Aluminum tread plate For Roofing Pvdf Color Coated 1050

Enhancing Structures with Aluminum Tread Plate: The Unique Appeal of PVDF Color Coated 1050 for Roofing

In the ever-evolving world of construction materials, aluminum tread plate, particularly the PVDF color coated 1050 variant, stands out as a standout choice for roofing solutions. Known for its resilience and aesthetic appeal, this melodious combination revolutionizes roofing applications across commercial and residential buildings alike.

Using 1050 aluminum alloy for PVDF color-coated tread plate roofing presents a unique set of considerations. While 1050 offers excellent corrosion resistance, its relatively soft nature means it's less durable than other alloys like 5052 or 6061, particularly in roofing applications where it might experience foot traffic, hail, or debris impact. The PVDF coating adds significant protection against UV degradation and weathering, extending its lifespan, but proper surface preparation before coating is critical. I've seen instances where insufficient cleaning or pre-treatment led to premature coating failure, resulting in costly replacements. The lightweight nature of 1050 is a benefit for installation, simplifying handling and reducing structural loads, but careful consideration must be given to the fastening system to ensure secure attachment and wind uplift resistance, especially in high-wind areas.

Another aspect is the color consistency and longevity of the PVDF coating. While generally quite durable, variations in the coating process, exposure to harsh chemicals, or even improper cleaning methods can lead to discoloration or chalking over time. We've seen this particularly with darker colors which tend to absorb more heat, potentially affecting the coating's performance. Regular inspection and preventative maintenance, focusing on cleaning and addressing any minor scratches or damage promptly, can significantly extend the life of the PVDF coating and maintain the aesthetic appeal of the roof. Choosing a reputable PVDF coating supplier with

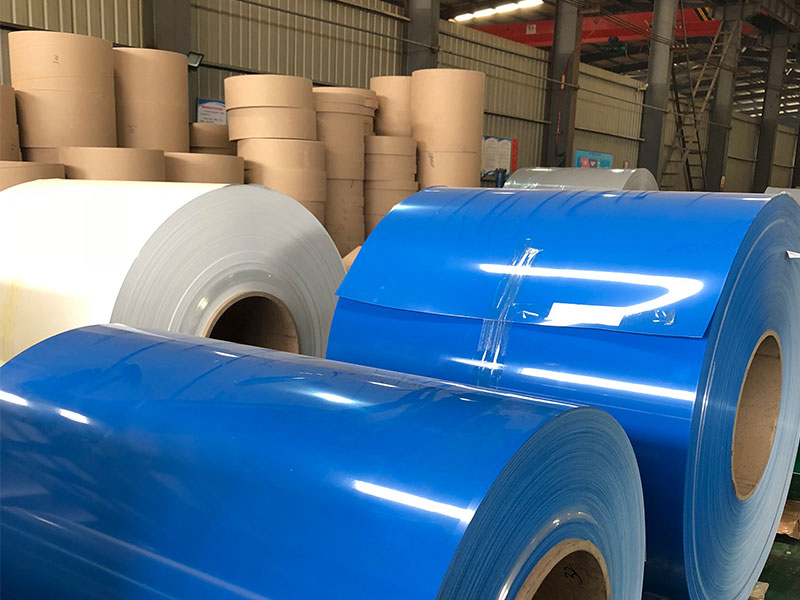

Aluminum Tread Plate

Aluminum tread plate, often known for its strength and non-slip surface design, is produced through a process of rolling aluminum sheets that incorporate specific patterns into their surface. This textured feature is pivotal, offering safety in high-traffic and industrial areas. While tread plate is recognized predominantly for applications in flooring and transportation, its value in roofing is evolving dramatically as businesses and architects seek durable, stylish materials that meet both performance and aesthetic parameters.

PVDF Color Coating: A Longevity Booster

The PVDF (polyvinylidene fluoride) color coating is a remarkable innovation in the field of metal finishing. Utilizing cutting-edge chemical properties, PVDF coatings excel in resisting scratches, deterioration, and environmental corrosion—ensuring the metal underneath remains protected for years. This means roofs adorned with 1050 PVDF color coated aluminum tread plate maintain their intensity and gloss, even when exposed to harsh weather conditions and UV radiation.

To put things into perspective, consider the 1050 designation: this number refers to the aluminum alloy’s belonging to the series that boasts exceptional corrosion resistance, thermal conductivity, and although it maintains a moderate tensile strength, its operational advantages far exceed the limits known to traditional roofing materials.

Functions and Applications in Roofing

1. Safety and Traction Enhancement: With safety being paramount, using aluminum tread plates embellishes roofing systems with functional advantages. Slips and falls on traditional roofing can pose substantial hazards, particularly in climates with substantial rainfall or sleet. The unique pattern of the tread plate provides inherent skid resistance, assuringmaintenance crews can work safely when accessing rooftops for inspections or repairs.

2. Aesthetic Uniformity: Beyond utilitarian value, PVDF coated aluminum tread plates are available in various colors and finishes. This chromatic flexibility allows architects to achieve preferred visual harmonies with the overall building design. From vibrant hues to subtle pastels, the finish on these plates can give a modern flair to buildings of any style—contemporary aluminum surfaces infused with a tailored color palette declare architectural confidence.

3. Lightweight Structural Integrity: Engagements with materials such as steel for roofing invariably lead to dealing with increased weight and ultimately the requisite support structures, while aluminum tread plate weighs far less. The alloy contains significantly lower density, roughly one-third than that of steel, ensuring roofing systems can accommodate minimalist construction strategies. This leads to cost-effective workloads while sustaining robust overhead support.

4. Sustainability Considerations: In today’s eco-conscious world, choosing Aluminum Tread Plate encompasses a profound environmental responsibility. Aluminium is one of the most recyclable materials available, allowing waste reduction and energy savings at subsequent processing stages. Moreover, the prolonged lifespan of coated roofing reduces the liabilities of frequent replacements, far(ecologically) offsetting any initial material use upfront.

5. Versatile Applicability: While many visualize tread plates as appropriate for warehouse roofing or commercial enterprises, their use expands far into bespoke residential projects. From garages to avant-garde urban loft designs, lively colors coupled with the tread pattern are equally chic and robust while effectively reflecting heat and reducing energy expenditures through naturally cooler attic spaces.

https://www.aluminumplate.net/a/aluminum-tread-plate-for-roofing-pvdf-color-coated-1050.html