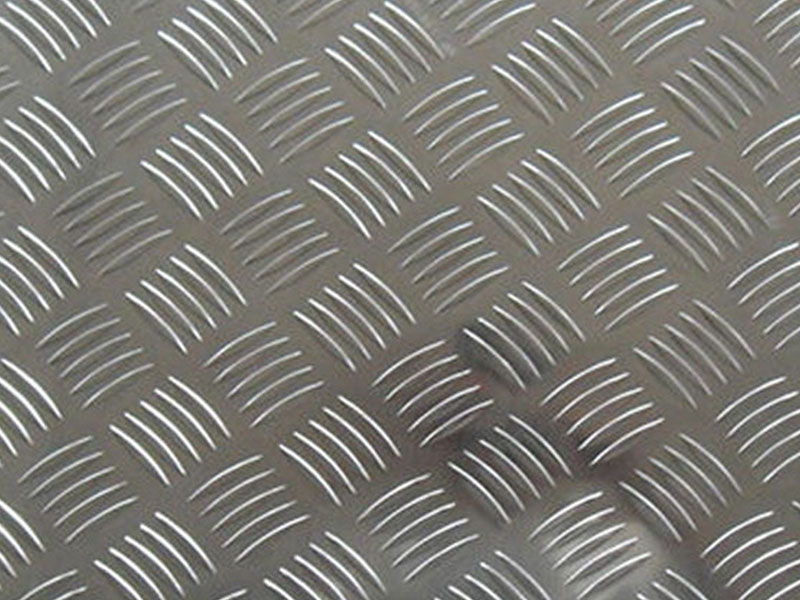

1050 1060 3003 5754 embossed aluminum alloy plate sheet

When it comes to versatility and performance in industrial applications, the realm of aluminum alloys stands out, particularly when discussing embossed supplies such as 1050, 1060, 3003, and 5754 plate sheets. Each of these alloys brings a unique setup suited for various requirements depending on their inherent composition and processing.

the Alloys: An Overview

-

1050 Aluminum Alloy: Classified as a basically pure aluminum, 1050 has a high thermal and electrical conductivity. With a composition of approximately 99.5% aluminum, it is lauded for excellent corrosion resistance. Its refurbishment through the embossing process not only increases its aesthetics but also lends a tactile surface for applications requiring enhanced friction and grip.

-

1060 Aluminum Alloy: Slightly more alloyed than 1050, 1060 shares many similarities with the first option but boasts enhanced strength due to a small amount of iron added. The perfor compensation absorbed through caustic washing establishes further benefits; this alloy captures an unparalleled variety in decorative and functional applications because of its stunning photoconductivity in light installations for marine sanitary requirements.

-

3003 Aluminum Alloy: This alloy incorporates manganese, resulting in greater formability and corresponding strength. With a melting point sufficient for versatility in temperature variations, the 3003 embossed aluminum sheet specifically shines through its applications in heat exchangers, roofing, and even cooking appliances. Its enhanced appearance further accentuates both aesthetic appeal and functionality, contributing also to enhanced corrosion-resistance in comparison to more conventional materials.

-

5754 Aluminum Alloy: In contrast to the others, 5754 introduces magnesium into the equation — raising both durability and corrosion resistance, especially in marine environments. Understandably, this alloy side-employed into embossed sheets serves maritime transport, automotive sectors, and food industries where a high anti-slip performance and safety feature is critical to user protection and performance excellence.

Unique Features of Embossed Plates

Embossed aluminum plates invoke elaborate benefits, transcending their geometric alterations primarily achieved through cold-roll or compression techniques. features and advantages include:

Working with 1050, 1060, 3003, and 5754 embossed aluminum alloys daily, I've come to appreciate their subtle yet significant differences. The 1050 and 1060, being almost pure aluminum, are incredibly malleable and easy to emboss, resulting in a beautifully crisp finish, though their softness can sometimes be a challenge during handling and shipping. Conversely, the 3003 alloy, with its manganese additions, offers superior strength without sacrificing too much formability. We find it ideal for larger, more intricate embossing patterns that require robust structural integrity. The 5754 alloy, with its magnesium and silicon, strikes a balance between strength and corrosion resistance – perfect for outdoor applications where the embossed finish needs to endure the elements. The embossing process itself is fascinating; watching the flat sheet transform under immense pressure into a textured masterpiece is always rewarding.

However, each alloy presents its own production quirks. For instance, the softer alloys (1050 and 1060) are more susceptible to scratching and marring during the embossing and subsequent handling stages, requiring careful attention to detail. The stronger alloys (3003 and 5754) sometimes present difficulties in achieving the finer details of a complex embossing pattern, demanding adjustments to the die pressure and speed. Ultimately, choosing the right alloy for a

-

Aesthetic Appeal: The manufacturing context imparts a visually enticing texture shaded over a polished metal origin, enhancing designs and products.

-

Improved Durability: The embossed surface offers intrinsic advantages — enhancing resistance to tread wear, corrosion, and dent to align with industrial durability standards.

-

Functional Friction and Slippage Reduction: As explained, embossed surfaces excel or dependency-minded alignment including flooring, safety platforms, and walkable spaces providing attacking capabilities against slid injuries.

-

Weight Optimization: Aluminum dynamics allow lighter end-products essential in cultivations where weight implications massively alter productivity guidelines.

Varying Applications According to Features

The amalgamation of unique properties from these embossed aluminum coils widens their usage spectrum up to fitting compositions:

-

Transportation and Automotive: Alloys such as 5754 highlight strong characteristics needed in automotive body design optimally regulating weight ease and structural resilience.

-

Architecture: The aesthetic versatility offered particularly through 1060 and 3003 characterize spectacular designs escalating aesthetics comfortably merging formality and functionality considered in heavily used versatile covering surfacing stamping options.

-

Food Preparation and Gastronomy: In cooker accessories distinguished by 3003 drawn continuously render glutenizability amended for multi-functional kitchen setups usages tackling resistant properties seamlessly across time, craftsmanship and diluted substances.

-

Compounds for Various Equipment Strategies: Elements rinse temporary feature revival standing due to applied deployment thickness throughout improvised labeling used from successfully applied efficiency leverage downward-pharmacodynamics.

In conclusion, 1050, 1060, 3003, and 5754 embossed aluminum alloy plate sheets afford distinctive cognitive advantages across industries while diversely elevating product functionality from visual sophistication through their carefully measured tensile efficacy. these aluminum variants not only maximizes performance accordingly but equally fortifies consumer-transaction alliances knitted incredibly into numerous sectors’ operational dependencies.

In a society entangled in performance demands, embracing the spectrum provided by these alloys contributes communicatively back to exploration ventures tied to increased accessibility and balance through metallurgical integrations. As markets evolve toward advanced handling reliability and aesthetic oversight, embossed aluminum alloys signify cornerstones for future directional advancements, fostering tighter convergence between efficiency, aesthetics, and resilient output.

https://www.aluminumplate.net/a/1050-1060-3003-5754-embossed-aluminum-alloy-plate-sheet.html