6mm Mirror Finish Anodized Aluminum Sheet

In a world where both durability and aesthetics play critical roles in materials selection, mirror finish anodized aluminum sheets radiate a profound versatility. Among these, the 6mm variant stands out for both its creative potential and structural resilience.

1. Aesthetic Appeal Beyond Shine

Often, surface appearance is a critical determinant when architects or designers conceptualize spaces. The unique shimmering quality of the mirror finish anodized aluminum not only adds decorum but also amplifies light in innovative ways. The flawless reflective surface has the ability to create optical illusions, thus transforming the environment around it. Wherever used, it can brighten interiors by reflecting light and generating an atmosphere linked with space and comfort. The 6mm thickness ensures enough robustness for installations, providing stability while accentuating form.

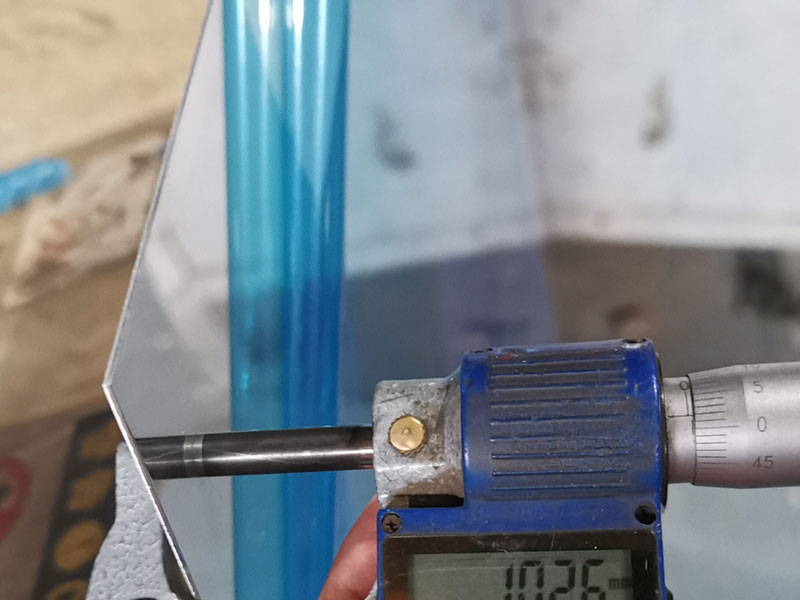

Working with 6mm mirror finish anodized aluminum sheet is a fascinating blend of precision manufacturing and surface science. We're not just dealing with a simple metal sheet; it's a highly engineered product demanding meticulous control at every stage. The 6mm thickness itself requires specialized rolling equipment to achieve the desired flatness and dimensional accuracy, and any imperfections are amplified by the mirror finish. The anodizing process, which involves creating a protective oxide layer, is crucial. We need to perfectly control factors like voltage, current density, and bath temperature to ensure a uniform, durable, and truly reflective surface. A minor variation can result in noticeable blemishes, streaks, or inconsistencies in the final product – something our quality control team is constantly vigilant about. Seeing a perfectly finished sheet, reflecting flawlessly, is a rewarding experience that highlights the collective precision and skill involved in its creation.

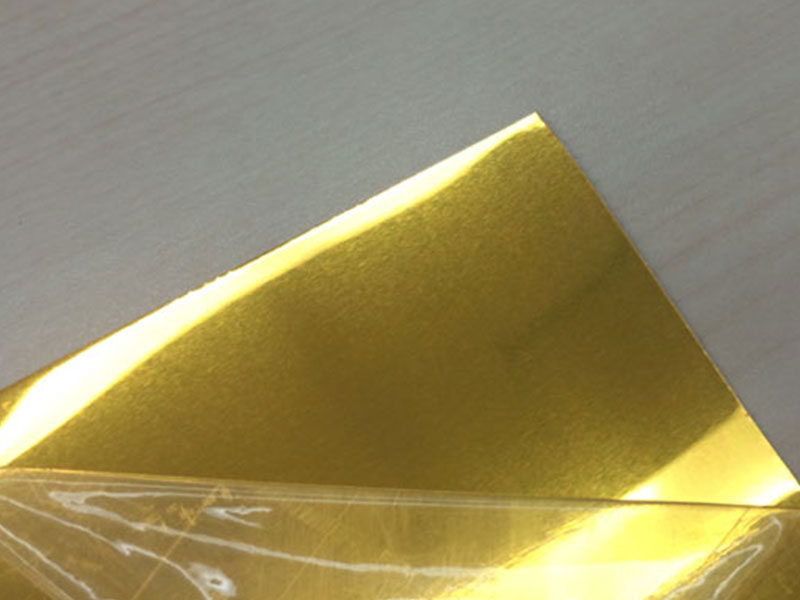

The specific challenges of this material also make it particularly rewarding. For example, the extremely reflective surface requires specific handling and storage to prevent scratching and smudging, impacting everything from production line design to the packaging we use. We’ve experimented with different types of protective film and handling techniques to minimize damage during transport. Furthermore, the demand for consistency in color and reflectivity is extremely high, especially for applications requiring optical precision. This pushes us to constantly refine our processes and improve our of the underlying chemical and physical phenomena involved in aluminum anodization and surface finishing. It's

2. The Science of Unexpected Durability

Most individuals may compare thickness alone with sturdiness while overlooking the vital anodization process. Anodizing enhances corrosion resistance thanks to the electrochemical treatment that converts the metal surface into a durable oxide layer. This sheathing provides additional endurance against scratching, UV rays, and oxidation – challenges frequently faced in outer environments. This robust encapsulation also helps reservoir the metal from environmental wear—a crucial aspect for exterior uses in architectural applications, allowing structures to retain their luminous finish much longer than conventional materials.

3. Versatile Applications: Modern Architecture to Unique Artwork

The use of 6mm mirror finish anodized aluminum sheets extends far beyond mere decoration; it exudes functionality that makes it ideal for various applications such as siding panels, ornamental displays, kitchen furnishings, and even artistically crafted motifs. For instance, strategic placement on building facades creates functional artworks subconsciously fusing reflective properties to redefine space, giving perception even to smaller polygons. Furthermore, contemporary artists use it to push boundaries, interactivity via reflection—transforming surfaces into catalysts for timeless expressions.

4. An Environmentally Calling Card

Sustainability concerns are reshaping our world, extending into the very qualities of the materials we choose. This attribute features prominently in the selection of 6mm mirror finish anodized aluminum sheets. Just by virtue of aluminum being one of the most recyclable metals—with a reduction of a budgetary constraint greater than ever. The anodization process, being less harmful to the environment than many other surface treatments available today, signifies a commitment to sustainability in industrial design initiatives.

5. Maintenance and Longevity: Rent the Shine

Despite maintaining aesthetic proficiency and enduring several onslaughts of recent elements, subjected installations require honest upkeep. The easy maintenance make the 6mm mirror finish anodized aluminum sheet an easily sustainable option.

A mild detergent alongside effusion of a little warm water suffices as a standard maintenance practice, leaving surfaces echoing their original glory year after year. Due to its resistant surface that hampers buildup, recurrence and cyclic obligation reduce progressively.

https://www.aluminumplate.net/a/6mm-mirror-finish-anodized-aluminum-sheet.html