Mirror Surface Alloy 1070 a O H14

Mirror Surface Alloy 1070 A O H14: The Brilliance Behind the Reflection

In an age where aesthetics marry functionality, the relevance of innovative materials has never been more critical. Among these, the Mirror Surface Alloy 1070 A O H14 stands tall, not just for its reflective capabilities but also for its robust performance in various applications.

1. Mirror Surface Alloy 1070 A O H14

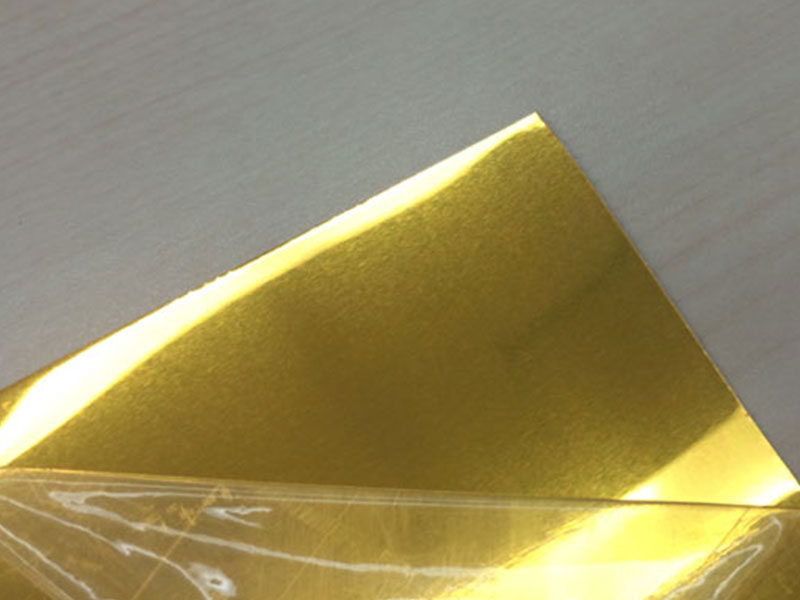

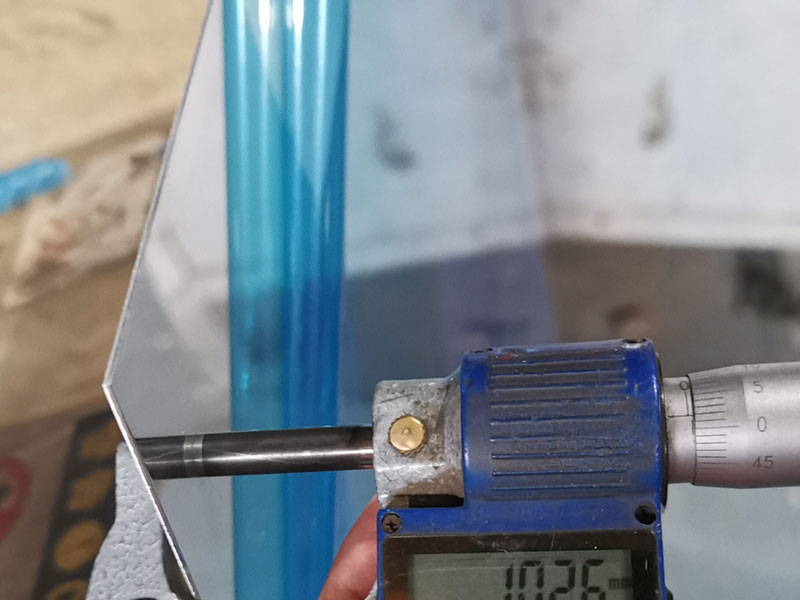

At the core, Aluminum Alloy 1070 boasts an incredibly high purity level, nearing 99.70%. The temper designation “H14” signifies the alloy’s cold working process, enhancing its strength, while M represents specific mechanical properties advantageous in various engineering fields. When this combines with a reflective processing technique, we achieve a mirror-like finish that reflects light drastically more effectively than conventional aluminum sheets.

To summarize:

- Alloy Designation: 1070

- Temper: H14 (Cooling process without an anneal affects strength)

- Surface Finish: Mirror polished

2. Characteristics of Alloy 1070 A O H14

The mirror finish provides increased surface hardness while maintaining the softability required in applications involving bending and manipulation. Unique features include:

- Excellent Corrosion Resistance: Thanks to its high purity, Alloy 1070 exhibits outstanding resistance to corrosion—ideal for specific environments.

- Thermal Conductivity: It provides significant thermal conductivity thus suitable for heat transmission and stability applications.

- Electrical Conductivity: Made where altitude-sensitive situations exist or in moving parts as electrical components.

3. Chemical Properties

chemical properties allows producers and clients to deploy the alloy with confidence. Here’s a chemical properties wheel:| Element | Percentage (%) ||---------------|---------------------|| Aluminum (Al) | 99.70 || Iron (Fe) | 0.25 || Silicon (Si) | 0.10 || Copper (Cu) | 0.05 || Zinc (Zn) | 0.25 || Magnesium (Mg) | 0.05 || Titanium (Ti) | 0.05 || Others | 0.15 |

These modest quantities of unintended trace elements support durability without affecting the primary properties of Aluminum 1070.

4. Implementation Standards

Compliance with international standards ensures quality and dependability in products. To achieve this excellence in fabrication, the following organizations have set crucial guidelines:

The American Society for Testing and Materials (ASTM): Specified standards of finীত material selection, production handling, and final quality inspection are referenced by ASTM B221 for aluminum remember.

International Organization for Standardization (ISO): Under ISO 9001, strict quality assessment outlines govern organizational processes ensuring consistent refinement during manufacturing.

5. Applications of Mirror Surface Alloy 1070 A O H14

The advantages provided by this alloy lend it to a multitude of myriad applications, such as:

Architectural Uses: Ideal for decorative facades or indoors spaces where milieu and design speak volumes.

Reflective Insulation Products: The thermal conductivity character springs it potential in energy-efficient applications.

Consumer Electronics, often used in speakers or the chassis of high-end gadgets, to improve aesthetics and durability.

LED Lighting Fixtures: Utilizing reflective properties enhancing luminescence in narrow interior circumstances.

https://www.aluminumplate.net/a/mirror-surface-alloy-1070-a-o-h14.html