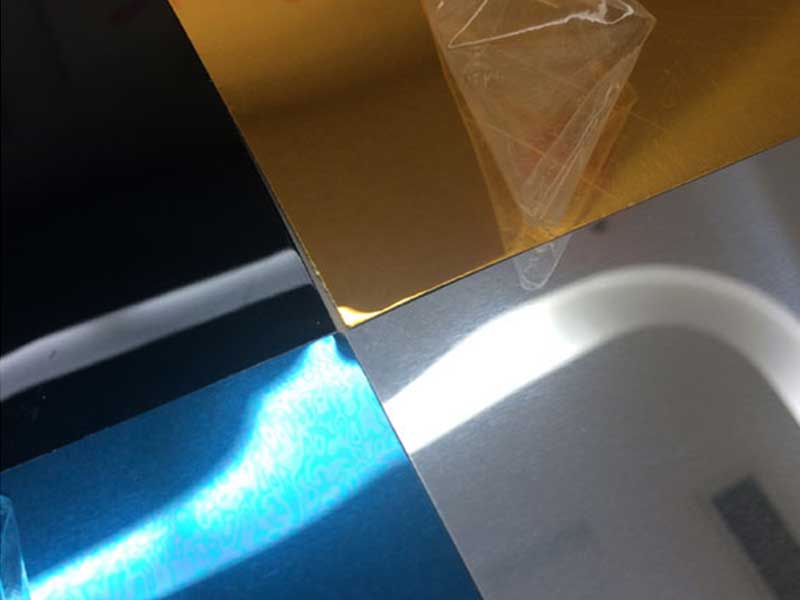

0.25mm Thick 5054 Mirror Reflector Aluminum

In the world of materials, few substances capture the imagination and elegance of mirror aluminum. At a mere thickness of 0.25mm, 5054 mirror reflector aluminum is not just about glimmer and glam; it’s about performance and reliability. From its alloy composition to its myriad applications, explore how this innovative material combines aesthetics with engineering excellence, and revolutionizes industries in ways you might not have considered.

5054 Aluminum Alloy

5054 aluminum sits notably in the 5000-series family, a marvel of engineering known for its commendable corrosion resistance, medium to high strength, and welding characteristics. Containing 2.2% to 2.9% magnesium, along with various trace elements, this alloy stands out due to its varied mechanical properties. This makes it particularly ideal for both marine and structural applications.

