CTP Plate (computer to plate, commercial printing plate, aluminum thermal positive plate)

The Evolution of CTP Plates: A Game Changer in Modern Printing

In the fast-paced landscape of commercial printing, innovation is the lifeblood that keeps the industry thriving. One such groundbreaking advancement is the development of CTP plates, or Computer-to-Plate plates. They have reshaped traditional printing methodologies and offer a slew of enhancements that serve both print professionals and clients.

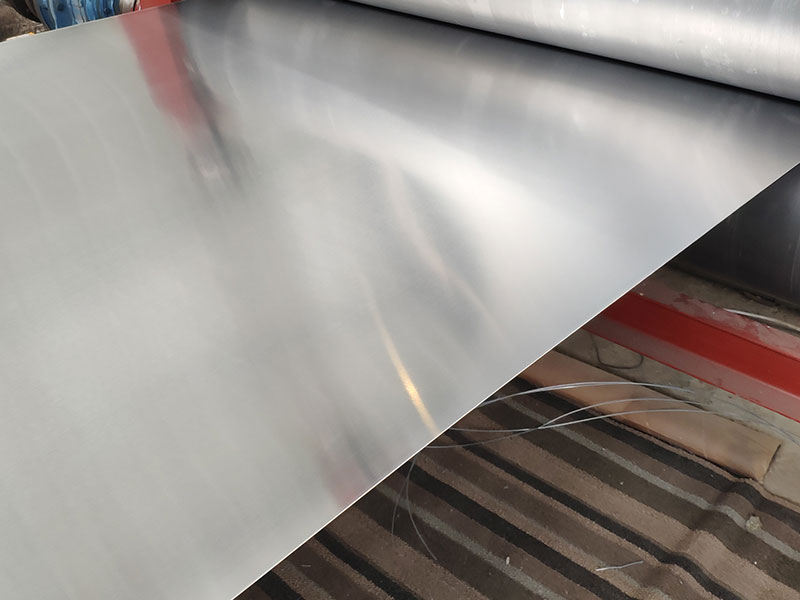

Working with aluminum CTP plates daily reveals a fascinating interplay between chemistry, physics, and precision engineering. The subtle variations in plate surface treatment, from the initial anodization process influencing image fidelity to the precise laser power settings determining dot gain and resolution, significantly impact print quality. We've found that seemingly minor changes in the pre-press workflow, like adjustments to the RIP settings or even the ambient temperature and humidity in the processing area, can drastically alter the plate's performance, leading to inconsistencies in ink transfer and potentially print defects like mottle or slur. these nuances, and constantly refining our process parameters based on feedback from the printing press, is crucial for optimizing plate lifespan and ensuring consistently high-quality prints.

Furthermore, the increasing demand for sustainable practices in the printing industry directly impacts our work with CTP plates. We're constantly evaluating new plate technologies that minimize chemical waste during processing, focusing on solutions with reduced environmental impact. This involves meticulous tracking of chemical consumption, alternatives to traditional processing chemicals, and collaborating with plate manufacturers to implement more environmentally friendly solutions. The pursuit of a greener footprint not only meets growing industry demands but also enhances our overall efficiency and reduces operational costs in the long run, making sustainable practices a crucial aspect of our plate production strategy.

What Are CTP Plates?

