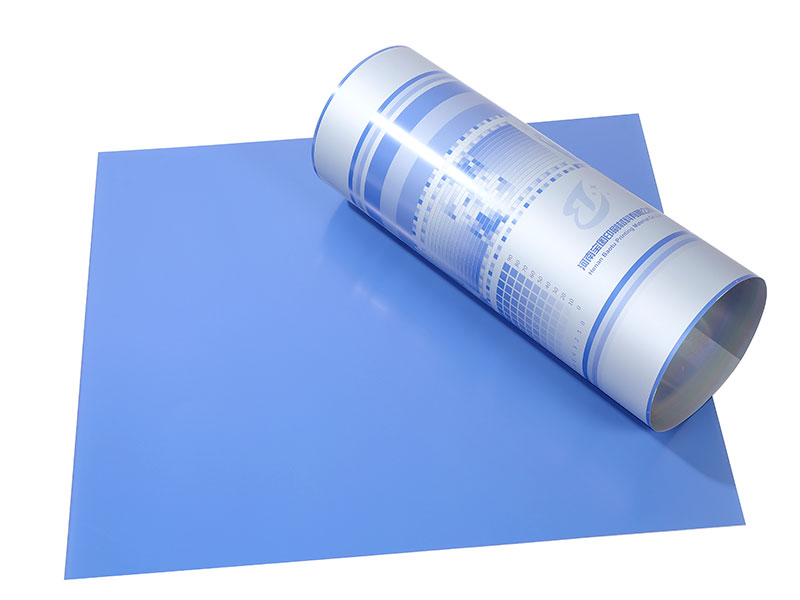

Double Layer Thermal size CTP Printing Plate for offset Printing Machine

In the ever-evolving world of printing technology, choosing the right materials can drastically impact your offset printing business's efficiency and quality. One innovation that stands out is Double Layer Thermal CTP (Computer-to-Plate) printing plates. As an essential component of the offset printing process, these plates enable printers to achieve superior print quality and optimize their production workflows.

What Are Double Layer Thermal CTP Printing Plates?

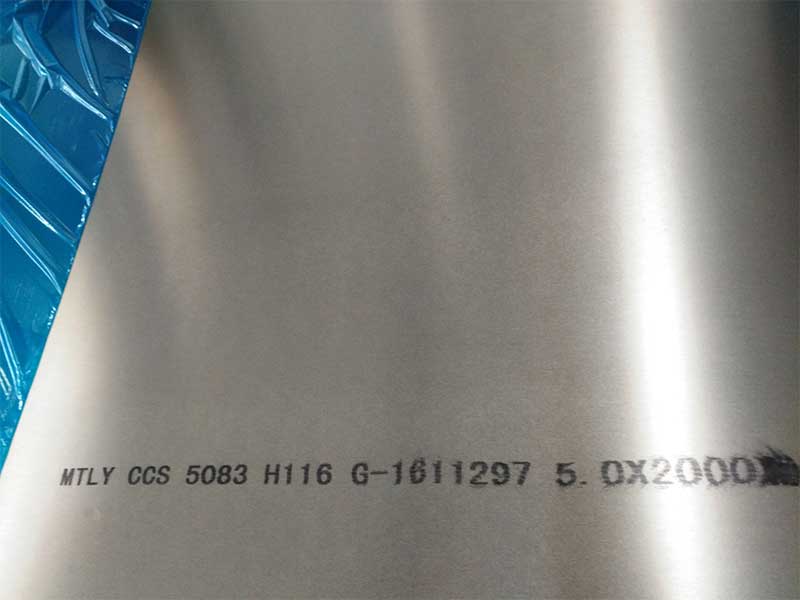

Double Layer Thermal CTP printing plates consist of a unique two-layer structure that thrives in various print applications. Unlike traditional single-layer plates, the double layer design employs advanced thermal sensitivity and ensures enhanced durability, accuracy, and fast processing. This feature is vital for modern offset printing operations that demand detail and efficiency.

Benefits of Using Double Layer Thermal CTP Printing Plates

-

Exceptional Print Quality: One of the most remarkable features of Double Layer Thermal CTP plates is their ability to deliver exceptional image resolution and reproduction. They create sharper, clearer, and cleaner prints, allowing you to enhance the overall quality of your print jobs. High-quality resolutions reduce imperfections such as blurring or ghosting.

-

Faster Processing: With the double-layer technology, the response time in the imaging process is significantly improved compared to standard plates. This means that you can achieve final images faster, drastically reducing your production cycle time, which is essential in today's fast-paced printing environment.

-

Cost-Effectiveness: Investing in Double Layer Thermal CTP printing plates means optimizing your operational costs. Through reduced plate processing times, decreased plate wear, and lower ink consumption due to higher efficiency, these plates prove to be a wise long-term investment for your business.

-

Enhanced Durability: These plates are designed to withstand the rigors of multiple print runs, showing superior performance even in challenging conditions. Their robust structure and a special coating help ensure that they dispatch quality prints run after run, maintaining your production consistency.

-

Eco-Friendly Option: Many modern double layer thermal plates are made from environmentally responsible materials and are designed to minimize waste. Retaining a focus on sustainability can give your printing business an added advantage and appeal to eco-conscious customers.

Integrating Double Layer Thermal CTP Plates into Your Workflow

Integrating Double Layer Thermal CTP printing plates into your offset printing workflow is both a straightforward and intelligent decision. If you're transitioning from traditional printing methods to modern CTP technologies, it’s essential to work with a reliable supplier who can provide expert guidance throughout this shift.

Breaking it down:

- Consultation: Discuss your specific needs with an aluminum CTP plate supplier to identify the best fit for your printing machinery.

- Training: Ensure your team is well-trained in operating the new CTP systems to maximize efficiency.

- Testing & Adjustments: As with any new system, take the time to run tests and make adjustments to your inks and settings for optimum results in your printed products.