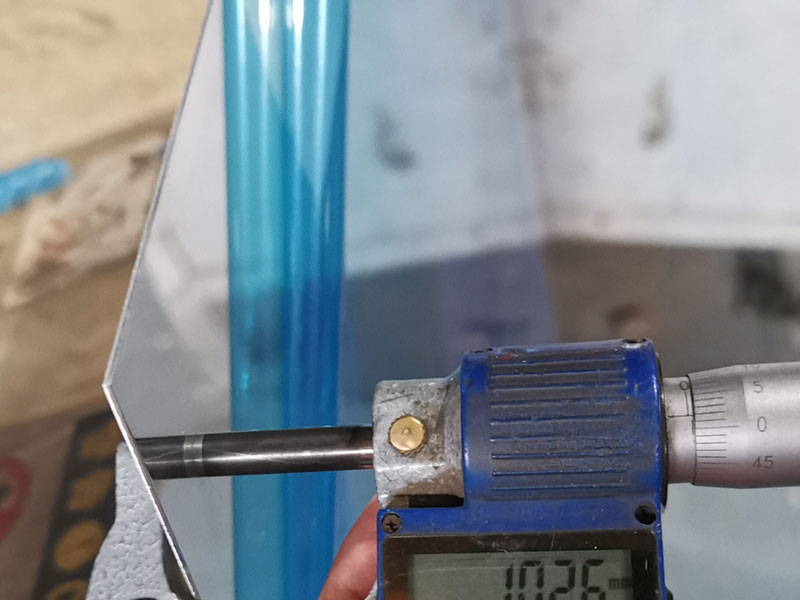

At its core, the 1060 mirror aluminum plate is crafted from aluminum alloy characterized specifically by its 99.6% aluminum content. In essence, this comprises the ingredient necessary for achieving exemplary reflectivity—the feature of mirror aluminum.

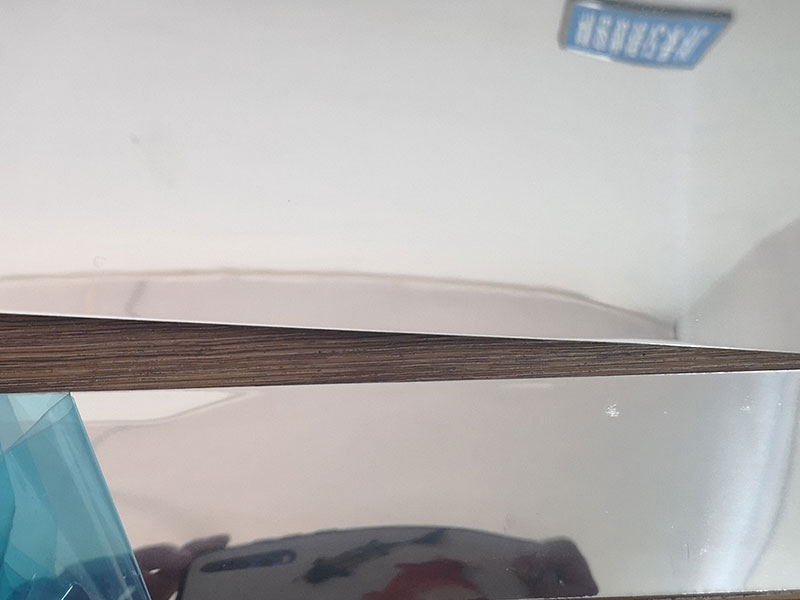

The number “1060” signifies the alloy type, heavily influencing properties such as ductility, corrosion resistance, and overall malleability. Alongside its stunning reflectivity, this means the plate can be easily processed to fit diverse structural demands.

The Beauty is Not Just Skin Deep: The Technical Side

Let’s get into the nitty-gritty. One of the territories where the 1060 mirror aluminum plate shines—literally—is thermal conductivity. Remarkably efficient, this type of aluminum conducts heat effectively, promoting its use not only for dictation of thermal properties but also ensuring reduced energy consumption in necessary applications.

When you pay close attention to the attributes, it’s easy to appreciate how the chemical stability of high-content aluminum contributes to an enhancement of the beauty associated with traditionally mindful architecture and modern design. Its lightweight nature allows for structural advantages while maintaining strength—making it a preferred option for many engineers and designers looking for materials that don’t weigh down the overall resolution.

Applications Beyond Aesthetics

Many people firstly consider this type of aluminum for its appealing look and reflective surface—homely décor, art installations, or elegant retail displays. However, a broad range of applications accentuates its functional prowess:

-

Architectural Design: Buildings and installations utilize mirror aluminum plate as façade materials, instantly upgrading the aesthetic appeal while boosting energy efficiency.

-

Consumer Electronics: Many gadgets gain both elegance and characterization when fitted with mirror aluminum exteriors, bringing sleek designs to gaming tables and telephone casings alike.

-

Automotive Parts: Traditionally, materials endure classification effects over performance. Still, reflective hydrographic therapy through mirroring finishes via aluminum interiors blend safety for the end-user alongside visual flair.

-

Signage and Displays: Mirror aluminum not only catches the eye in showcases but also printed advertising distills strong brand impressions characterized by durability and stainless illusion—the nutrients needed to yield memorable impressions.

-

Lighting Solutions: Due to its excellent reflection properties, the 1060 mirror aluminum plate finds a role in lighting applications too. They serve as reflective surfaces in light fixtures, elevating aesthetic style while enhancing electrical enclosures.

https://www.aluminumplate.net/a/1060-mirror-aluminum-plate.html