UV Ink Resisted Thermal CTP Plate

In the modern printing landscape, efficiency, quality, and consistency are paramount. Enter the UV ink resisted thermal CTP plate—an innovative solution that is transforming how print media is produced and maintained. Combining advanced technology with practical applications, these plates are not just a trend; they are a necessary evolution for print professionals searching for durability and precision.

the Basics: How Do They Work?

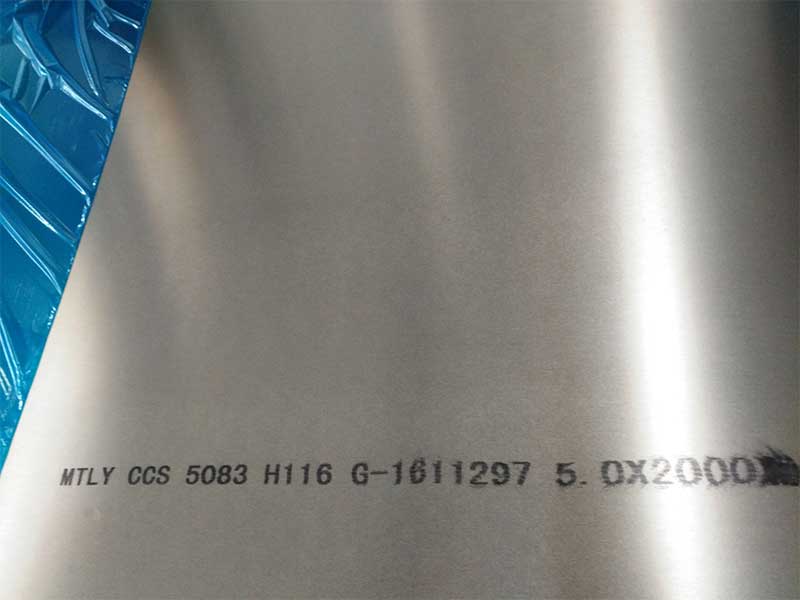

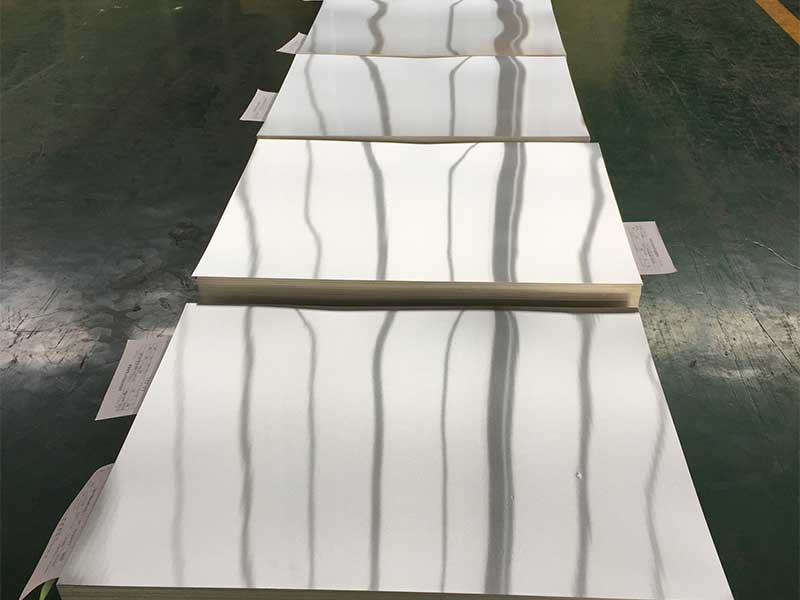

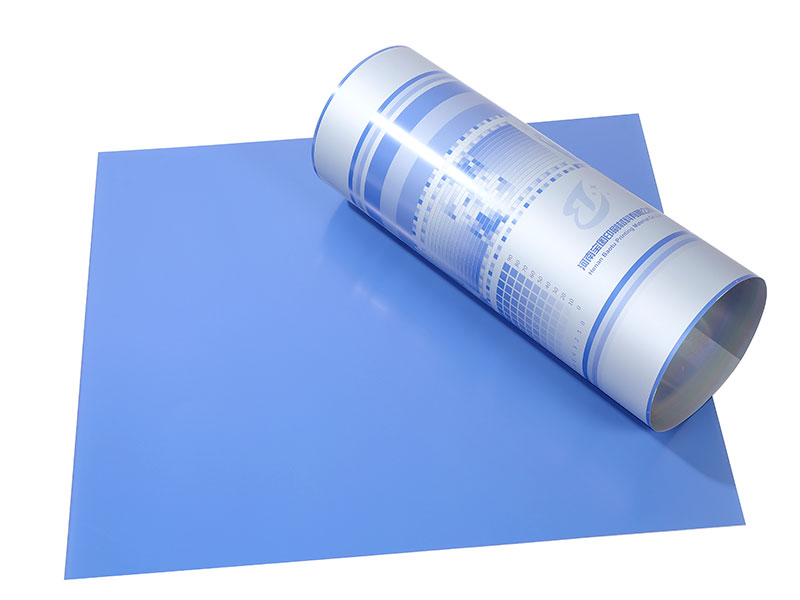

A UV ink resisted thermal CTP (Computer to Plate) plate begins its life as a durable substrate. The substrate is coated with a photosensitive emulsion that reacts to infrared (thermal) laser light during the imaging process. Below are functionalities that define this remarkable product:

-

High Sensitivity to UV Light: What sets UV ink resisted thermal plates apart is their ability to effectively resist UV inks after imaging. As the inked plate is exposed to UV light, it alters the physical properties of the coating in the exposed areas, enabling precise print application without compromising on color depth.

-

Thermal Sensitivity: The thermal technology utilized in these plates allows for easier, faster processing compared to traditional methods. Shortening the time from design to print enhances operational efficiency and cuts down production costs.

Technical Advantages That Make a Difference

-

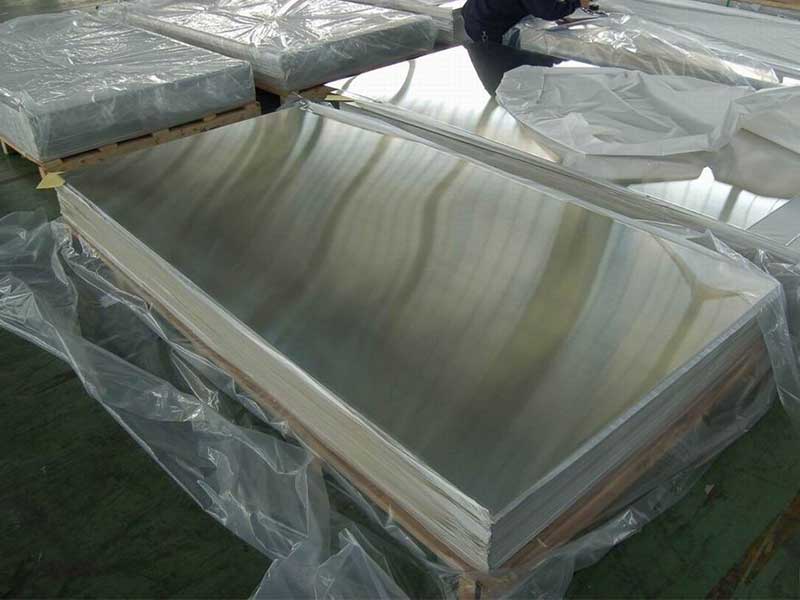

Enhanced Durability: The coating's resistance to UV inks minimizes wear and tear, leading to longer run lengths and reduced plate remakes. This durability means less downtime and higher profitability for printing companies.

