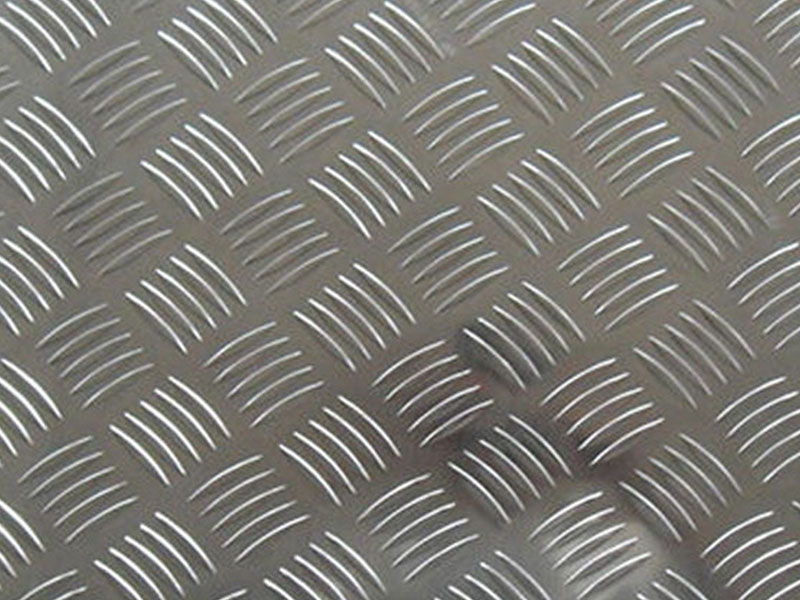

Embossed Aluminum Sheet alloy 1050 1060 100 3003 8011

When it comes to aluminum sheets, embossed options have become increasingly popular due to their distinct properties and aesthetic appeal. In particular, embossed aluminum sheets made from various alloys, such as 1050, 1060, 1100, 3003, and 8011, provide exceptional resistance to wear and corrosion, making them ideal for a wide range of applications.

Understanding Aluminum Alloys

Before diving into the details of scratched Aluminum Sheet alloys, it's beneficial to underline the importance of alloy specifications. Aluminum alloys mainly consist of two types: non-heat-treatable and heat-treatable alloys. The popular aluminum alloys 1050, 1060, 1100, 3003, and 8011 fall within the non-heat-treatable group, each possessing unique properties suitable for specific applications.

Characteristics of 1050, 1060, 1100, 3003, and 8011 Aluminum Alloys:

-

Alloy 1050: Known for its high purity (over 99% aluminum), Alloy 1050 offers excellent corrosion resistance and conductivity. It is often used in food and chemical processing environments, requiring minimal risk of reactions due to its inert properties.

-

Alloy 1060: Similar to 1050, Aluminum 1060 features a slightly higher strength machined with enviable ductility and thermal conductivity. These traits make it a suitable choice for a variety of decorative applications, closures, and electrical conductors.

-

Alloy 1100: With good corrosion resistance and formability, Alloy 1100 is commonly used for chemical storage tanks, food processing, and pressure vessels. The aesthetic appeal of embossed sheets offers added texture that enhances their signature properties.

-

Alloy 3003: Generally considered the most widely used aluminum alloy, 3003 combines strength with exceptional workability. The addition of manganese provides improved stress corrosion cracking resistance, making it ideal for fabrications and painted finishes.

-

Alloy 8011: Particularly popular in the aluminium foil industry, Alloy 8011 showcases high strength and corrosion resistance. While typically seen in food packaging, its embossed forms have expanded into construction and insulation uses.

Applications of Embossed Aluminum Sheet Alloys

Embossed aluminum sheets serve countless possibilities across various industries. Here are some of the lead sectors that benefit from these unique materials:

-

Architecture: In architectural applications, embossed aluminum sheets provide aesthetic appeal while significantly improving the rigidity and versatility of systems, such as fence companies, wall panels, and roofing materials.

-

Automotive: The automotive industry often utilizes embossed aluminum sheets for interior and exterior trims, floor mats, and fuel tank shielding, benefiting from both improved aesthetics and functional resilience.

-

Food and Beverage Storage: Given their properties, many food and beverage companies choose embossed sheets embodying alloys like 1050 and 3003 for cabinets, containers, and freezers.

-

Electrical Applications: Producers of electronics and electrical components leverage the thermal and electrical conductivity of alloys 1050 and 1060.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-alloy-1050-1060-100-3003-8011.html