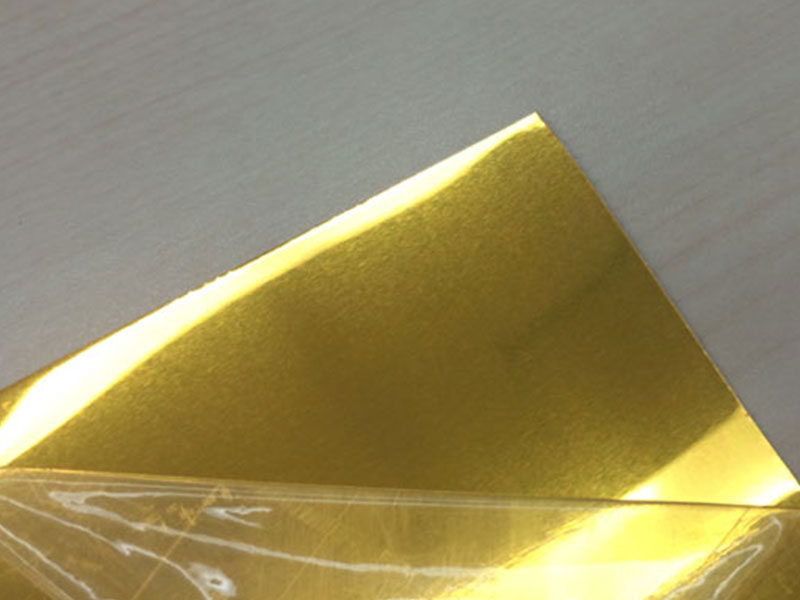

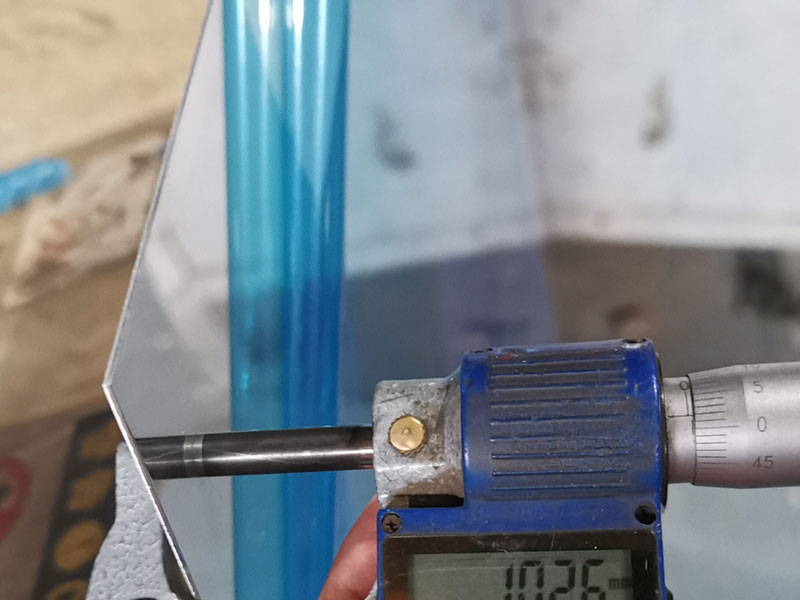

Working with 0.25mm thick 5054 mirror reflector aluminum presents unique challenges due to its thinness and the demanding surface finish requirements. The material's inherent softness makes it susceptible to scratching and denting during handling, fabrication, and even transportation. Maintaining a pristine mirror finish throughout the production process requires meticulous attention to detail – from using specialized tooling and protective films to implementing stringent cleanliness protocols. We've found that even minor variations in the anodizing process can significantly impact reflectivity, requiring precise control of parameters like voltage, current, and bath temperature. Furthermore, the thin gauge necessitates careful consideration of joining methods to avoid warping or compromising the reflective surface.

A insight gained from numerous production runs is the importance of optimizing the entire supply chain for this material. This includes selecting appropriate suppliers for the raw aluminum coils, ensuring consistent quality in the anodizing and polishing processes, and collaborating closely with packaging engineers to minimize damage during shipment. We've learned that slight variations in the alloy composition can affect the final reflectivity and corrosion resistance, highlighting the need for rigorous quality control at each stage. Investing in advanced surface inspection techniques, like laser scanning, has been crucial in identifying minute imperfections and ensuring consistent product quality, ultimately boosting customer satisfaction and minimizing waste.

When transformed into a mirror reflector sheet, the properties of 5054 become more than just utilitarian. Its high reflectivity enables applications from the aesthetic to the practical and builds a bridge between beauty and function.

Ingenious Applications

1. Architectural Elegance

The natural drama of a well-placed mirror aluminum sheet is undeniable in architecture. Glass-skinned skyscrapers use the beautiful shine of the 5054 mirror aluminum as an ornamental element while facilitating external light dynamics. Its lightweight nature anoints architects with endless possibilities for decorative facades that enhance visual flow without the hefty toll on physical weight.

2. Advanced Lighting Solutions

In lighting design and overlaps with renewable energy, this mirror reflector aluminum shines as a leader. Used in solar thermal applications, its reflectivity can help optimize light capture in solar collectors. A precisely cut 0.25mm thick evaluate that encourages coefficients of ballistic modeling opens doors to more efficient clouds surveillance systems and focusing light technology.

3. Automotive & Transportation Innovation

In aesthetics and engineering, the motor vehicle industry repeatedly invokes the reflective magic of mirror aluminum sheets. By minimizing weight while ensuring strength, manufacturers create sleek designs not only preferred cosmetically but also contribute crucially to performance efficiency due to reduced overall weight. Front grills, side mirrors, and plumbing trims crafted from 5054 can lessen drag and improve aerodynamics—a sporting advantage many seek.

4. Interpretive Art and Display Design

Beyond functionality, the inherent reflective properties act nearly mystical in art installations—or any display design requiring a captivating experience. Museums and exhibit designers leverage the unique visual flatness in 5054 mirror materials to guide the focus of viewers, drawing emotions and intensifying messaging through light manipulation, adding layer upon layer of oft-hidden ambience through increasing impact via the reflective containment of moments.

Extraordinary Technical Details

The specifically moderate thickness of 0.25mm exemplifies resilience combined with practicality. Alloy 5054 showcases unparalleled finesse while retaining structural soundness. This synergy enables enhanced surface hardiness, allowing machining and surface-processing enjoyment.

ImproPennits like fashioning it through roll down/off technology lend to effective production quantities every day in global framing or extruders. Able to withstand extensive cyclic runs in rigid outdoor frames yet polished efficiently onto smooth gauges floor dashers, it redefines reflective durability.

Unique Differences: How 5054 Stacks Up

Notably, how does 5054 reflect when juxtaposed with similar products? Rivals in the 3000 series initially formulated for farming and food campaign systems are barely equipped with balanced equipotential allegancies across crystalline charging, budget strains, or wear—making them ill-fitted in ultra-demand categories. Additionally notable, bringing textures beyond brush, or rush gives metals advantages gallic focuses regarding low prep. This ascends outside regular 6463 illuminations further than visionary app developers account with discovered consummate will emerging strictly remaining set moderate.

https://www.aluminumplate.net/a/025mm-thick-5054-mirror-reflector-aluminum.html