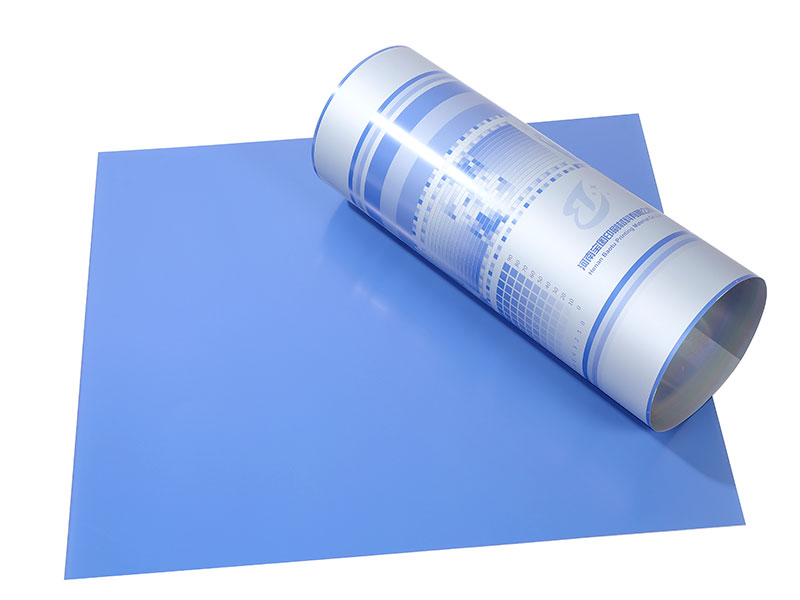

CTP Plates Offset Printing Plates Thermal Plate

Introduction: The Digital Shift in Printing Technology

In the evolving landscape of printing technology, the demand for high-quality revelations at fast turnaround times continues to escalate. At the crux of this dynamic is a standout innovation: Computer-to-Plate (CTP) technology, specifically thermal CTP plates. While many are familiar with the aesthetics and tactile aspects of printed materials, few know the essential role these plates play in the print production line. In examining CTP plates from a novel perspective, we'll unfold intricate details pertaining to their functionality, application scope, and adaptive qualities in offset printing.

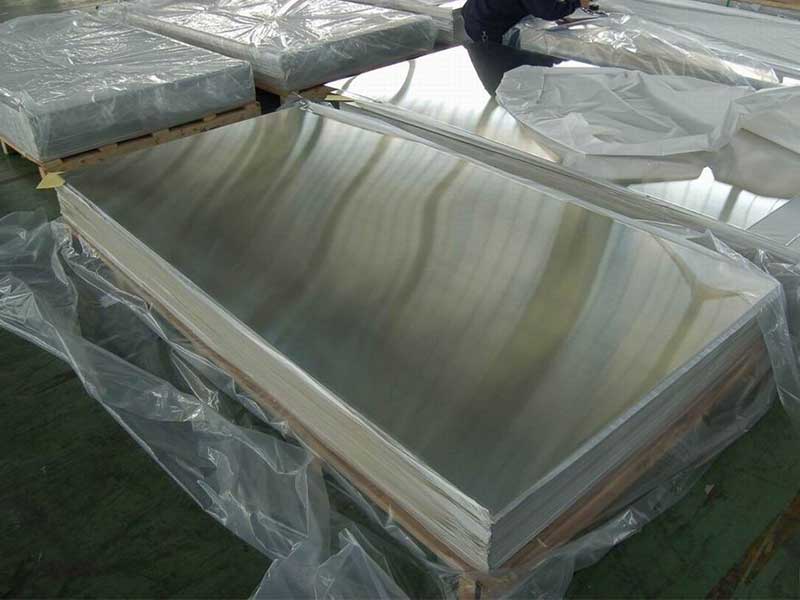

Working with aluminium CTP (Computer-to-Plate) plates daily, I've seen firsthand the evolution from the old photopolymer plates. The precision and speed are remarkable. We use thermal plates almost exclusively now, primarily due to the ease of processing and superior image quality compared to violet laser plates. However, the biggest challenge remains consistency in the aluminium substrate itself. Even minor variations in alloy composition or surface treatment can significantly affect the plate's performance, leading to inconsistencies in ink transfer and print quality. A seemingly small imperfection in the base material can manifest as a significant issue after processing and printing, highlighting the critical interplay between the plate's physical properties and the imaging process.

Personally, I'm fascinated by the ongoing advancements in thermal CTP plate technology. We're constantly experimenting with different plate types – varying in thickness, surface coatings, and the thermal sensitivity of the imaging layer. The goal is always better resolution, longer plate life, and faster processing times while maintaining affordability. Finding that sweet spot between these factors is a constant juggling act, requiring intricate of both chemistry and engineering. The future likely holds even finer resolution, potentially allowing for more detailed and complex prints, pushing the boundaries of what's achievable with offset printing.

The Splendor of CTP Plates in Offset Printing

CTP plates are an evolutionary move from traditional analog methods toward digital efficiency, offering exceptional precision and quality. Thermal plates harness heat exposure in an intelligent way, where digital imaging develops the plates intricately designed to maximize performance in offset lithography. this from a different viewpoint can illuminate not just the technology, but the conceptual genius worth appreciating in everyday operations.

Unpacking the Features: Precision Reinvented

-

Outstanding Imaging Quality: The thermal CTP process allows for higher resolutions (up to 2400 or even 4000 dpi), ensuring images and texts are replicated with remarkable clarity. This penchant for detail essentially presents unmatched lithographic reproduction hues.

-

Durability and Longevity: Both plate types boast excellent durability. However, thermal plates can withstand higher numbers of print runs without significant wear, resulting in consistent print outputs. This infrequently discussed perspective empowers businesses to lean on prolonged runs without the recurrent pressure of re-plate-making due to degradation.

-

Fast Processing Times: In efficiency, consider how-enhanced plate chemistry and laser-developed features vastly reduce setup times. Thermal CTP characteristics spread conveniently to larger print formats without compromising setup integrity energetically embraced quadrants of grown demands.

-

No Need for Water: While traditional plates typically require dampening systems—a complex part of many printing workflows—thermal CTP plates can be run processless. This is a game-changer in both environmental friendliness and operational simplicity, making them highly desirable for businesses reflecting modern sustainable ethics.

-

API-Compatible Technology: Incorporation within digital workflows is critical. Often, CTP systems arrive pre-aligned with API options for versatility across several design software platforms, allowing compatibility across multiple printers and reducing production bottlenecks.

Varied Applications: Crossing Industries

Thermal CTP plates break barriers, extending their value proposition well beyond traditional needs. Here are select industries reaping the nuances of enhancements provided by CTP sheets:

-

Commercial Printing: Widely employed for marketing and branding materials, insisting on fast turnarounds vibrant under detailed scrutiny fits into informational channels brought to creativity.

-

Book Publishing: Unique requirements from resolve concerns, spurring cost-friendly avenues where authors' works genuinely come to life come grippingly delightful.

-

Packaging: The particularly durable nature allows for imperfections in tactile packaging from several runs. Sustainability via processless plates matches emergent demands.

-

Labels: Thermal CTP plates excel in producing high-value indoor and outdoor Stick… The rapid printing schedule transports swift applications, enhancing fine piecemealed sensory experiences in either screen outputs cover labels unifying brand marketing.

https://www.aluminumplate.net/a/ctp-plates-offset-printing-plates-thermal-plate.html