Positive Thermal CTP Plate with Long Run Length

Revolutionizing Printing: The Positive Thermal CTP Plate with Long Run Length

In today's fast-paced printing industry, efficiency and quality are paramount. The Positive Thermal Computer-to-Plate (CTP) technology has quickly implemented its presence as a sophisticated solution for high-quality image output. Among the most vital innovations in this sector is the Positive Thermal CTP Plate with Long Run Length, a versatile component engineered to deliver superior performance while addressing the evolving demands of modern printing workflows.

Positive Thermal CTP Plates

To fully appreciate the transformative role of Positive Thermal CTP Plates, it's essential first to understand their function. Utilizing laser technology, these plates expose an image onto a photopolymer surface, which then undergoes a series of chemical developments, resulting in a physical plate used for printing. The "positive" aspect refers to how the areas that are exposed to the laser become soluble in the processing solution, leading to the creation of a printing-ready plate with incredible accuracy.

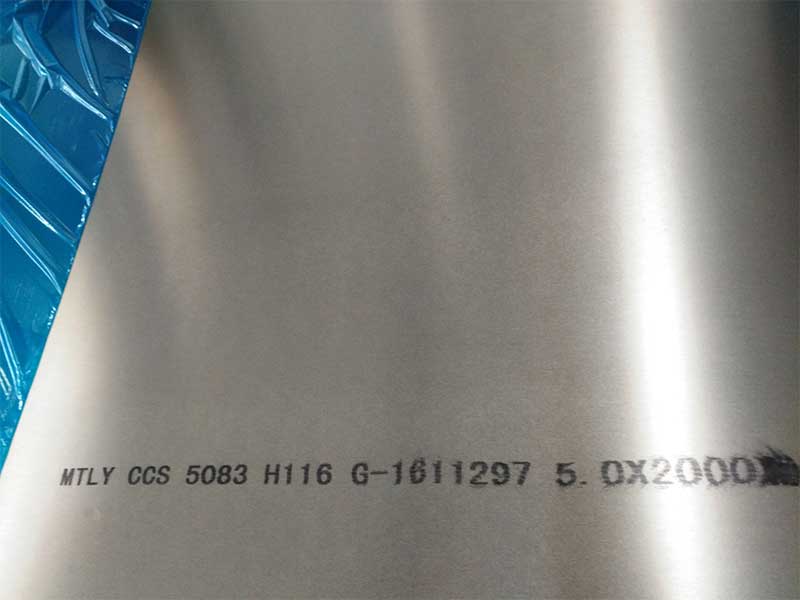

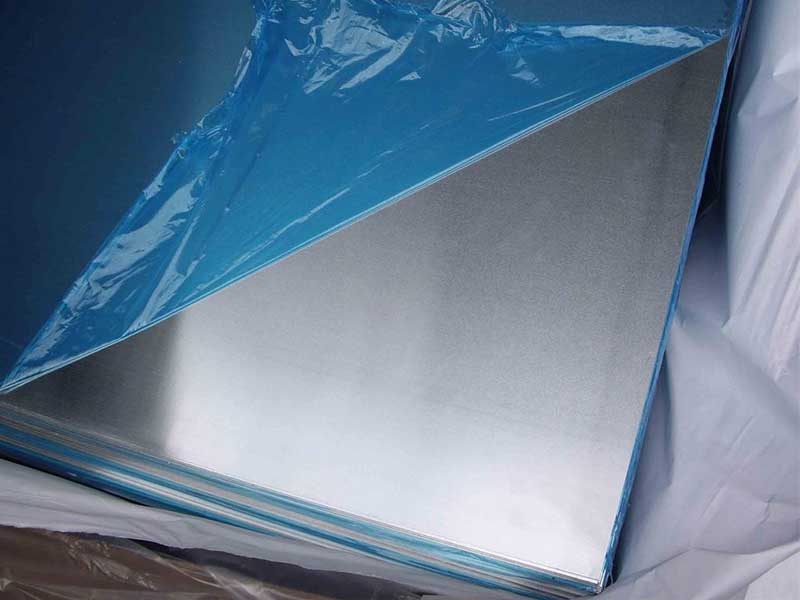

Working with positive thermal CTP plates, especially those boasting long run lengths, presents a unique set of challenges and rewards. We're constantly striving for that sweet spot: a plate that delivers crisp, consistent images for thousands of impressions without compromising on processing speed or incurring excessive waste. The higher the run length expectation, the more critical factors like plate stability and resistance to scratching or scuffing become. We meticulously monitor the chemistry of the developing process – even minor variations in temperature or concentration can significantly impact image quality and longevity across a long print run. Furthermore, press operator skill plays a crucial role; proper plate mounting and consistent press parameters are essential for maximizing the potential of these long-run plates.

