Printing Plate Aluminum Plate Positive CTP Plate

The evolution of printing technology has ushered in a new era of precision and efficiency, significantly altering how businesses approach their printing needs. One of the pivotal innovations in this transformation is the use of positive Computer-to-Plate (CTP) technology, specifically Aluminium CTP Plates. These plates are at the forefront of ensuring clarity, accuracy, and superior quality in printed material, from magazines to large-format signage.

The Functionality of Aluminium Positive CTP Plates

At its core, a Aluminium CTP Plate operates as a technology that converts digital files into physical printing plates, streamlining the pre-press phase of production. Unlike traditional methods where cumbersome processes resulted in a loss of detail, the positive CTP approach allows for high-definition imaging. Here’s how it works:

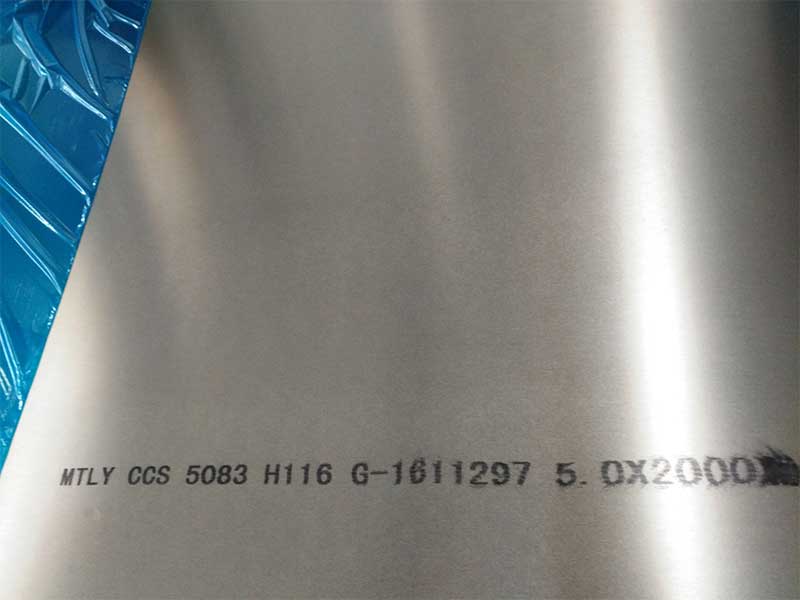

Working with Aluminum CTP plates daily reveals a fascinating interplay between material science and print quality. The positive nature of our CTP plates, where the image areas are raised, presents unique challenges compared to negative plates. We've found that the grain size and alloy composition of the aluminum substrate significantly impacts the plate's lifespan and resolution capabilities. Finer grain structures generally yield sharper, more detailed prints, but can be more susceptible to scratching during processing. Furthermore, optimizing the anodization process is critical; too thin a layer compromises durability, leading to premature wear and poor image fidelity, while too thick a layer can hinder plate development and reduce sensitivity to the laser. these subtle nuances is to consistently producing high-quality plates.

Beyond the material itself, the processing parameters are equally crucial. Laser power, exposure times, and the chemistry used in the developing and post-processing stages all influence the final plate quality. We’ve seen firsthand how inconsistencies in any of these steps can lead to issues such as pinholes, uneven ink transfer, or ghosting on the final print. Our troubleshooting often involves meticulously reviewing each stage of the production process, from the initial plate preparation to the final quality inspection. This holistic approach, combined with regular maintenance of our processing equipment, ensures we consistently deliver high-quality Aluminium CTP Plates that meet our clients' demanding specifications.

-

Digital Imaging: The process begins with a high-resolution digital file. When it’s time to print, this file is sent directly to a CTP system, which utilizes laser technology to ‘engrave’ the image onto the surface of the aluminium plate.

-

Exposure Process: The laser precisely ablates the non-image areas (the parts that won’t be printed), while preserving the image areas. This direct-to-plate method eliminates the need for creating a film positive and provides consistent imaging every time, which is paramount for large print runs.

-

Chemical Processing: Once imaging is complete, the plate is subjected to a chemical process that further enhances the image area and prepares it for revelation. This critical step ensures the print quality meets high professional standards.

