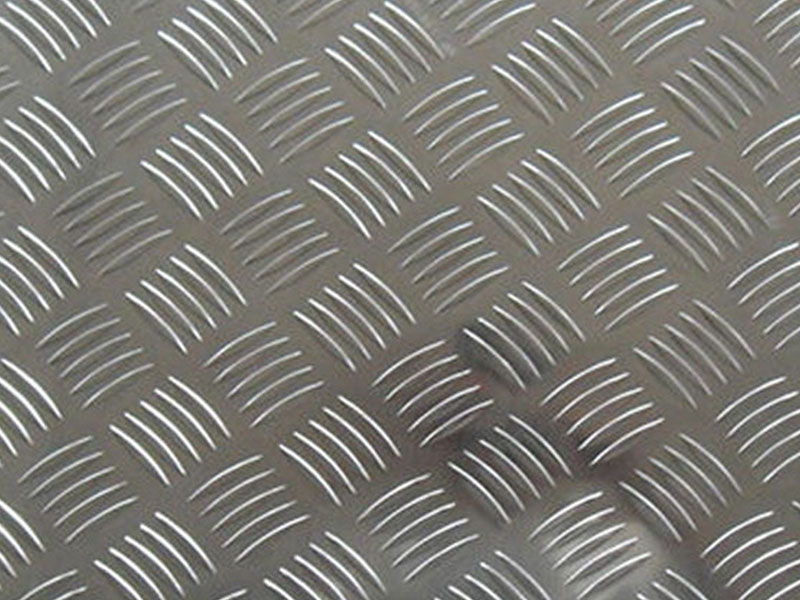

Aluminum tread plate 1060 1050 1100 3003 3004 3005

Aluminum Tread Plate Grades 1060, 1050, 1100, 3003, 3004, and 3005: Functional Excellence and Versatile Applications

Aluminum tread plates are renowned for their combination of lightweight durability and anti-slip properties, making them a top choice across industrial and commercial applications. Yet, what sets the different aluminum alloys apart—specifically grades 1060, 1050, 1100, 3003, 3004, and 3005—is how each grade’s unique chemical composition and mechanical properties prepare them for specialized roles.

the Technical Backbone of Aluminum Tread Plates

Aluminum tread plates are production sheets distinguished by a raised diamond or other patterned relief surface, which ensures stable foot traction and prevents slippage in many tough settings. But to truly appreciate their premium functionality, it’s essential to recognize how their respective grades influence factors like strength, corrosion resistance, formability, and affordability.

Here’s a closer examination:

Grades 1050, 1060, and 1100: The 1000 Series – Purity and Formability Focus

-

1050 Aluminum Tread Plate: Containing approximately 99.5% aluminum, Grade 1050 boards achieve exceptional ductility and electrical conductivity. While it’s somewhat softer and less strong than its peers, the alloy is prized for light-duty anti-slip uses—a perfect fit for weight-sensitive structural panels or decorative surfaces where easy formability is crucial.

-

1060 Aluminum Tread Plate: Slightly more refined than 1050, Grade 1060 highs in purity often exceed 99.6%, pushing even greater malleability. Because of this, 1060 plates are commonly applied in custom structural projects, like ramps, walkways, and truck flooring designs, where complex bending and shaping prove essential.

-

1100 Aluminum Tread Plate: The most heavily used pure aluminum alloy with ≥99% purity. Benefiting from remarkable corrosion resistance combined with excellent workability, 1100-grade plates offer superior fatigue strength. They’re ideal for indoor and mildly abrasive outdoor settings—like food processing plants or interior architectural elements that demand hygiene alongside walkability.

Grades 3003, 3004, and 3005: The 3000 Series – Added Strength Without Sacrificing Corrosion Resistance

These alloys revolve around the aluminum-manganese-magnesium combination, enhancing mechanical performance while retaining anti-corrosion benefits and weldability.

-

3003 Aluminum Tread Plate: Integrating roughly 1.2%-1.5% manganese, grade 3003 delivers higher tensile strength (about 130–180 MPa) versus pure alloys. Its steady corrosion resistance and excellentWorkability make it a workhorse for outdoor walkways, scaffolding, and vehicle floors where moderate wear and exposure prevail.

-

3004 Aluminum Tread Plate: Slightinch boost in manganese (~1.3%) and magnesium (~0.3%) pushes hardness and formability further. Suitable for transportation platforms, shipping containers, and aftermarket industrial van floors, 3004 performs well under repeated impacts and exposure.

-

3005 Aluminum Tread Plate: Chromed by enriched magnesium content (approximately 0.5%), grade 3005 boasts the highest strength within these 3000-series options and carries enhanced resistance to staining and bright film formation. Innovations seen in naval or heavy industrial environments leverage this strength for scrub decks, marine hatch covers, or heavy fabrication parts.

Why Selecting the Right Aluminum Tread Plate Alloy Matters

Each alloy offers specific advantages relative to function—whether maximized formability for shaping 1100-grade sheets or elevated tensile strength in the magnesium-increased 3005 series. Moreover, their corrosion resistance coupled with desirable fatigue tolerances prime these sheets for use under demanding operational loads without costly maintenance.

Functionally, aluminum tread plates act as both anti-slip floorings and structurally supportive materials in architectural features, elevation-raising vehicle parts, defense armor bases, and beyond. For example:

-

Construction and Safety Walkways: Increased grip for elevated walkways, stairs, and platforms reduces workplace incidents.

-

Transportation Industry: Durable truck and trailer flooring withstand repeated mechanical stress and weather.

-

Marine Applications: Corrosion-resistant grades (3004/3005) offer reliable surface solutions for decks and hatches crafted for salty environments.

-

Food and Beverage Facilities: Easy to clean, stands up to frequent floor washing cycles and maintains sanitary compliance with highly pure grades.

-

Decorative Architecture: Grade flexibility enables rounded patterns, architectural forms, and quality surface finishes without sacrifice.

https://www.aluminumplate.net/a/aluminum-tread-plate-1060-1050-1100-3003-3004-3005.html