Ctp thermal UV ctp offset printing plates

CTP Thermal UV CTP Offset Printing Plates: Revolutionizing Print Quality and Efficiency

In the fast-paced world of printing, efficiency and quality are paramount. Enter CTP (Computer-to-Plate) Thermal UV offset printing plates—an innovation that is changing the landscape of print production.

Working with thermal UV CTP plates for offset printing has highlighted the crucial interplay between plate processing parameters and final print quality. We've found that seemingly minor variations in laser power, exposure time, and developer chemistry can dramatically impact the plate's resolution, dot gain, and overall print stability. For instance, insufficient laser power often leads to weak image areas, resulting in thin lines breaking or halftones appearing muddy. Conversely, excessive laser power can cause unwanted image expansion and dot gain, negatively affecting sharpness and detail, particularly in fine text or small graphics. Careful calibration and consistent monitoring of these parameters are paramount to maintaining consistent plate quality and minimizing waste, especially considering the cost of the aluminium substrate and the consumables involved.

Beyond the technical parameters, optimizing the workflow around the thermal UV CTP process is equally crucial for productivity. We've implemented a system of stringent quality control checks at each stage, from plate imaging and processing to final mounting on the press. This includes regular cleaning of the processing equipment to prevent contamination that can lead to plate defects. Furthermore, the plate's sensitivity to environmental factors like temperature and humidity is critical. Fluctuations in these factors can affect the development process and the plate's longevity on press, leading to potential press downtime and wasted plates. Implementing robust environmental control in the plate-making area significantly improves process consistency and reduces costly errors.

CTP Technology

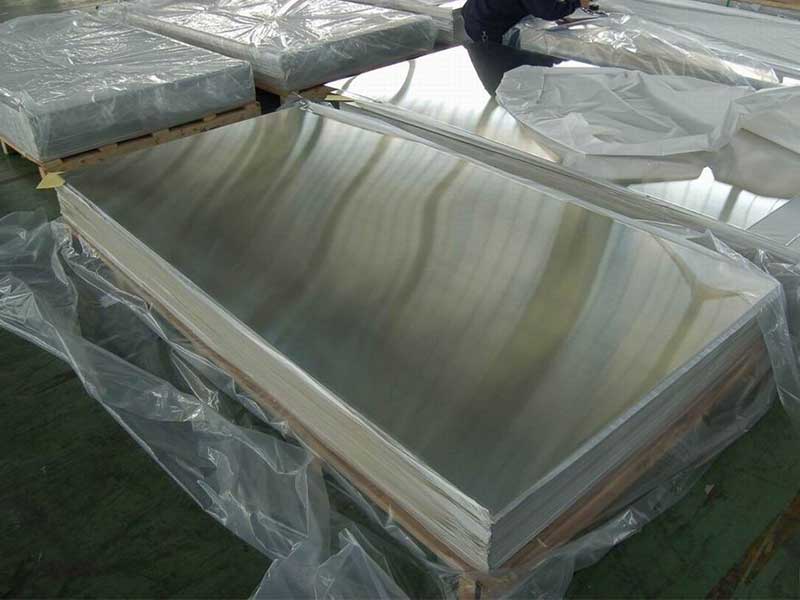

At the heart of CTP technology lies its ability to seamlessly convert digital images into printing plates without the need for traditional film-based processes. In thermal CTP, specially coated aluminum plates are exposed to laser light, which precisely transfers the desired imagery onto the plate surface. These plates are processed with a specific chemistry that develops only the areas exposed to the laser beam, ensuring optimal quality in printed output. The unique advantage of thermal plates comes to the forefront when combined with UV (ultraviolet) technologies.

The Distinct Features of Thermal UV CTP Plates

-

Superior Print Quality: Thermal UV CTP plates are engineered to deliver outstanding print resolution, allowing for sharp and high-contrast images. The positioning of the laser in the CTP process plays a crucial role, ensuring details remain vibrant and colors pop even in the most meticulous designs.

-

Enhanced Durability: Unlike conventional plates, Thermal UV plates boast improved durability because of their unique processing methods that resist wear and tear. They're designed to withstand the rigors of the printing process—low on water and ink consumption, which results in less waste.

-

Drying Time Efficiency: One standout advantage of UV technology is its quick-drying capabilities. UV inks cure instantly when exposed to UV light, allowing for faster production speeds. This feature caters to businesses that thrive on quick turnaround times, significantly enhancing workflow and increasing productivity.

-

Eco-Friendly Option: With the push toward sustainability in recent years, the eco-conscious nature of Thermal UV CTP offset printing plates is noteworthy. They produce fewer VOCs (volatile organic compounds), reducing their environmental footprint. Additionally, their longevity translates to less frequent plate replacements, further aligning with green objectives.

-

Versatility: These plates are suitable for a wide array of substrates— from coated paper and uncoated paper to synthetic and specialty materials, voiding the need for multiple plates for varied print jobs. This versatility also eliminates the complications associated with using different inks.

Applications in Diverse Industries

The real charm of Thermal UV CTP offset printing plates can be witnessed across various sectors:

-

Commercial Printing: Used for high-volume applications such as brochures, flyers, and catalogs, these plates effectively streamline the production process while maintaining quality. Their reliability makes them a go-to choice for printers seeking to balance efficiency with top-tier output.

-

Packaging: The food, beverage, and cosmetics industries demand vibrant, well-detailed packaging to capture consumer attention. Thermal UV plates help deliver graphics that command shelf presence while ensuring the print quality adheres to stringent safety standards.

-

Fine Art Printing: Limited edition prints and reproductions thrive on quality and precision, and CTP plates allow for the intricate detail that artists and photographers seek, preserving shades, colors, and textures remarkably well.

-

Labels and Tags: Industries centered on labeling—like health and beauty or personal care—benefit wholeheartedly from specialists in CTP. The quick turnaround combined with the ability to handle intricate designs makes CTP Thermal UV an ideal option in group supply chains.

-

Textiles and Fashion: The advent of fabric printing opens a realm where visuals can be transferred directly onto fabric for innovative designs. Each print on textiles can be executed effortlessly, ensuring vibrant colors and patterns.

https://www.aluminumplate.net/a/ctp-thermal-uv-ctp-offset-printing-plates.html