Color Anodizing Aluminum sheet for Electronics

In the fast-evolving landscape of electronics, the materials utilized not only influence performance but also significantly contribute to device aesthetics and brand identity. Among these materials, color anodizing aluminum sheets have carved out a niche, combining technical prowess with artistic flair—a perfect storm for tech manufacturers seeking both form and function.

What is Color Anodizing?

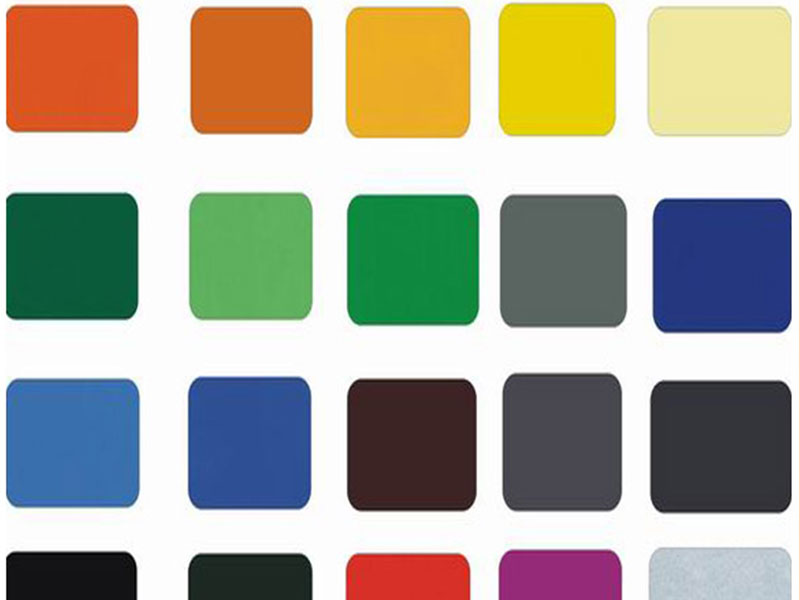

Color anodizing is an electrochemical process that transforms aluminum alloys into a decorative, durable, corrosion-resistant, and anodized finish. Electrolytic coloring can be done prior to or after anodization, resulting in multiple colors that blend seamlessly with the increasingly vibrant electronic designs found in everything from smartphones to intricate circuit boards.

From my perspective on the factory floor, color anodizing aluminum sheet for electronics presents a fascinating blend of aesthetics and practicality. We see a huge demand for consistent, vibrant colors that not only enhance the visual appeal of consumer electronics but also offer crucial protection against corrosion and wear. The tight tolerances required by the electronics industry are a constant challenge – a minor variation in color or anodize thickness can lead to rejection, highlighting the precision needed in our process. I’ve personally witnessed the impact of even tiny adjustments in the anodizing bath chemistry on the final product’s hue and durability, emphasizing the importance of meticulous control and continuous monitoring. We're constantly working to improve our efficiency and reduce waste, particularly in the handling of the chemicals involved in this process.

Beyond the technical aspects, I find it interesting to consider the lifecycle of these sheets. We’re producing a component that will likely end up in a smartphone, laptop, or other device used globally. It's a small part, but a critical one, contributing to the overall quality and longevity of the finished product. Knowing our work plays a role in something that many people will interact with daily is rewarding. There’s a sense of pride in seeing our consistently high-quality anodized aluminum contribute to the sleek, modern designs demanded by the ever-evolving electronics market – and the constant innovation within the electronics industry pushes us to constantly refine our processes and explore new anodizing techniques and

Enhancements in Performance

-

Corrosion Resistance: Aluminum's natural resistance to corrosion is enhanced greatly by color anodizing, creating an even thicker protective oxide layer. This factor is crucial for electronics exposed to changing environmental conditions and operational stress. Consider smartphones, tablets, or laptops—color anodizing guards against imperceptible flaws while ensuring longevity.

-

Heat Dissipation: Efficient thermal management is paramount for electronic devices that generate high levels of heat. The porous structure of anodized aluminum enhances heat dissipation properties due to a larger surface area for heat exchange, ultimately leading to improved device performance and user experience.

-

Durable yet Lightweight: Sculpting devices with an attractive finish often leads manufacturers to compromise on weight. This isn’t the case with color anodized aluminum sheets. Retaining noticeable reductions in weight, they offer intrinsic strength and robustness—ideal for sophisticated devices without mass. For application in drones or electric vehicles, every ounce counts, making them a prime choice for manufacturers.

Aesthetic Value Meets Functionality

Seamlessly merging art and science, color anodizing extends beyond mere protective functions to enhance visual appeal. Utilizing various hue customization, designers can align with branding initiatives while ensuring device recognition amid a crowded market. Digital and mobile devices today prioritize aesthetic integration; hence an embodiment of a distinct color palette through anodizing can traverse designs into recognizable experiences.

Dye Absorption Techniques

-

Structural Coloring: Thanks to nanostructures within anodized aluminum, certain processes result in brilliant colors generated through structural effects, rather than the application of surface dyes. This astonishing property offers remarkable vibrancy—even with light, you can witness chromatic shifts, much like fatigue-resistant designs prominent in automotive applications.

-

Electrolytic Dyes: Alternately, special dyes can be added post-anodization to deepen the color saturation…and options are virtually limitless! Whether it's a subtle matte black or bold crimson flash, manufacturers can tap into branding themes that echo personality, ensuring unmatched product alignment.

The Eco-Friendly Choice

In any industry, embracing sustainable practices is increasingly crucial, translating into core efficiency throughout production cycles without diminishing quality. The anodizing process reuses huge quantities of undyed sulfuric acid, operational costs ultimately driven down while bridging opportunities for reducing environmental impact—showing conscious decisions directly benefit device lifespans and electronic circularity.

Final Thoughts

Color anodizing aluminum sheets is know extensively in the fast-paced electronics industry for multiple compelling reasons—it promises durability that caters to performance, enlivens aesthetics with bold customization options, and leans in on sustainable practices that define the modern approach.

For manufacturers whose missions resonate closely with innovation entwined with sustainability, leveraging color anodizing not only bridges gaps regarding performance needs but entails a beautiful commitment to device-panning that aficionados are bound to appreciate. With brighter horizons markup, the capabilities of color anodizing aluminum are poised for continued advancement within our cherished devices.

Equipping your electronic dream with color anodized aluminum sheets isn't merely packaging; it represents fostering creativity—musicians' ingenuity rubbed shoulders with engineers shunning doubts to best use lightweight yet resilient materials; it's the rather melodic embrace of anodizing. Let your branding illuminate—as we redefine deep-seated ideologies around aesthetics by murmuring vibrant currents rather than jaded fumes. Allow color anodizing as an avenue reverberate, merging technology redraw with precise electrical balance while sparking myriad conversations anew. Purchase unmatched sheets built for svelte beauty altered for why life beckons superior uniqueness—expect no less!

https://www.aluminumplate.net/a/color-anodizing-aluminum-sheet-for-electronics.html