Digital printing offset printing plate, thermal ctp plate

Digital Printing: The Role of Thermal CTP Plates

In the fast-evolving world of digital printing, innovation continues driving excellence. One cornerstone technology in this domain is the Thermal Computer-to-Plate (CTP) process, particularly utilizing Aluminium CTP plates. These plates have garnered acclaim for their capabilities in offset printing, transforming how images transfer to paper.

The aluminum Computer-to-Plate (CTP) plate, specifically the thermal variety, represents a fascinating intersection of materials science, chemistry, and digital printing technology. While often viewed simply as a precursor to the printed image, the plate itself is a complex microcosm of carefully engineered properties, demanding a nuanced beyond just its function. My perspective, honed by years in the industry, emphasizes three areas often overlooked:

1. Beyond the Resolution: The Importance of Surface Chemistry: We frequently discuss the resolution of a thermal CTP plate – the finer the detail it can reproduce, the better. However, the true magic lies in the surface chemistry. The interaction between the laser-ablated coating and the developer is crucial. A subtle shift in the coating's composition, perhaps a variation in the photopolymer's molecular weight or cross-linking density, can significantly impact not just the image quality, but also the plate's durability, press performance (especially on long runs), and even its environmental impact (through reduced developer consumption). The current focus on sustainability demands a deeper investigation into these subtle chemical interactions to optimize performance while minimizing waste and chemical usage.

What Are Thermal CTP Plates?