-

Superior Print Quality: These plates facilitate higher image quality with excellent tonal range. The precision achieved ensures that color vibrant hues are well-represented in every printed piece. Suitable for high-grade publications, packaging industries, and specialty printing, their utility is unparalleled.

-

Eco-friendly Attributes: With rising awareness around sustainability, UV ink resisted thermal CTP plates often utilize eco-friendly manufacturing processes. They significantly reduce solvents, thus being kinder to the planet while still achieving the high-quality output needed in the commercial print market.

Unique Applications in the Print Industry

The seamless blend of technology and function translates not just into enhanced print quality, but also opens the door to varied applications. Here’s how these plates are best utilized across different printing sectors:

-

Packaging: The resilience of these plates makes a significant impact on packaging prints, where high durability and color accuracy are critical. Manufacturers can enjoy longer plate life and better graphics - essential in the packaging solutions market.

-

Commercial Printing: For brochures, magazines, and advertisements, where color integrity is pivotal, UV ink resisted thermal plates provide trustworthy results. The immediacy in reproduction holds more value for brands looking to deliver impactful perspectives to their consumers.

-

Special Features: Custom projects that require vivid colors or intricate designs benefit extensively from the high fidelity offered by these plates, making them ideal for specialized printing services including stop motion illustrations and art poster prints.

https://www.aluminumplate.net/a/uv-ink-resisted-thermal-ctp-plate.html