1050 1070 1060 Mirror Polished Aluminum

The Gleaming Edge of Metal: 1050, 1070, and 1060 Mirror Polished Aluminum

Aluminum has captivated engineers, architects, and designers alike for centuries due to its lightweight nature, durability, and resistance to corrosion. However, in specific applications, the sheen of aluminum can prove to be just as tantalizing as its structural properties. Enter the realm of mirror polished aluminum, with notable grades such as 1050, 1060, and 1070, which not only meet practical criteria but also add an aesthetic touch that elevates any project.

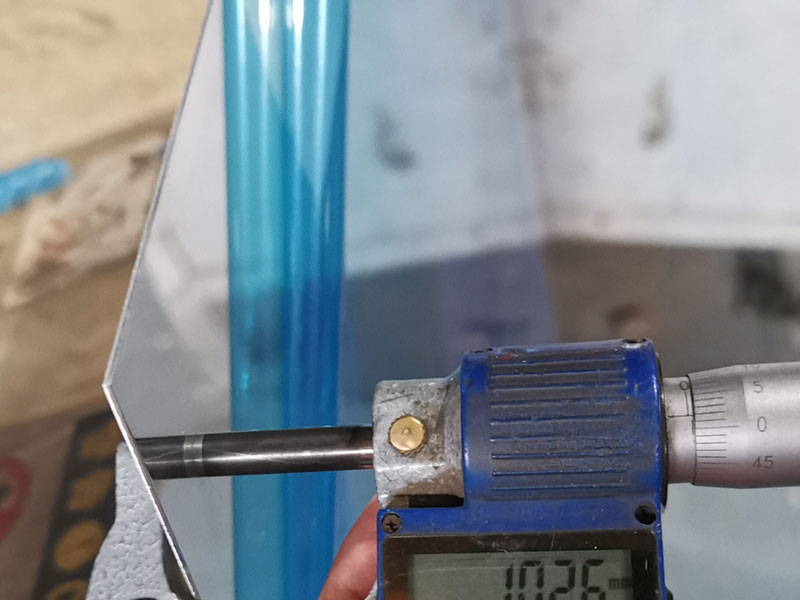

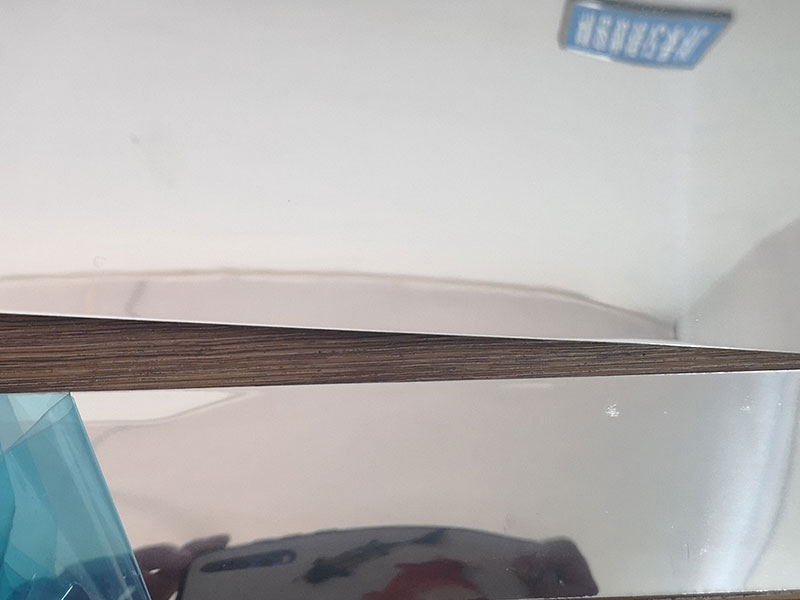

Working with 1050, 1070, and 1060 mirror polished aluminum sheets reveals distinct characteristics impacting their suitability for various applications. 1050, with its high purity, offers exceptional reflectivity and corrosion resistance, making it ideal for demanding applications like reflectors in lighting or decorative elements requiring pristine surfaces. However, its softness can be a drawback, necessitating careful handling during fabrication to avoid scratching or deformation. 1070, possessing slightly higher strength due to a small alloying addition, provides a good balance between workability and durability. It's a popular choice when a slightly more robust material is needed while still maintaining excellent mirror finish capabilities. 1060 sits between the two, offering a compromise in strength and corrosion resistance. We often find that the specific application dictates the alloy choice; a decorative piece might favor the superior reflectivity of 1050, whereas a component requiring more structural integrity might opt for 1070.

Beyond alloy selection, achieving a truly consistent mirror polish across large sheets presents significant challenges. Surface imperfections from the rolling process, even minute ones, can be amplified during polishing, resulting in uneven reflectivity. Our process optimization focuses on careful surface preparation before polishing, utilizing different abrasive grits and polishing compounds to achieve the desired finish. Maintaining consistent polishing parameters like pressure, speed, and compound application is crucial. Furthermore, post-polishing handling is critical; even minor contact can mar

A Reflective Journey Through Grades

- the Grades: The numbers 1050, 1060, and 1070 refer primarily to specific tempers within the aluminum alloy series. Alloys in the 1000 series, which are made up of over 99% aluminum, are known for their high corrosion resistance and excellent workability. Specifically:

- 1050 Aluminum is known for its exceptional conductivity, with minimum 99.5% aluminum content, making it a suitable choice for electrical applications.

