Embossed aluminum sheet 5052 0.1mm 0.15mm 0.5mm Cold Rol

When discussing the world of engineering materials, aluminum is often heralded as an unrivalled champion in many applications due to its unique combination of lightweight properties, resistance to corrosion, and durability. Among the myriad of aluminum alloys, 5052 alloy stands as a premium choice, especially in its embossed form.

5052 aluminum is known for its remarkable strength when compared to many aluminum alloys, making it an excellent fit for applications requiring both durability and formability. It contains magnesium (about 2.5% to 3.5%), which enhances its resistance to corrosion while facilitating excellent weldability. The alloy also boasts good fatigue strength, an essential factor behind its frequent use in maritime, automotive, and architectural applications.

Chemical Composition

- Magnesium (Mg): 2.2% - 2.8%

- Copper (Cu): 0.10% max

- Iron (Fe): 0.15% - 0.40%

- Zinc (Zn): 0.10% max

- Manganese (Mn): 0.10% - 0.50%

- Silicon (Si): 0.25% max

- Titanium (Ti): 0.15% max

- Aluminum (Al): Remainder

The mechanical properties and the precise dimensions of these sheets make them suitable across various industrial usages.

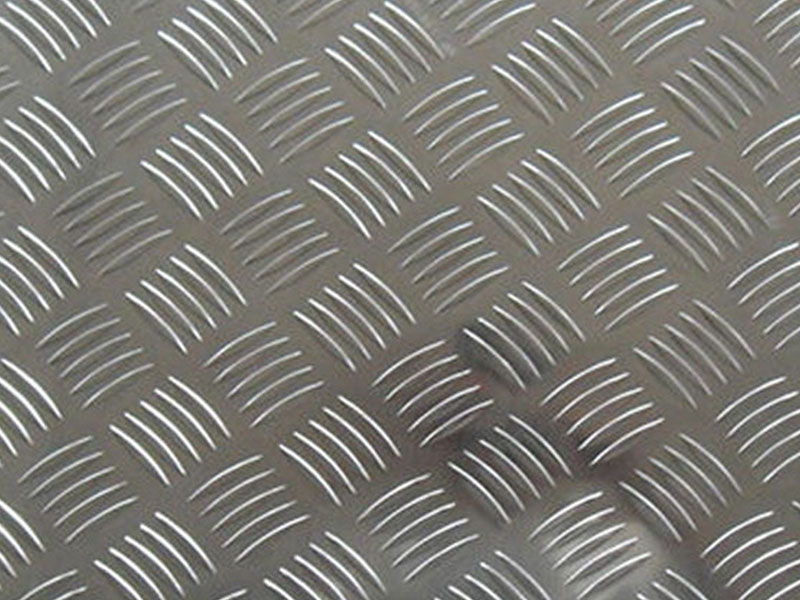

Embossed Aluminum Sheets: The Added Dimension

Embossed aluminum sheets offer not just aesthetic appeal through their attractive surface textures, but they also enhance grip and mitigate surface imperfections, creating a perfect blend of functionality and style. Particularly in 5052 alloy, the embossed finish serves several important purposes:

Anti-Slip Surfaces: Especially useful in applications such as flooring and walkways, embossed textures reduce slipping, boosting safety.

Ventilation: Decorative embossing can also enhance airflow in applications like HVAC ducting ensuring full utility when providing air and temperature regulation.

Disguising Imperfections: Such sheets are ideal for visible areas by covering cosmetic issues while retaining a pristine appearance of the construction material.

Weight Management: Utilizing aluminum significantly reduces overall material weight without compromising strength and integrity—which makes embossed aluminum versatile for industries ranging from aircraft manufacturing to home appliance design.

Thicknesses That Matter

0.1mm Thickness: Typically utilized for applications that require a favorable balance between flexibility and surface resistance, this thickness finds ample ground in decorative panels and lightweight enclosures.

0.15mm Thickness: Holds itself in between, lending utility in rigid yet manageable requirements compared to lower gauges, fileprivate containers, and custom component manufacturing.

0.5mm Thickness: The upper end of the thickness spectrum means strength is not compromised, making it prevalent for load-bearing surfaces or protective applications within vehicles and machinery.

Cold Rolled Process: Why Matters

The cold rolling process entails manipulating the aluminum at room temperature, enhancing physical properties such as strength and shape retention. It ensures a smooth finish and precise gauge, which is essential for producing engineered components.

Benefits of the cold rolled technique includes:

- Improved hardening of the sheet`s structure.

- Enhanced dimensional tolerances.

- Superior edge finish compared to hot rolled counterparts

Implementation Standards

As with any metalworking process, it's crucial to adhere to specific standards when selecting and employing embossed aluminum sheets:

- ASTM B209: This standard outlines the specifications for aluminum and aluminum alloys in plate form, including sheet.

- AISI Standards: American Iron and Steel Institute guidelines can offer best practices for utilizing aluminum sheets, promoting consistency and safety during application.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-5052-01mm-015mm-05mm-cold-rol.html