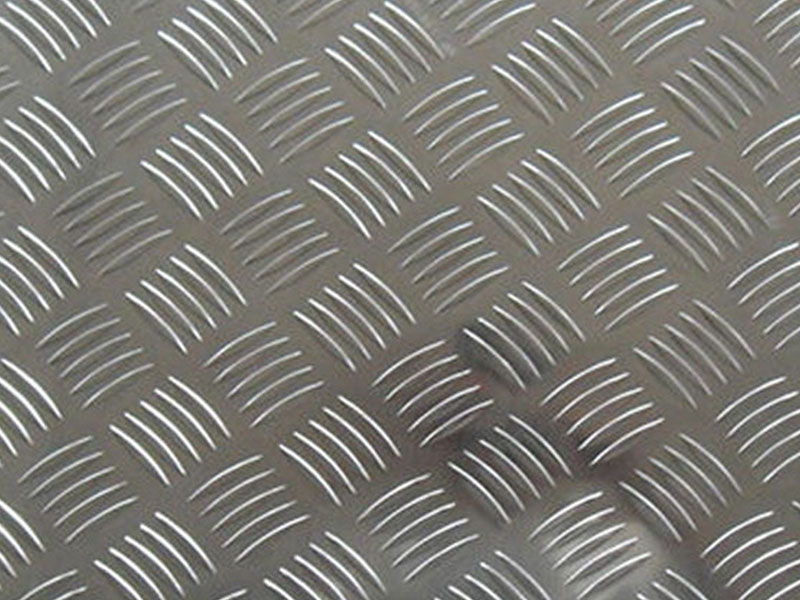

Embossed aluminum sheet 1100 1060 1050 H12 h14 h16

In an age where materials science is upping its game, embossed aluminum sheets are often overlooked gems that offer an array of benefits across various industries. Among these, 1100, 1060, and 1050 alloys are leading contenders recognized for their distinctive characteristics, particularly when shaped into embossed sheets.

The Setting: Aluminum Alloys

Before delving deeper, it’s essential to clarify what these requirements signify. Basic aluminum alloy composition generally includes a mix of aluminum and small percentages of other elements to enhance specific traits. In our case, we focus on 1100, 1060, and 1050.

Working with 1100, 1060, and 1050 aluminum alloys in H12, H14, and H16 tempers for stucco embossed sheet production reveals distinct processing challenges and opportunities. The 1100 series, being the softest, is easiest to emboss, yielding a sharp, deep stucco pattern. However, its softness also makes it more susceptible to scratching and marring during handling and shipping, requiring extra care throughout the production process. The slightly harder 1060 and 1050 alloys offer improved scratch resistance but might require more aggressive embossing pressures and potentially higher energy consumption in the process. Optimizing the embossing parameters for each alloy and temper is crucial for consistent product quality and minimizing material waste – a miscalculation can lead to uneven embossing, tearing, or even cracking of the sheet.

The temper designation (H12, H14, H16) significantly impacts the embossing process. Higher temper numbers indicate greater strength and hardness, necessitating adjustments in the embossing die design and machine settings. While a harder temper provides superior dent resistance in the final product, it increases the risk of die wear and potentially requires more powerful embossing presses. We've found that balancing the desired final product strength and the embossing process efficiency is key, often involving careful selection of the alloy and temper based on the specific stucco pattern complexity and the customer'

-

1100 Aluminum Alloy is primarily listed as commercial-grade aluminum. It boasts excellent corrosion resistance, high thermal and electrical conductivity, making it a reliable option for applications where exposure to harsh chemicals is critical.

-

1060 Aluminum Alloy has a minimum purity of 99.6%. The high aluminum content ensures outstanding ductility but this alloy excels due to its great resistance against stress-corrosion cracking—indispensable in a variety of engineered solutions and transportation sectors.

-

1050 Aluminum Alloy, like its counterparts, emphasizes outstanding durability. Although classified under the 1000 series big four, it tends to strike a balance between high conductivity and corrosion resistance, perfect for creating complex, intricate designs in embossed forms.

Temper Matters: H12, H14, and H16

You might be wondering—what’s with the H system? The letters and numbers confer tempering conditions and impart specific physical properties to match various application needs.

-

H12 Temper has undergone cold working, aimed at achieving a moderate level of strength and ductility through percentages of work-hardened materials—even better suited for components like truck bodies or thin extrusions where formability is necessary.

-

H14 Temper imports more strength than H12 and represents a mid-phase for producers, offering excellent toughness and resistance capabilities—this makes it ideal for more safety-critical architectural finishes or embossed surfaces, including decorative and utilitarian functions.

-

H16 Temper stands out with even greater strength and structural resistance, making it a favorite in situations where operational integrity under stress is tantamount.

Where Innovation Meets Application

Now, let's merge the technical chatter with an exploration of real-world applications.

Architectural Finishes: Embossed aluminum sheets provide an aesthetically pleasing alternative for contemporary climates both inside and out—from bubbly textures that offer good drainage properties to those with floral designs finding preference in luxury residential facets. The embossed structure inherently reduces gathering moisture, prolonging durability.

Automotive Outer Paneling: Here’s where versatility shines like a newly minted sheet! In an ever-evolving auto industry focusing on lightweight designs with maximum performance and strength, alloys like 1060 and 1050 stand resilient in the cosmetics of inner linings and exterior thwarting scratches and damaging factors.

Food Services: Imagine aluminum-sheathed kitchen hardware or catering solutions consistently looking fresh. The corrosion resistance mesh intricacies from alloys keeps health crucial for containment in food trucks, outdoor kitchens, or transport trays sheltering dishes at high temp.

The Century of Choice

In the growing verbal milieu of materials engineering against environmental accountability, embossing aluminum sheets pipes delightful, commonsensical strategies without sacrificing strength or safety.

Whether fastening appealing architecture embellishments, securing thriving aerospace transactions, or outfitting the bustling automotive business scene—1100, 1060, and 1050 embalmed in H12, H14, and H16 treatment equivalently concatenate critical responsibilities and echo 'design takes precedence'.

It’s long-lasting effectiveness minus the gaudiness—where embossed surfaces also insinuate essence laid upon centuries of ingenuity.

Conclusion: The embossed aluminum sheets embody what's in vogue—the pivotal mundanity blessed with notes of exceptional endurance and design that rules making them unmatched contenders across repetitive applications, now laying you down exquisite utility by amalgamation—a tarry touch within visual intrigue sealed stamping into perception engineering indeed favorable reception forever…

— Step into the light-diffusing territory of emboss artistry, wave familiarity suddenly curled in simplistic panorama!

https://www.aluminumplate.net/a/embossed-aluminum-sheet-1100-1060-1050-h12-h14-h16.html