- 1060 Aluminum, another high-purity alloy with about 99.6% aluminum, is often used for applications requiring further formability. Its Mama of malleability lends itself well to manufacturing processes.

- 1070 Aluminum, exceeding 99.7% purity, pushes the boundaries slightly, providing enhanced conductivity—a critical factor for sectors like electronics.

- Mirrored Brilliance: The term "mirror polished aluminum" refers to a meticulously started finishing process that elevates the ordinary attributes of these grades. Through mechanical polishing, surface imperfections are eliminated, invoking a captivating reflective quality that almost resembles a looking glass. This glimmer is not merely for show; it transforms functional materials into beautiful works of art.

Features That Make Waves

-

Aesthetic Appeal: The striking surface of mirror polished aluminum not only offers a high degree of reflectivity but also modernizes the appearance of establishments and items alike. Architects and interior designers are drawn to its ability to rejuvenate spaces by reflecting light and curating ambiance.

-

Durability and Maintenance: While it shines brightly, it also is equipped to stand the test of time. The unique properties of these aluminum grades mean less maintenance is required; a simple cleaning process can keep the luster intact, without the need for specialized treatments.

-

Hydrophobic Properties: Due to its mirror-finish, polished aluminum has performance advantages such as reducing the adherence of pollutants and moisture, contributing to its low upkeep.

Applications Across Industries

-

Architectural Marvels: One of the quintessential applications of mirror-polished aluminum is in architecture, where it graces building facades, ceilings, and artistic installations. Its reflective surface not only uplifts the environment but contributes to energy efficiency through reflected light.

-

Electronics: In functionality with a radiant touch, many consumer electronics share housing components made from these aluminum grades. Its high conductivity ensures efficient energy transfer while the aesthetic appeal enhances visual branding.

-

Automotive Components: Lightweight yet aesthetically pleasing vehicles have a myriad of aluminum applications, from trim and badges to alloy wheels, where the mirror finish adds elegance without sacrificing structural integrity.

-

Food and Pharmaceutical Industries: Certain applications in these sectors favor the shiny appeal of mirror polished aluminum for containers and surfaces that require stringent hygienic conditions. The reflective properties facilitate easier inspections for cleanliness and contamination.

https://www.aluminumplate.net/a/1050-1070-1060-mirror-polished-aluminum.html