The positive ps plate for 4 color offset printing machine offset ctp ctcp printing plates

Positive PS Plate for 4-Color Offset Printing Machine: Elevating Offset CTP Printing Quality

In the realm of modern offset printing, the integration of Computer-to-Plate (CTP) technology has revolutionized the pre-press process, enabling sharper, faster, and more economical printing workflows. Among the essential components driving this innovation is the Positive Photo-Sensitive (PS) Plate specifically designed for 4-color offset printing machines. its functions, technical details, and practical applications unveils why it serves as the cornerstone of high-quality offset CTP printing plates (CTCP).

What is a Positive PS Plate in Offset CTP Printing?

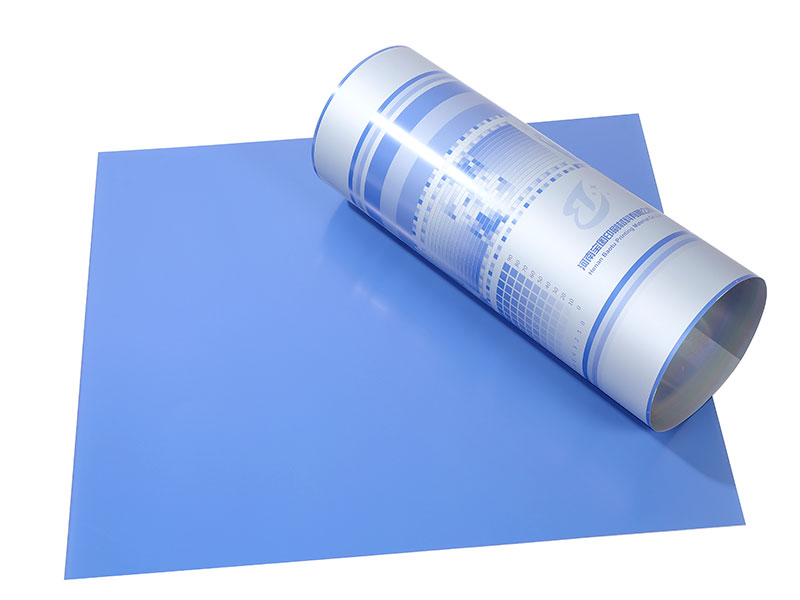

A Positive PS Plate is a type of printing plate coated with a light-sensitive emulsion that hardens when exposed to UV or laser light. “Positive Image” means the exposed areas become the printing areas on the final plate. This contrasts with a negative PS plate, where the unexposed regions constitute the print image.

For 4-color offset printing—commonly Cyan, Magenta, Yellow, and Black (CMYK)—precision and fidelity of each plate greatly impact color consistency and overall image quality. Positive PS plates, tailored for this process, ensure outstanding detail and resolution.

Technical Details and Functional Advantages

1. Superior Sensitivity and Imaging Quality Positive PS plates are engineered for superior photopolymer coatings that directly affect their light sensitivity and endurance during image processing. They respond excellently to laser diodes commonly used in CTP machines for image writing. The laser exposure precisely hardens the emulsion on the image areas. Post-processing, the plate is developed in a specially formulated alkaline developer, washing away unhardened areas to create raised printing regions.

2. Fine Grain Emulsion and High Resolution Using advanced micrograined or nanograin diazo or photopolymer agents, the plates achieve exquisite detail at microscopic levels. This finely structured emulsion supports very fine dots for four-color printing halftones, allowing smoother gradients and sharper text reproduction—critical in 4-color multitone printing requiring high dot fidelity.

3. Excellent Run Length and Durability Positive PS plates boast longer run lengths, often supporting more than 100,000 impressions before degradation in quality appears. Their durability ensures consistent color reproduction of CMYK plates, vital in commercial production runs with stringent turnaround demands.

4. Chemical and Mechanical Resistance The plates resist abrasion and chemical attacks during printing. The robust coating withstands repeated plate handling and press scraping yet maintains coating integrity, enabling stable impressions throughout extended print jobs.

Applications in 4-Color Offset Printing

Commercial Printing Used widely in magazines, brochures, and catalogs requiring crisp CMYK reproduction, positive PS plates enable vivid, precise multi-color images—protecting color fidelity when printing high-volume runs with complex graphic designs.

Packaging Materials Four-color packaging printing depends on perfect color registration between inks, requiring CTP plates capable of reliable exposure and development. Positive PS plates preserve fine details in logos and fine texts on varied substrates.

Newspaper and Periodicals Thanks to faster processing times with CTP, combined with high-resolution positive PS plates, publishers can achieve quick turnaround with sharp photo and image prints for color newspapers and scientific journals.

Fine Art and Photo Reproductions Artists and print professionals value positive PS plates for offset art printing, where tonal transitions and accurate color translation hinge on plate plate sensitivity and image integrity after plate processing.

Integrating Positive PS Plates in Offset CTP Workflows

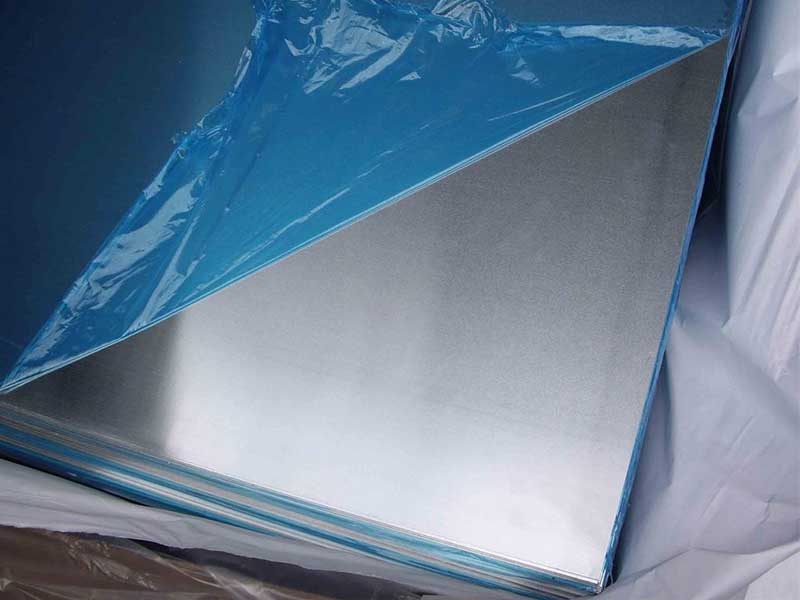

Working in sync with 4-color offset presses, positive PS plates must align perfectly with CTP systems and automatic processors. Proper storage before exposure—shielding from light and moisture pairing with optimal developing conditions—guarantee that sensitivity and plate quality remain intact.

Ultimately, positive PS printing plates extend the spectral limits of multicolor offset printing by merging cutting-edge photo-polymer chemistry with precise laser writing in modern CTP setups. Their capacity to deliver robust, high-fidelity printing images supports commercial printers striving for fast, reliable, and cost-effective 4-color operations. The positive PS plate's continual innovation continues tu drive quality enhancement in the future of multicolor offset printing.