Mirror finish coated aluminum sheet

In a world where aesthetics and functionality collide, mirror finish coated aluminum sheet stands out as one of the leading materials ready for diverse applications. Originally developed for both industrial and artistic pursuits, the elegance and prowess of this aluminum variant has enchanted architects, designers, and manufacturers alike.

The Allure of Reflectivity in Design

At its core, the mirror finish coated aluminum sheet embodies a tantalizing reflection—a hallmark of modern design. This deep reflectivity and superb luster enhance appearance while serving practical operational purposes. Its applications range from high-end clothing racks to ornate architectural facades. This uniqueness stems not only from its surface capabilities but also from the lightweight and strong qualities of aluminum.

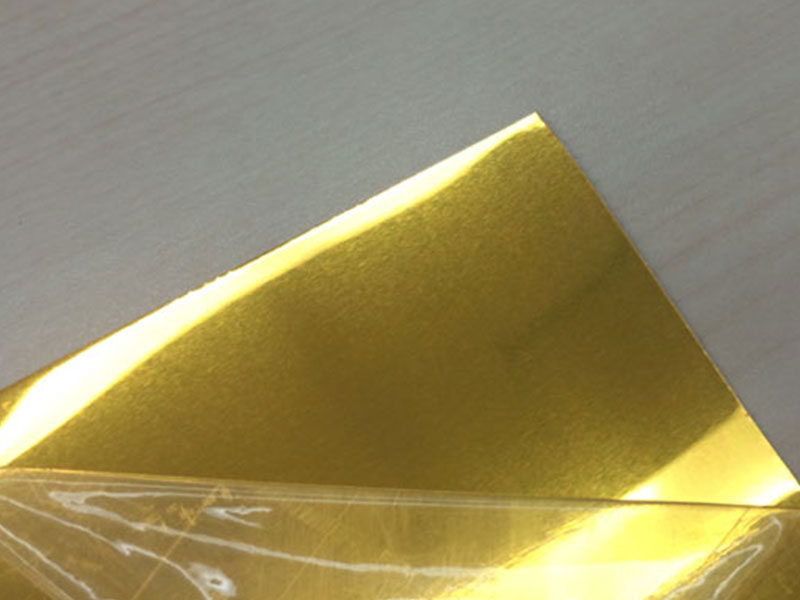

Working with mirror finish coated aluminum sheet is a fascinating blend of art and science. It's not just about the final, gleaming surface; it’s about the intricate process that gets us there. We're dealing with incredibly thin layers of protective coating, often chromium or even more advanced materials, applied with meticulous precision. A tiny imperfection in the base aluminum, a slight variation in coating thickness, or a momentary lapse in temperature control during the process can drastically affect the final reflectivity. It’s a constant challenge to balance the need for a flawless mirror finish with the durability and corrosion resistance required for various applications. The subtle nuances of light reflection – the brilliance, the clarity, even the slight warmth or coolness of the tone – are a source of both pride and ongoing learning.

What truly sets this material apart is its versatility. We see our sheets used everywhere from high-end architectural cladding to precision optical instruments. It's inspiring to know the role we play in creating a product that can transform a building's exterior into a shimmering masterpiece or provide the crucial reflective surface for a scientific instrument. But the process isn't without its quirks; handling these sheets requires extreme care to avoid scratches and fingerprints, and even slight environmental changes can impact the final quality. It's a rewarding job, demanding precision, attention to detail, and a deep of the material's properties – a perfect balance of technical expertise and artistic appreciation.

Technical Makeup of Mirror Finish Coated Aluminum Sheets

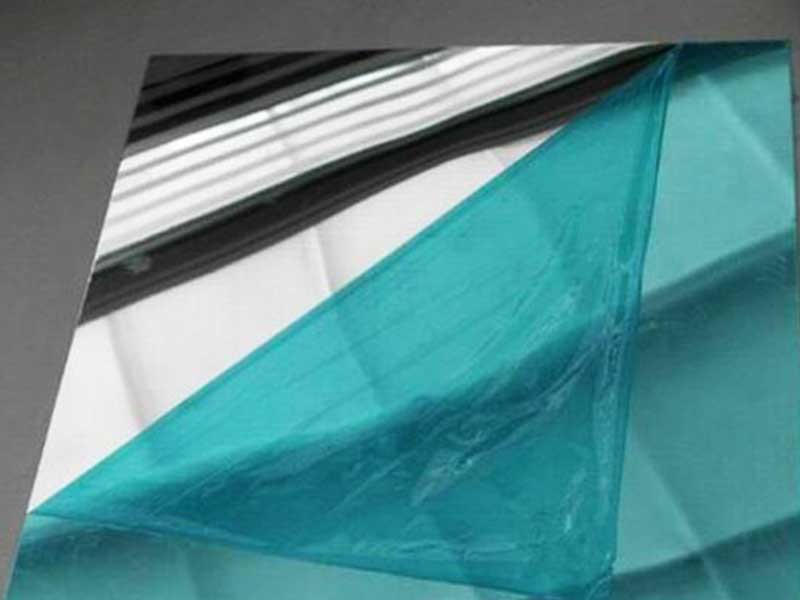

But what truly makes a mirror finish coated aluminum sheet effective? The quality is mainly defined by its surface treatment process, which usually encompasses both anodizing and polishing. Anodization, an electrochemical process, constructs a resilient oxide layer that robustly safeguards the aluminum against corrosion. Coupled with a polishing process, this fabrication yields a sheet that reflects up to 92% of light due to its highly reflective surface.

The brilliance of these sheets allows them to be used efficiently in signage and various aesthetic elements where visibility and reflection are key. Not merely a substance of flair— the technical components ensures longevity and durability when downloaded into masiniembre projects.

Engineered Sustainability

In today’s eco-conscious era, sustainability intricacies further elevate the mirror finish aluminum sheet's profile. Aluminum itself is notably energy-efficient. It can be recycled continuously without degradation of its physical properties. Hence, using this sheet not only adheres to sustainable practices, but reinforces your project's environmental commitments.

Weighing Benefits Against Alternatives

Among various finish options, mirror finish coating provides unparalleled reflection combined with a minimalized weight. Glass is often seen as an intimidating alternative due to its heaviness and vulnerability. In contrast, these aluminum sheets pack a come-hither sensory quality, marrying functionality with a being-there euphoric visualization. Additionally, mirror finish aluminum can withstand temperature variations, contributing to its adaptability in diverse environments.

Practical Applications and Versatility

Several industries and designs may yield startling results through the application of mirror finish aluminum sheets. Their aesthetic appeal makes them limitless for creative ventures—from restaurant interior facades framed in elegant lines to meticulously crafted audiovisual stacks in home theaters surround sound systems. Beyond interior usage, cladding in external architectural ventures allows designers to merge contemporary minimalism with optimal durability.

Looking Towards the Future

As industries evolve, so do the demands surrounding modern aesthetics; mirror finish aluminum sheets naturally step into new frontiers, accommodating that change gracefully. Innovations addressing even finer reflectivity while ensuring stricter control of emission levels are in development. This evolution champions not just the shining features of this brilliant material but forwards sustainability goals in uncertain trajectories.

https://www.aluminumplate.net/a/mirror-finish-coated-aluminum-sheet.html