-

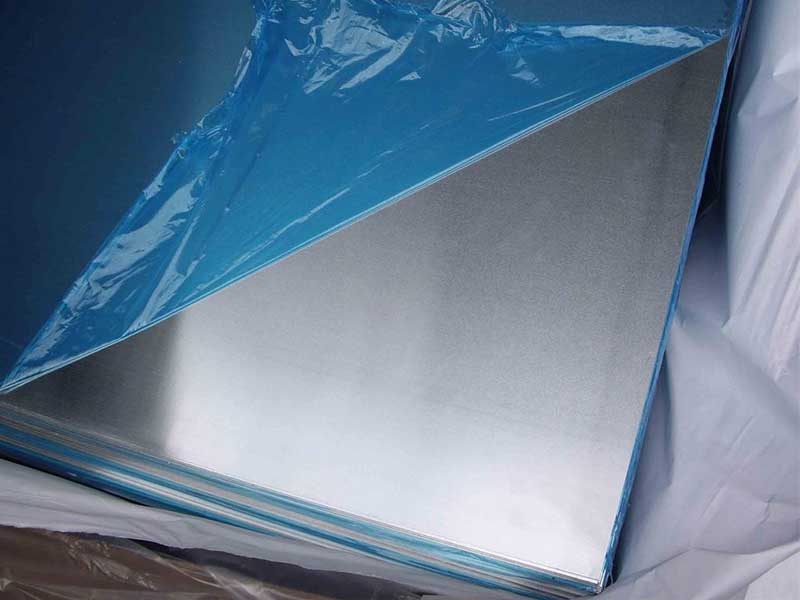

Ready for Printing: After processing, the Aluminium CTP Plate is mounted onto the printing press, ready to deliver exceptional print outcomes, showcasing vibrant colors, consistent tonality, and sharp details.

Applications Across Industries

The versatility of Aluminium Positive CTP Plates makes them indispensable across various sectors. Here are some applications:

-

Commercial Printing: From brochures to marketing materials, these plates ensure high-resolution and sharp graphics, reinforcing brand messaging.

-

Packaging: In the competitive packaging market, where visual appeal is paramount, the precision of Aluminium CTP Plates allows product packaging companies to create eye-catching designs that undoubtedly attract consumers.

-

Textile Printing: Whether for fashion or home décor, the quality of print units heavily relies on the façade delivered by CTP plates. The ability to produce intricate designs in vibrant colors is a game changer for textile manufacturers.

-

Art Reproduction: Artists and photographers use CTP technology to reproduce fine art with an accuracy that captures the intended details and textures faithfully.

Unique Advantages of Aluminium CTP Plates

In an industry rife with printing options, Aluminium CTP Plates is know with their unique advantages:

-

Eco-friendliness: Many aluminium plates can be processed without harmful chemicals, making them attractive for environmentally conscious businesses.

-

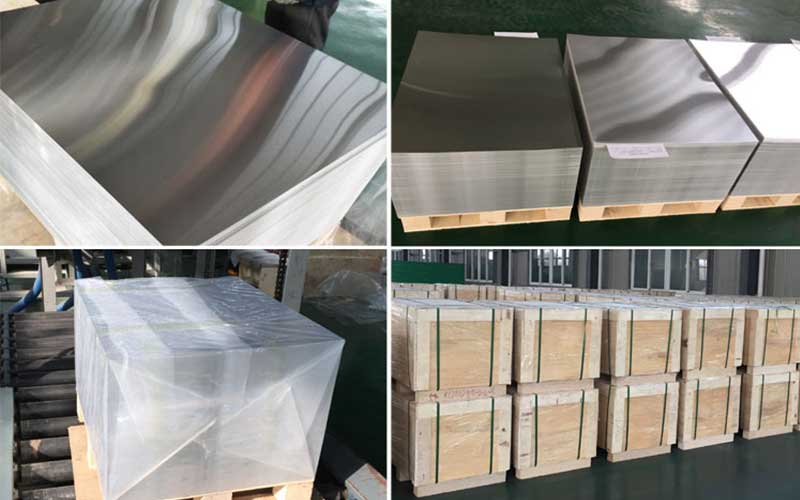

Cost-Efficiency: Reducing the number of wasted prints and minimizing labor in pre-press processes equate to lower costs over time, alongside the long-lasting materials contributing to durability.

-

Quality Consistency: Leveraging advanced imaging technology, these plates consistently deliver high-quality results, alleviating issues of variability that often accompany traditional plate methods.

-

Rapid Turnaround: Fast-moving industries benefit from quicker print turnarounds, and offset registration is finely tuned, assuring not just speed but also efficiency and accuracy.

https://www.aluminumplate.net/a/printing-plate-aluminum-plate-positive-ctp-plate.html