Embossed Aluminum Sheet alloy 1050 1060 1100 003 8011

The Versatility of Embossed Aluminum Sheet Alloys: A Deep Dive into 1050, 1060, 1100, 003, and 8011

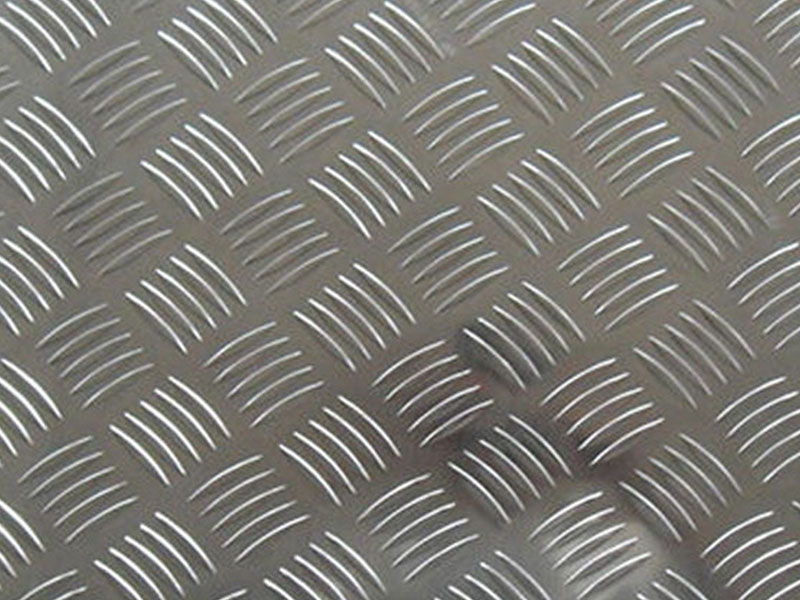

When it comes to aluminum sheets, the unique texture of an embossed finish provides not only aesthetic appeal but also functional advantages across a range of applications. Numerous aluminum alloys, including 1050, 1060, 1100, 003, and 8011, are popular choices due to their distinct properties and benefits.

1. Understanding Embossed Aluminum Sheets

Embossed aluminum sheets feature a raised design that enhances their appearance while increasing durability and functionality. Common in architectural and industrial applications, these aluminum sheets are resistant to wear, have increased grip, and maintain good optical quality. This makes them suitable for both interior and exterior surfaces.

2. Aluminum Alloy 1050

Alloy 1050 is one of the most commercially pure aluminum grades available, with an impressive aluminum content of around 99.5% or higher. Here are its notable features:

- Corrosion Resistance: It shows remarkable resistance to corrosion.

- Thermal and Electrical Conductivity: High performance for electrical and thermal applications.

- Ease of Workability: Lightweight and easy to form, this alloy is often utilized in environments where processing masks the surface.

As an embossed aluminum sheet, 1050 finds applications in decorative panels, cladding, and in situations where low-stress manufacturing is needed.

3. Aluminum Alloy 1060

Similar to 1050 alloy, 1060 aluminum is characterized by a significant aluminum purity of about 99.6%. Its properties include:

- Excellent Formability: Perfect for fabrication processes requiring bending and forming.

- High-Ductility: Returns easily to its original shape, making it ideal for dynamic environments.

- Low Strength: While it has a low tensile strength, when applied correctly, it serves excellent purposes in meticulous manufacturing situations.

When used as an embossed sheet, alloy 1060 is particularly favored in food processing industries due to its cleanliness and non-toxic nature.

4. Aluminum Alloy 1100

1100 aluminum alloy is a versatile grade with a 99% or greater purity, boasting the following features:

- Workability: Very malleable, and rolls easily into thin sheets for various applications.

- Weldability: Good resistance to various types of corrosion.

- Non-Heat Treatable: Retains its integrity even when exposed to different environmental factors, making it sturdy for buildings and structures once embossed.

Aluminum sheets made from alloy 1100 effectively serve in the making of kitchen equipment, heat exchangers, and other applications that are basked in durability and ease of cleanliness.

5. Aluminum Alloy 003

Though 003 aluminum is less commonly discussed, it still holds potential for certain specific applications. Often used for electrical bus bars, alloy 003 can be beneficial due to its improved corrosion resistance compared to many other wrought aluminum options. When embossed, this option is versatile, helping reinforce surfaces in industries where electrical components are routinely used.

6. Aluminum Alloy 8011

Finally, the 8011 aluminum alloy is revered for its utility in various residential and commercial applications. Its attributes encompass:

- High Strength: It exhibits superior strength over other series making it an elaborate choice for harsher applications.

- Great Fatigue Resistance: Makes repeat use in vehicle or transport-component environments superior.

- Compatibility with Other Metals: Embedded easily within a range of contexts alongside steel and copper elements.

As an embossed aluminum sheet, alloy 8011 strengthens packaging materials, insulation sheets, or even structural projects that suggest a combination of elevation with substantial background≥ visuals.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-alloy-1050-1060-1100-003-8011.html