Alloy 1070 Mirror Reflective Aluminum Coils

In the world of aluminum alloys, few materials can boast the exceptional qualities of Alloy 1070 mirror reflective aluminum coils. While aluminum is widely celebrated for its durability and versatility, Alloy 1070 stands out because of its unparalleled reflectivity and purity. this alloy not only enables professionals to optimize their manufacturing processes but also influences various applications from decorative finishes to advanced engineering projects.

Unveiling Alloy 1070

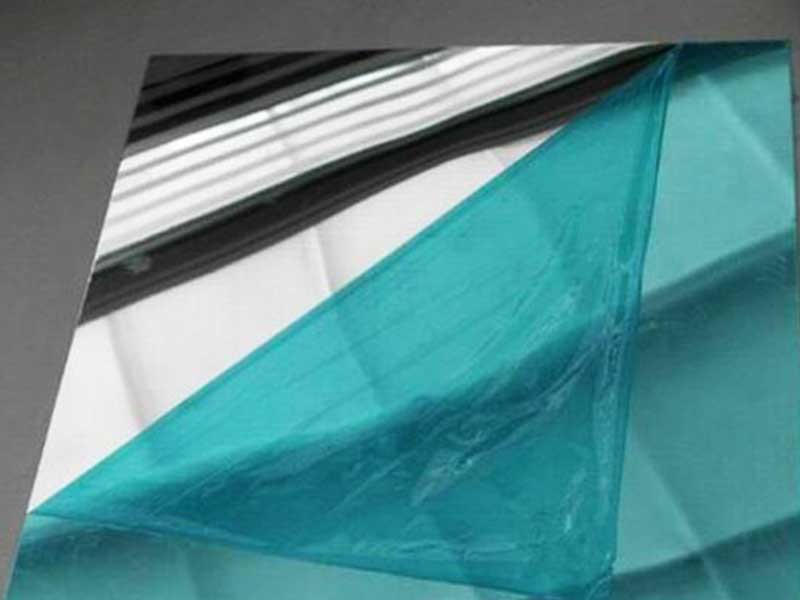

Aluminum alloy 1070 is primarily composed of 99.7% aluminum purity, leading to some of the highest levels of reflectivity available in the industry. When produced as a mirror reflective aluminum coil, the surface undergoes treatment to enhance its brightness and luster, making it remarkably effective for applications requiring light management.

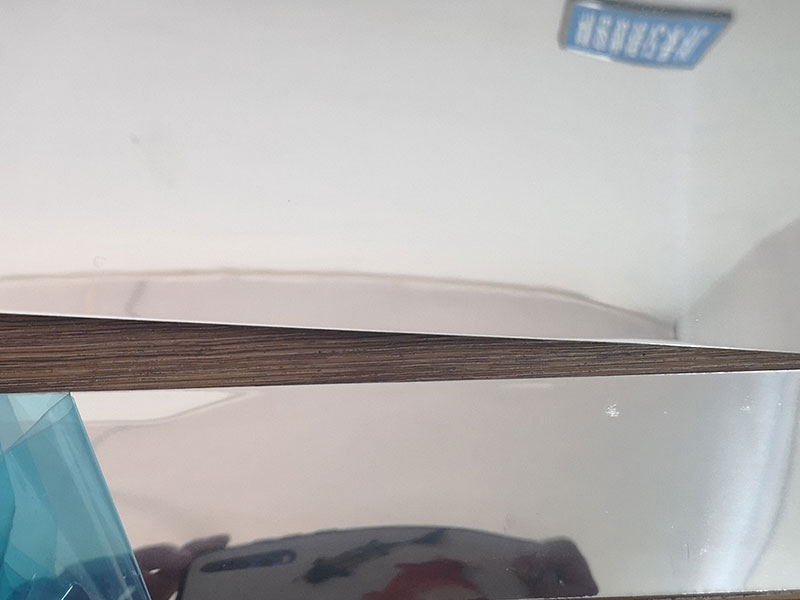

Alloy 1070, while offering excellent formability and corrosion resistance, presents unique challenges in achieving a truly superior mirror finish on coils. Its high purity contributes to a bright surface, but the inherent softness means that even minor surface imperfections, from rolling irregularities to handling scratches, are readily apparent after polishing. Therefore, stringent quality control throughout the entire production process, from casting and rolling to final inspection, is paramount. We've found that optimizing the annealing process is critical for achieving the desired grain structure for superior reflectivity, and even subtle variations in temperature or time can significantly impact the final product. Investing in advanced surface inspection technology, beyond the standard visual checks, allows for the early identification of subtle flaws, preventing defects from propagating through to the finished coil.