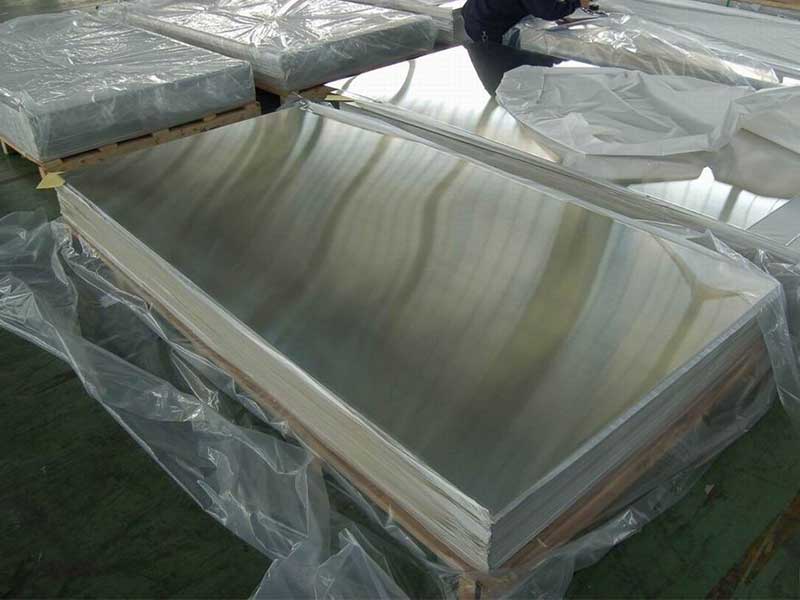

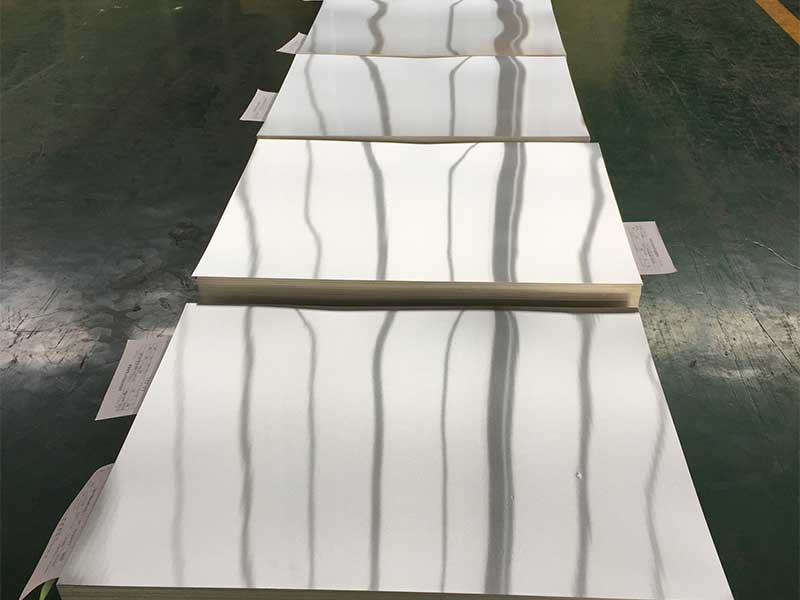

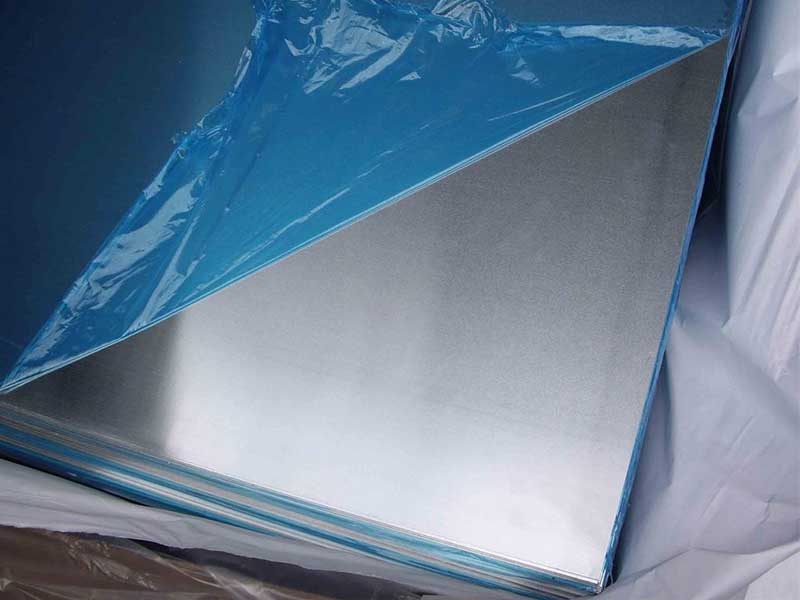

A CTP plate is a high-tech solution used in commercial printing that bridges the gap between digital data and physical printed products. Here, highly developed software and imaging technologies are employed to transfer images directly from a computer’s digital file onto a printing plate, most commonly made from aluminum. This method eliminates the need for traditional film negatives, increasing efficiency while maintaining high resolution and quality in prints.

Unique Features of CTP Plates

-

High Quality & Resolution: CTP plates provide superior resolution, ensuring sharp and vibrant images. This is particularly crucial for printing jobs where image detail is paramount, such as on flyers, magazines, and packaging.

-

Cost-Effective: By eliminating extra steps related to film development and reducing material waste, printers can significantly lower production costs. CTP plates offer a shorter setup time and diminished labor costs, making them a financially wise choice for commercial printing operations.

-

Consistent Quality: CTP technology enhances repeatability. Because the process utilizes computer-controlled imaging, the output remains haved each cycle, guaranteeing uniform quality across numerous print runs.

-

Reduced Environmental Impact: Conventional printing processes often waste materials in preparing and developing plates. With CTP plates, the need for film and additional chemicals is vastly diminished, leading to a more eco-friendly production line.

-

Speed & Efficiency: Modern presses leverage CTP plates for quicker job turnaround. Since prints are generated directly from the digital file to the plate, the production cycle is considerably faster—eliminating bottlenecks and enhancing client satisfaction.

Applications of CTP Plates

From packaging to publishing, the applications of CTP plates are vast and varied. Here’s where their utility shines:

-

Packaging Industry: The demand for dentless packaging solutions is skyrocketing. CTP plates enable companies to print beautifully detailed designs that are vital in both branding and regulatory compliance. From labels to food packaging, they provide exquisite detail that enhances product appeal.

-

Commercial Printing: Traditional printing businesses have integrated CTP printing technology to fulfill a variety of print needs—from brochures to business cards—quickly transitioning prototypes into full-scale production seamlessly.

-

Photobooks and Catalogs: In industries where visual aesthetics are critical, like fashion and architecture, CTP provides quality reproduction of color images, which are essential for visually-driven promotional materials.

-

Publication: Magazines and newspapers are leveraging CTP technology to keep pace with tight deadlines without sacrificing print quality, ensuring striking visuals and well-articulated messaging reach their audience effectively.

-

Digital Printers: CTP expands the limits of what digital printers can accomplish, allowing for vast and varied print opportunities. Small printing businesses can offer high-quality outputs normally reserved for large operations.