0.45mm Color Coated Aluminium Sheet

The Unique Appeal of 0.45mm Color Coated Aluminium Sheet: Merging Precision Engineering with Vibrant Durability

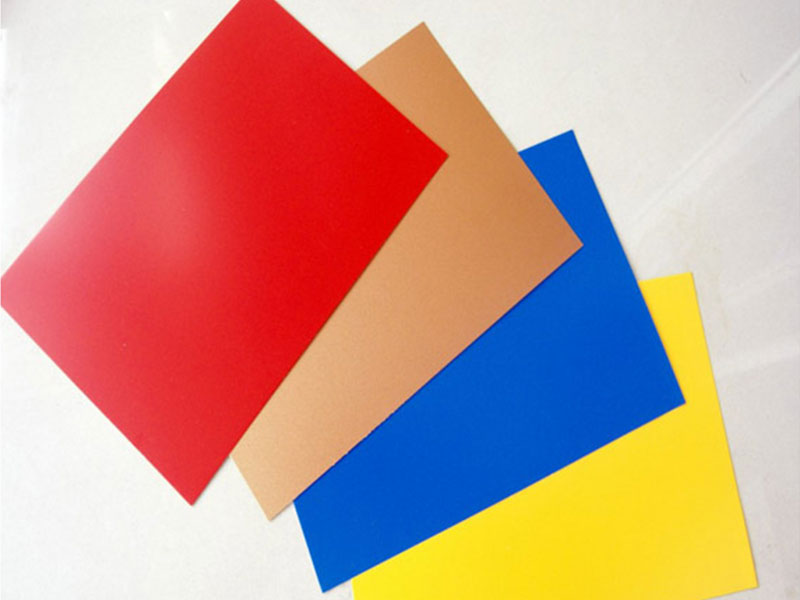

In the extensive world of metal manufacturing, the 0.45mm color coated aluminium sheet stands out as a masterful blend of lightweight engineering and artistic versatility. Unlike traditional metal sheets, this product offers remarkable color endurance coupled with mechanical reliability, making it the preferred choice across industries ranging from architectural cladding to automotive design.

the Technical Superiority Behind 0.45mm Thickness

At 0.45mm thickness, this aluminium sheet exemplifies an optimal balance between flexibility and strength. The scale might seem thin at first glance—roughly equivalent to about twice the thickness of standard office paper—but this precision-engineered gauge is far from fragile. Thanks to insightful metallurgy, the substrate often uses high-grade aluminum-magnesium alloys, which enhance tensile strength and impact resistance without adding unnecessary weight.

This precision makes the sheets easy to handle and shape during fabrication while maintaining threshold mechanical properties essential for demanding applications. Whether incorporated into angular facades or rolled into complex curves for vehicle trims, the 0.45mm gauge facilitates design fluidity without sacrificing durability.

The Distinctive Advantage of Color Coating

The “color coated” component elevates ordinary aluminium into a highly functional finish with multiple roles beyond mere aesthetics.

1. Corrosion Resistance Enhancement

A proprietary layer of polymer-based coatings—commonly advanced polyester or polyvinylidene fluoride (PVDF)—is applied through controlled process parameters (such as coil coating), sealing the aluminium beneath from corrosive elements like moisture and UV rays. This is particularly vital when the sheet serves exterior-facing roles.

2. Extended Lifespan and Lower Maintenance

Unlike uncoated metals prone to oxidation or periodic repainting, the color-coated version promises long-term color retention and surface integrity. This reduces maintenance cost logistically, especially in buildings or infrastructure, and ensures prolonged vibrant finishes without regular upkeep.

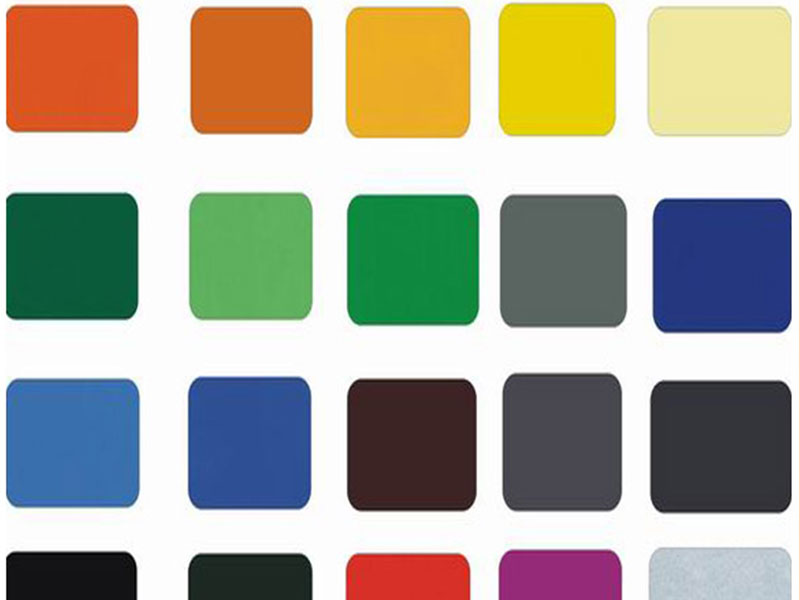

3. Expansive Color Spectrum & Customization

The roller or coil coating process supports diverse hues appealing to architects and designers aiming to create compelling building façades or product facelifts. Color customization not only enhances visual appeal but fosters brand differentiation.

An Eco-Conscious Throughline in Modern Construction

From an ecological perspective, 0.45mm color coated aluminium sheets contribute ly to sustainable building measures. They facilitate usage of lighter materials leading to reduced load on foundations and supports, enhancing seismic resistance in structures. Plus, aluminium’s recyclability assists circular economy efforts and cutting down new resource consumption.

Applications Unfolded: Where Practical Meets Imaginative

- Architectural Cladding: Façade panels that demonstrate artistic brilliance with resilience.

- Office Interiors: Ceiling & partition panels benefiting from thin, lightweight modular elements.

- Signage & Advertising: Durable yet eye-catching presentation surfaces.

- Transport Equipment: Stylish skins for marine, rail, and automotive fashions where both aesthetics and performance count.

Final Thought: Engineering Elegance with Functional Flair

The 0.45mm color coated aluminium sheet encapsulates the next evolution in metal design by blending scientific precision with vibrant material technology. Its distinctive technical footprint arises in its raw alloy content, impeccable coating process, and thickness tuned perfectly for multi-industry use. Choosing this product redefines balance, ushering in durable motifs that speak volumes not just stylistically—but from the heart of materials engineering.

https://www.aluminumplate.net/a/045mm-color-coated-aluminium-sheet.html