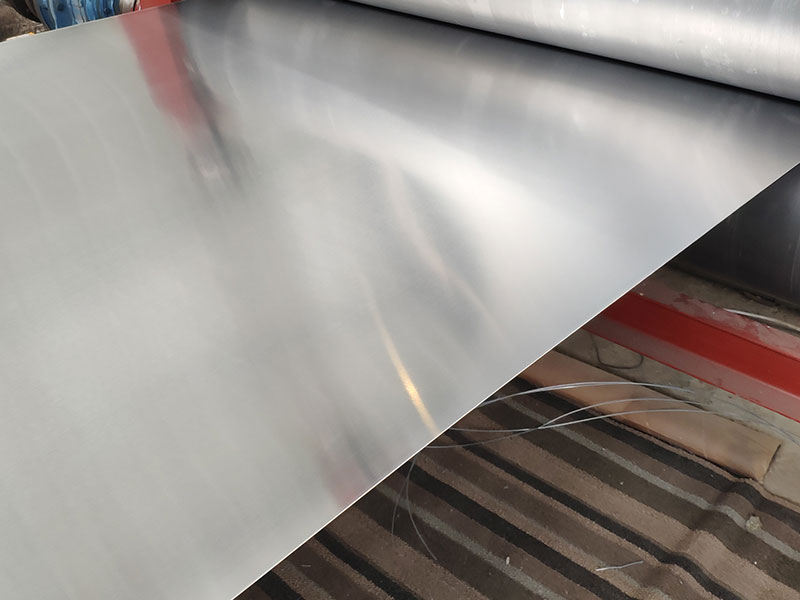

Beyond the technical aspects, I find the pursuit of longer run lengths deeply fascinating from a cost-efficiency perspective. It directly translates to reduced plate changes, decreased downtime on the press, and ultimately, lower production costs for our clients. However, this efficiency shouldn't come at the expense of quality. We're constantly evaluating new plate materials and processing techniques to improve both run length and image fidelity. This balancing act, pushing the boundaries of what's possible with aluminium CTP plates, is what makes this work so engaging. The constant drive for improvement, fueled by both technical innovation and collaborative problem-solving, is what defines our team's approach to delivering superior long-run positive thermal CTP plates.

The Significance of Long Run Length

At the heart of Positive Thermal CTP Plates' appeal lies their characteristic Long Run Length. The term refers to the plate's ability to sustain a significant number of impressions before the quality begins to deteriorate. While traditional plates can fall short of delivering outstanding quality after several thousands of impressions, Positive Thermal CTP Plates can endure an incredible Infinitum—maintaining tonal fidelity and sharp resolution even after substantial runs.

This characteristic is fundamental in shifting the scale of productivity in the print industry. With diminishing downtime and smaller plate replacement needs, operational efficiency reaches new heights. An attribute like this particularly benefits large-scale print operations, where quality and consistency in each impression substantially influence customer loyalty and value.

Applications That Benefit from Positive Thermal CTP Plates

The applications of Positive Thermal CTP Plates are as diverse as they are plentiful. For commercial printers, this technology intertwines reliability and image precision. Whether producing magazines, newspapers, packaging, or labels, printers benefit from enhanced press speeds concurrent with compelling reproduction quality.

Moreover, this technology finds utility beyond standard commercial uses. Specialty print businesses focus on personalized invitations or photo books; the CTP plates encapsulate the detail involved in intricate designs, obtaining the high definition required by upscale offerings. As the demand for vivid artwork in print applications grows, so does the necessity for high-fidelity CTP plates, making this product more invaluable than ever.

Technical Insights

Positive Thermal CTP Plates stem from advancements in both chemical and coating technologies. Recent improvements to the photopolymer layers provide greater sensitivity to thermal exposure, enabling the use of laser technologies to create finer detail and depth in mapping images. This detail is essential for brand awareness and recognition, especially in highly competitive fields where first impressions can retain clients longterm.

Additionally, the plate processing solutions are becoming increasingly eco-friendly, aided by the rise in green consciousness within the industry. Lower waste production combined with reduced energy consumption during thermal processing has compelled many businesses to switch to Positive Thermal CTP Plates not only for performance yet also for environmental stewardship.

https://www.aluminumplate.net/a/positive-thermal-ctp-plate-with-long-run-length.html