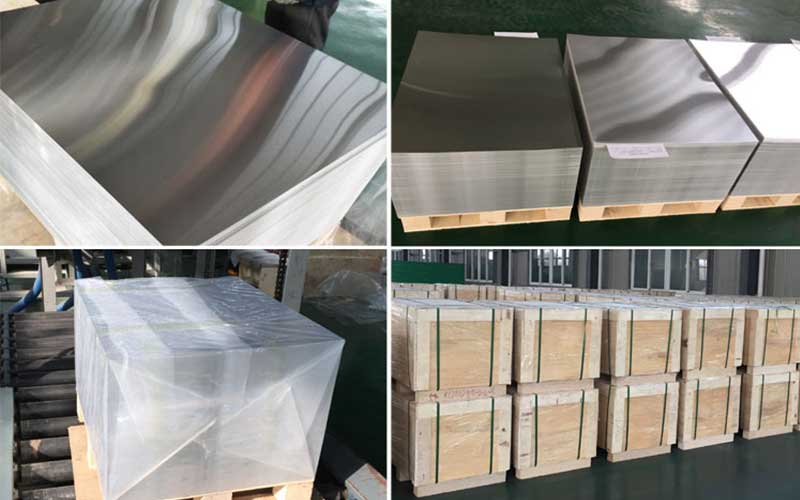

Aluminum coil for PS plate 1060 factory

the Creative Horizons: Aluminum Coil for PS Plate 1060

In the dynamic realm of modern printing technology, the prominence of Aluminum Coil for PS Plate (Photopolymer Plate) 1060 has risen substantially. This aluminum alloy is not just a basic material but remains a core component in a wide range of applications designed to enhance printing processes.

The quality of the aluminum coil is paramount in the production of high-quality Aluminum CTP (Computer-to-Plate) plates. In our 1060 aluminum coil factory, we've found that inconsistencies in the alloy composition, even minor deviations, directly impact the final plate's performance. Specifically, variations in grain size and texture significantly affect the plate's ability to accept the image during the imaging process. Too coarse a grain can lead to poor image resolution and dot gain, while too fine a grain can make the plate susceptible to scratches and damage. Therefore, rigorous incoming inspection, focusing on chemical composition and metallurgical analysis, is crucial, far beyond simple thickness and width checks. We meticulously track coil source and batch to identify any trends correlating specific coils with performance issues in the final product.

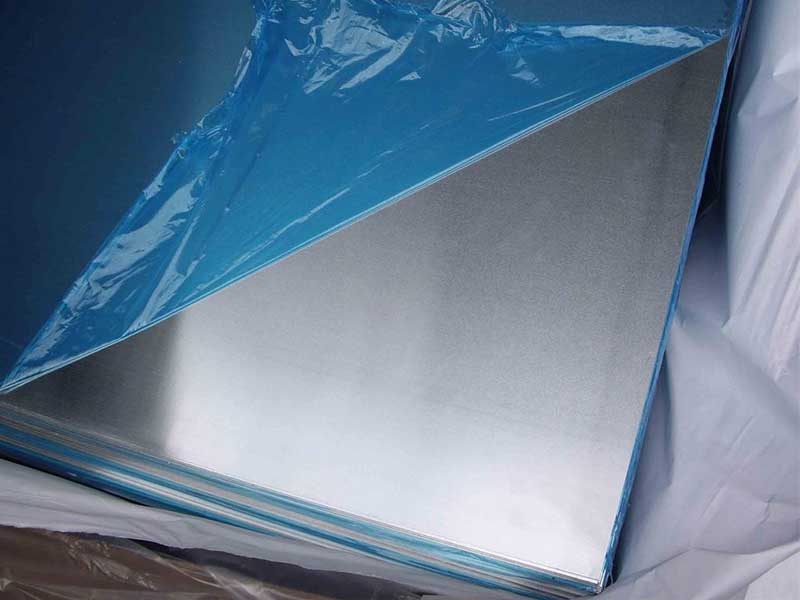

Beyond material consistency, the coil's surface finish plays a vital role. Even microscopic imperfections can interfere with the imaging process, leading to printing defects. We've learned that optimized surface treatments applied to the coil before processing greatly improve the final product’s quality and reduce waste. Careful control of cleaning processes and surface treatments is essential for achieving the desired balance of hydrophilicity and hydrophobicity crucial for accurate image transfer. This necessitates close collaboration between the coil production and CTP plate manufacturing teams, sharing data on surface properties and identifying optimal parameters for consistent plate performance. Ignoring this close relationship often results in increased production costs due to waste and rejections

PS Plates and Their Significance

Photopolymer plates, commonly known as PS plates (Positive System plates), are utilized in offset printing as they marry high-resolution imaging capabilities with a chemically stable framework. The adoption of Aluminum Coil specifically in PS plates comes with the 1060 grade, famed for its excellent purity and machinability.

ALUMINUM 1060:

-

Composition: Aluminum 1060 consists of 99.6% standard aluminum content, a highly ductile element that lends itself well to plate fabrication without fractures or breaks.

-

Technical Attributes: The main features include excellent reflectivity, remarkable wear resistance, and compatibility with various coatings that confer additional surface attributes.

These properties empower PS plates to respond flexibly to the evolution of modern corrugated or flexible printed packaging applications, empowering industrial printing capabilities.

Functions of Aluminum Coil in PS Plate Plates

-

Support Structure: The aluminum coil serves as a support structure allowing the images etched into the plate materials during the exposure process to adhere seamlessly. The rigid and durable nature of Aluminum 1060 fold makes it an outstanding candidate for offset printing.

-

Heat Conduction: Aluminum has fantastic thermal properties that ensure even distribution of heat during exposure. This translates into nuanced details in printing with vibrant color preservation, setting a standard in print quality.

-

Corrosion Resistance: An inherent attribute, thanks to aluminum's natural oxidation, protects the plates from corrosive exposures, which is critical for several printing establishments engaged in high-volume print runs.

-

Recyclability: Moving ahead towards environmentally friendly practices, aluminum coils are 100% recyclable. Any residue of the aluminum coils from the production process can be repurposed, thereby reducing wastage.

Applications of Aluminum Coil for PS Plate 1060

-

Commercial Printing: users of PS plates incorporate them not just in newspapers, periodicals but introduction of aluminum plates helps achieve exceptional print clarity and sophistication in general offset printing products.

-

Flexographic Printing: Companies specializing in high-end packaging prefer Aluminum 1060 due to reliability and capacity to handle numerous wash-ups without losing sharpness holes.

-

Label Production: With consumers seeking appealing labels, aluminum PS plates ensure spectacular imagery and guide increased marketless sales when presented on everyday products like beverages and packaged food items.

-

High-Speed Printing Applications: PS prints in High-Speed Emboss-struck Production reducing printing mistakes and enhancing color matches through aluminum coil reflective properties that apart forms an advantageanced production approach.

https://www.aluminumplate.net/a/aluminum-coil-for-ps-plate-1060-factory.html