Metal keyring Mirror Phone Case Printing 0.4 0.5 0.7mm Aluminum Sheets

In the age of personalization, consumers are searching for unique and customized items that reflect their identity and style. One of the vibrant miniatures of this trend is the metal keyring mirror phone case, a combination of convenience, style, and artistry. Central to the effectiveness of these products is the quality of the aluminum sheets utilized during production, particularly those with varying thicknesses of 0.4mm, 0.5mm, and 0.7mm. Each thickness brings unique aesthetics and functional benefits, paving the way for enhanced printing possibilities.

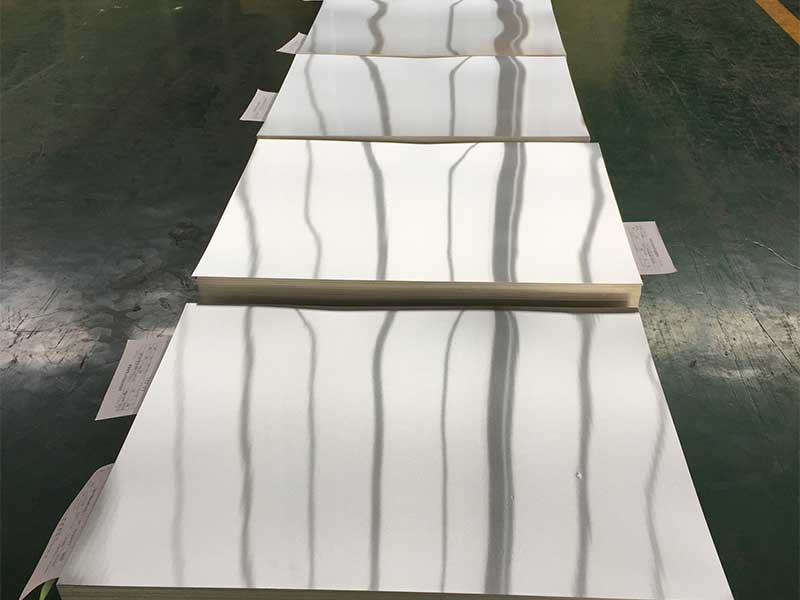

Aluminum Sheet Thickness

When selecting the right aluminum sheet for phone case printing, thickness is paramount. It influences both the durability of the final product and quality of the print.

- 0.4mm Aluminum Sheets:

- Lightweight Versatility: At a mere 0.4mm, this thickness is ideal for users who prefer lightweight accessories. This is a particularly favorable option for people on the move, providing flexibility without weighing down their bags.

- Printing Precision: The reduced thickness makes it easier for manufacturers to achieve high-resolution prints. Designs maintain sharpness and clarity; ideal for those tricky graphics that require immaculate details.

- 0.5mm Aluminum Sheets:

- Moderated Durability: The 0.5mm aluminum balances weight and durability crisply. While it remains a lightweight option, it offers several layers of natural protection against bends and scratches. It enhances overall product longevity, ensuring your personalized phone case stands the test of time.

- Rich Print Resolution: This thickness excellently filters printer capabilities to ensure smooth gradient colors, especially in large, epically designed scenarios against mirror-like surfaces to reflect artistic sentiments effectively.

- 0.7mm Aluminum Sheets:

- Enhanced Protection: By providing increased sturdiness, the 0.7mm thickness defends a phone case from bumps, drops, and yet again preserves charm—after all, metallic cases should look striking as well as provide charge. This is especially beneficial for families with kids or those engaged in active outdoor lifestyles.

- Adaptable Design Capacity: Investing in 0.7mm Aluminum Sheets opens the door to an expansive realm of creative endeavors. Utilizing advanced sublimation techniques at this mass, the mirrors invite vibrant colors and intricate graphics that tantalize the eyes of onlookers.

The Printing Process

Engaging with quality aluminum, regardless of thickness, necessitates using the right printing method. Techniques like sublimation and direct-to-metal printing are modern choices essential for any metal keyring mirror phone case.

-

Dye Sublimation: For aesthetics that pop—converting solid dye into gas under heat is paramount. The vibrance and fusion the machine crafts locks interconnected patterns naturally to a textured surface, breeding invulnerability against fade over time.

-

UV Printing: Leveraging low-energy waves ensures encapsulation around print displays clarity and durability—a lustrous match married with any phone bid invites a satisfying tangible grip and a visually enticing finish, meant to intrigue everyone.