Our experience shows that the success of 1070 mirror reflective aluminum coils hinges not just on the alloy itself, but on the meticulous control of every stage of manufacturing. For instance, the choice and maintenance of polishing equipment significantly influences the final reflectivity. A well-maintained system reduces the risk of surface damage, while the correct choice of polishing compounds and techniques directly impacts the uniformity and brilliance of the final product. We've seen significant improvements in yield and quality by employing rigorous training programs for our operators and investing in preventative maintenance schemes for our machinery. Minimising handling and ensuring a clean, controlled environment throughout the process are essential in preventing surface contamination, ensuring consistent high-quality mirror reflective coils

The Unique Properties of 1070 Mirror Reflective Coils

Exceptional Reflectivity

One of the primary reasons why Alloy 1070 is the material of choice for manufacturers producing mirror reflective aluminum coils is its reflective percentage, which can reach up to 90%. This means less absorbed heat and efficient light propagation, making popular applications include:

- Lighting fixtures: Enhance the intensity of lighting by manipulating surface reflective properties.

- Architectural designs: Elevate aesthetic appeal without sacrificing functional performance.

- Photography and decorative surfaces: Maximize light utilization, leading to high-quality outputs.

Formability & Fabrication

Thanks to the alloy's workability, the production of mirror aluminum coils in Alloy 1070 not only affords opportunities for reflective greatness but also ensures ease in further fabrication. With a balanced combination of tensile strength and ductility, this alloy is readily processable without compromising its unique properties, making manufacturing easy in fields such as:

- Construction

- Automotive

- Home appliances

Technical Insights: The Fabrication Process

The journey of Alloy 1070 from raw aluminum to an industrial product begins with rigorous extrusion and rolling practices in a temperature-controlled environment. The result is coils produced in various gauges, tailored to each client’s requirements.

-

Cold Rolling Process: This process ensures thickness consistency and desired finishes. Enhanced thickness tolerances contribute to robust products without interrupting reflectivity standards.

-

Surface Treatment and Polishing: Advanced surface treatment processes ensure the coil not only shines but stays protected against oxidation, helping maintain visual and functional quality over time.

-

Quality Control: Products are subjected to various inspections to assess their thickness uniformity, gloss levels, and structural integrity. This meticulous attention to detail guarantees that clients receive the highest quality standard expected of mirror reflective aluminum coils.

Applications Beyond Illumination

The applicability of Alloy 1070 also extends beyond mere aesthetics and decorative elements. Applications across industries harness the interplay of reflectivity, functionality, and durability thatfit into multiple project requirements:

- Heat Shields: Alloy 1070 helps manage and dissipate heat effectively in critical environments, enhancing performance for engineering tasks in machine casings and cabinets.

- Solar Reflectors: Capitalizing on reflectivity, this alloy finds favor in solar panel backing, returning maximal utility from collected sunlight.

Sustainable Manufacturing and Eco-Friendly Mindset

The qualities of Alloy 1070 mirror reflective aluminum coils don’t just entice surface admiration. As industries push towards sustainability, manufacturers have looked at ways to minimize their carbon footprint through (a) optimized energy consumption involved in processing this alloy, (b) recycling potential of anti-oxidative reflective surfaces, and (c) uptake in green architectural features that lead to efficient energy use.

The Bottom Line

Choosing Alloy 1070 for mirror reflective aluminum coils signifies more than situation; it signals a commitment to carrying integrity, sustainability, and aesthetic efficacy into a variety of script protocols. these technical diversifications provokes openness for better engineering solutions conducive to vast industrial fields.

In a whispered revelation within industrial innovation culture, Alloy 1070 mirror reflective aluminum coils combine technology with artistry—mirroring the future of aluminum peaks-ing, out-performing, and surpassing reflective standards expected by engineers and visionaries alike.

https://www.aluminumplate.net/a/alloy-1070-mirror-reflective-aluminum-coils.html