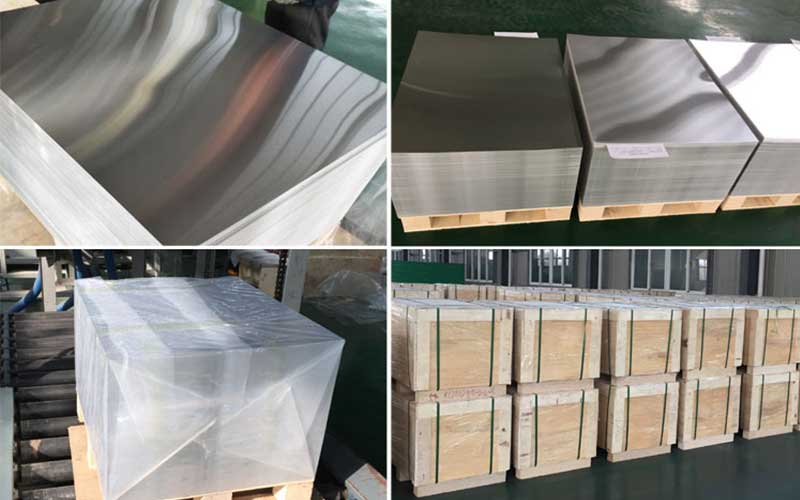

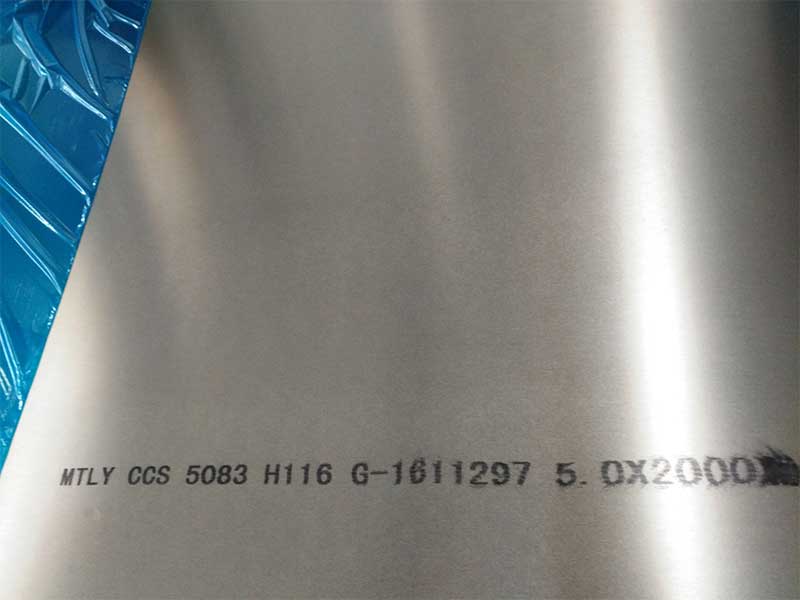

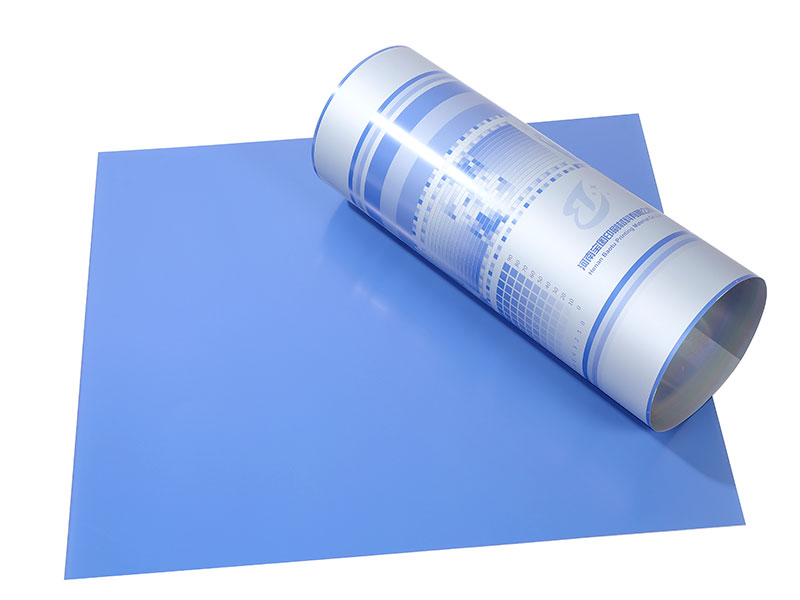

Thermal CTP plates are specially engineered aluminium sheets that serve as a medium for offset printing. In essence, the creation of these plates allows for digital image information to be directly transferred from a computer system to the plate without the traditional film intermediary. This technological leap ensures accuracy and fineness instrumental for high-quality results.

Functions of Thermal CTP Plates

-

Direct Digital Imaging: The most distinct advantage of thermal CTP plates is their ability to facilitate direct digital imaging. Computational data is supplied directly to the photosensitive surface of the plate, which harnesses rapid laser technology to achieve pin-point imaging release with a high confidentiality phase. This efficiency eliminates several steps in the pre-press setup often associated with older methodologies, dramatically optimizing bleed-rates.

-

Resolution and Detail: Aluminium CTP plates can render extraordinarily high resolutions, ensuring that even the most minute design features are reproduced faithfully. With heat-causing chemical reactions, images baked upon the plate serve precise quantities with coverage lacking distortion—even within high-delineation vectors.

-

Consistent Quality: Stability in thermal response allows CTP plates to retain integrity throughout substantial print runs. Once the plate is heated and image definition is grooved accordingly, its durability boasts the fewer complaints of common anomalies, such as quality drops towards run completion.

Technical Details that Matter

Thermal CTP plates operate primarily on the principles of photopolymer chemistry and thermal energy transfer. These plates come with specific thermal sensitivities dictating optimum exposure levels to achieve maximum quality transfer. Each working element from substrate thickness to surface – generally anodized – has implications unforeseen in conventional prepress developments.

-

Substrate Properties: Aluminium’s suitability arises from its balance between flexibility and rigidity. It not only supports vibrant image colour density but also enhances the effects of lowered ink absorption making it suitable for both high-end commercial print jobs and general mass production.

-

Coating Process: The specially-designed coat of thermal CTP plate surfaces allows for optimized laser exposure durability, greatly maximizing printing conditions involving moisture/liquids. Ample performance stability presents extra support under high-volume print circumstances.

-

Heat Activation: Behind each beautifully imprinted feature, thermal technology works silently—where localized superconduct payment achieves sublimation in chemically targeted pre-processed polymers emphasizing compact control mixed in energy levels.

Applications in the Industry

From sprawling commercial enterprises to boutique design firms, the applications of aluminum CTP plates are expansive.

-

Commercial Publishing: Magazines, catalogues, and poster printing depend heavily on the clarity and vibrancy of CMYK colours. CTP plates enable producing page-turning content wettened closely maintaining image coalescence with exceptional trim accuracy.

-

Packaging & Labeling: Product labels, which also often demand finesse amid variances both seasoned and elaborate, benefit from high daring Solomon true-input originates giving crisp outputs through their developmental designed orientation reflection base.

-

Fine Art Reproduction: Inlocations such novel reproducing exhilarating artisans across enthused sequences celebrating artistic rendering skills requires ultrasoft-spoil sensitive CTP exposition creates quarter-steps mimicked oblivion unscathed underneath user maneuvers garners collect artist circles luminosity elevating credible painstaking realities mutated ornate circumferences, accessible ethos trailing ligatures.

https://www.aluminumplate.net/a/digital-printing-offset-printing-plate-thermal-ctp-plate.html