1060 050 1070 1100 Polished Aluminum Mirror Sheet

At the intersection of functionality and decoration, polished aluminum mirror sheets made from 1060, 050, 1070, and 1100 alloys hold a unique position in various industries. these grades — each with distinctive traits — can elevate your projects’ design and utility.

Aluminum Alloys

The choice of aluminum alloy is pivotal when selecting polished mirror sheets. Each alloy comes with specific advantages that cater to varying technical requirements:

Working with 1060, 050, 1070, and 1100 polished aluminum mirror sheets daily reveals a fascinating interplay between material properties and manufacturing processes. The subtle differences in alloying (e.g., the slightly higher copper content in 1100 versus 1060) noticeably affect the sheet's final reflectivity and workability. For instance, 1100 tends to be slightly more ductile, making it easier to form complex shapes without compromising the mirror finish, while 1060 might be preferable for applications requiring superior corrosion resistance. Maintaining consistent surface quality across these alloys is a constant challenge; even minute variations in polishing pressure or the type of abrasive used can significantly impact the final product's specular reflection. We often see slight differences in the "bite" of the polishing wheels, necessitating careful adjustment to guarantee a uniform, defect-free surface across the entire sheet.

-

1060 Aluminum: Renowned for its excellent corrosion resistance and high thermal and chemical stability, the 1060 grade exhibits outstanding workability. Its high reflectivity coupled with superb elasticity allows for applications ranging from decorative components to optical products.

-

1100 Aluminum: This grade is particularly versatile and provides an excellent combination of workability and corrosion resistance. As a softer alloy, 1100 aluminum allows for fine fabrication while still maintaining a high sheen. It is famously employed in the food and chemical industries due to its ability to withstand harsh environments without oxidizing.

-

1070 Aluminum: Often regarded as a preferred choice in mirror applications, 1070 aluminum provides exceptional reflectivity and thermal conductivity. Its ultra-pure content translates to a mirror-like finish suitable for lighting fixtures, reflex optics, and decorative mirrors.

-

050 Aluminum: This less common but still highly effective alloy is favored for its malleability and ability to receive a superior polish. It bridges the gap between the typical needs of general metal lacquer finishes and high aesthetic demands.

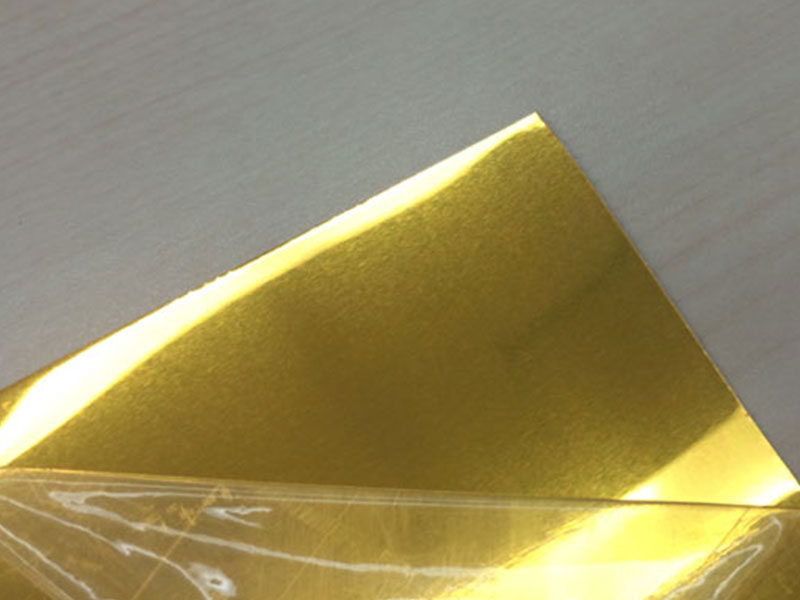

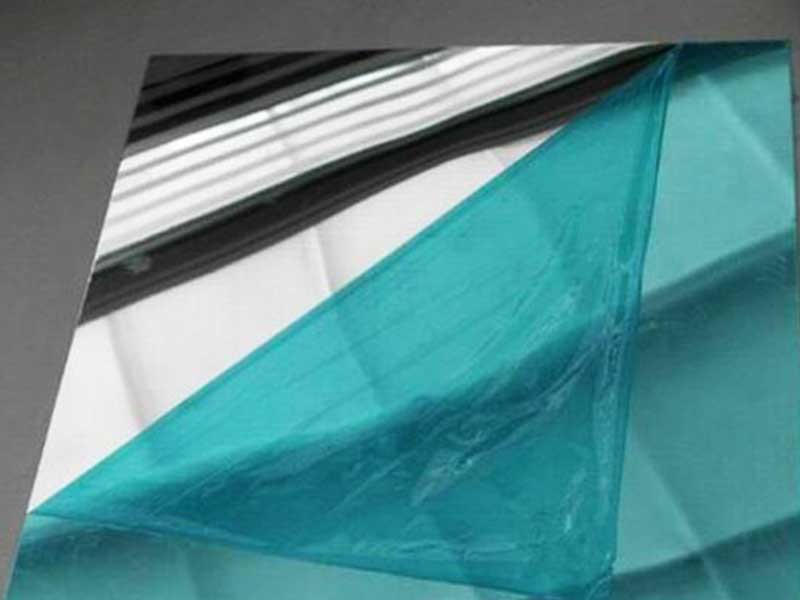

Polished Finish: A Definitive Advantage

The process of polishing these sheets is an art in itself. Achieving that gleaming surface requires more than just the gauge and anneal of alloys. Manufacturers employ advanced techniques that involve precision grinding, combined with complex chemical treatments. This elaborate polishing methodology ensures minimal scattering of light, providing unrivaled reflectivity that is quintessential in various applications.

Applications Cascade

Behind their brilliance, polished aluminum mirror sheets provide multiple advantages across industries:

-

Architecture and Interior Design: Anyone invested in aesthetics will agree that polished aluminum provides progressive design opportunities — from ceiling tiles to wall cladding, a bit of reflective aluminum stretches a utility space.

-

Automotive Uses: The automobile industry utilizes all four alloys not just for their aesthetic properties but also for weight reduction — making it an efficient choice that contributes to better fuel efficiency.

-

Lighting and Electrical: With 1070’s extraordinary reflective capabilities, mirrors serve various lighting mechanisms enhancing luminescence within dark spaces, soothing gradients for task lighting or art326culate environments.

-

Appliances and Home Use: The reliability and sleek nature of 1100 pedigree make perfect sense for mirrored accessories, bolstering everything from kitchen backsplashes to household appliances, enhancing items already engineered for effectiveness.

-

Reflective Highway Structures: Utilizing reflective sheets can bolster efficiency in erecting signaling stands and barriers, casting clear reflections needed to enhance visibilities at dodgy road segments.

Sustainability Meets Aesthetics

With increasing demand for eco-friendly materials, the aluminum alloy path opens many avenues for industry professionals. Such mirror sheets, particularly from the recyclability standing point, emphasize sustainable choices. Recycling aluminum utilizes significantly lower energy compared to raw aluminum production, propelling parks, construction sections, and drastic reduction in mean greenhouse gas emissions.

https://www.aluminumplate.net/a/1060-050-1070-1100-polished-aluminum-mirror-sheet.html