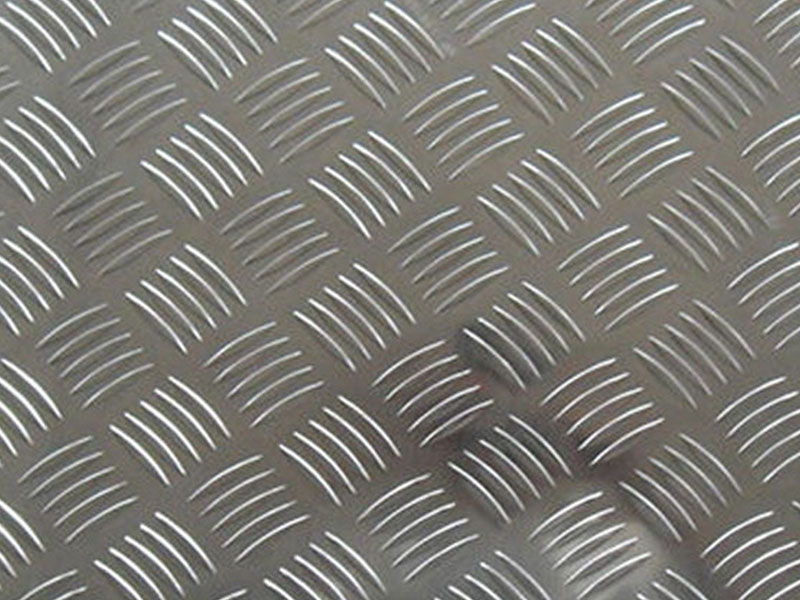

5 bar aluminium checker plate

Aluminum alloy products have carved out a significant space in the construction, transportation, and manufacturing sectors. Among the multitude of aluminum offerings, the 5 bar aluminium checker plate stands out not just for its aesthetic appeal, but also for its functional characteristics. Whether you cross paths with it on a flooring system or a vehicle ramp, its impact bleeds into various domains—let's unravel the essentials of this versatile material.

What Is 5 Bar Aluminium Checker Plate?

The 5 bar aluminium checker plate is a specific form of aluminum sheet featuring a series of raised surface patterns etched in five distinct bars. This elegant yet rough surface design allows for slip resistance, reducing the instances of accidents in wet or oily environments. The embossed bars not only serve a safety function but elevate the sheet's stylistic quality, rendering it an excellent choice for both functional and decorative applications.

Parameters and Standards

Aluminum checker plates are typically available in a range of thicknesses that can range anywhere from 1.0 mm to over 10.0 mm. However, for the 5 bar variation, the common thicknesses are between 2.0 mm to 6.0 mm. Standard length and width measurements can vary, but a typical sheet is coming in 2440 mm x 1220 mm dimensions.

Implementation and Standards:

The use of 5 bar aluminum checker plates must adhere to specific industry standards, ensuring quality and safety match the critical operations they host. The most significant standards in this field include:

- ISO 9001 for quality management systems

- ASTM B209 for aluminum and aluminum-alloy plate and sheet

- Aluminum Association Standards, establishing classification and chemistry requirements

Alloy and Tempering

This material is generally produced from various grades of aluminum known for their unique characteristics many involving mechanical strength, plasticity, and wture resilience:

Typical Alloys Used:

5052: Known for its moderate to high strength properties along with excellent corrosion resistance which is critical in marine environments.

5754: Offers high tensile strength and low density, making it ideal for heavy-load-bearing applications.

6061: Prominent in structural applications; it also combines the best properties of strength and finish.

Temper Designations:

The enduring performance of the checker plate is further enhanced through the tempering process, which affects its hardness and yield strength:

- H14: Strain-hardened and partially annealed.

- H32: Strain-hardened and stabilized by low annealing.

Each temper yields specific qualities that align with the application needs, from general fabrication to structural usesousing.

Chemical Properties

The distinct environmental persistence of the 5 bar aluminum checker plate can be excelled using general chemical constituents. Here’s a short reference table indicating the typical compositional balance in alloys yet delineates essential properties:

| Element | Symbol | % Composition (Typical aluminum alloy pois) |

|---|---|---|

| Aluminum | Al | 90-96% |

| Magnesium | Mg | 0.5-3% |

| Manganese | Mn | < 1%. |

| Silicon | Si | < 0.6 desc%. |

| Iron | Fe | < 0.7% |

| Copper | Cu | < 0.3% |

Additional Considerations

When considering the application of 5 bar aluminum checker plate, it's important to review potential curing actions such as anodizing or painting. Provided coatings not only amplify anodic protection but enhance surface appeal besides contributing to longevity against atmospheric elements.

Wrap-Up: An Annotation of Versatility

All in all, the fabrication and deployment of 5 bar aluminum checker plates webers hold valuable implications onto industries broad in deployment but specific extremeities in durability same expo and passions typically intend dismissed basics installations. Continue the thorough dive to create insights on the mechanical specs related upon adhering refining detailing across checking additives, coating competences concrete productivity.

https://www.aluminumplate.net/a/5-bar-aluminium-checker-plate.html