Anodized colored Aluminum Sheet 1060 1100 3003 5005 5052

Anodized colored aluminum sheets are rapidly gaining popularity in numerous industries due to their exceptional durability, aesthetic appeal, and versatility. Among the various series available, the 1060, 1100, 3003, 5005, and 5052 aluminum grades stand out for their unique properties and applications.

What is Anodizing?

Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of aluminum products. This layer not only promotes increased resistance to corrosion and scratches but also provides the option for various color finishes. Anodized aluminum sheets offer a more enduring aesthetic than painted options, making them a preferred choice for exterior applications.

Features of Anodized Colored Aluminum Sheets

Enhanced Corrosion Resistance: The anodization process generates a reinforced oxide layer, offering greater resistance to environmental factors. This feature is particularly valuable in areas with high humidity or saline conditions, ensuring the longevity of the material.

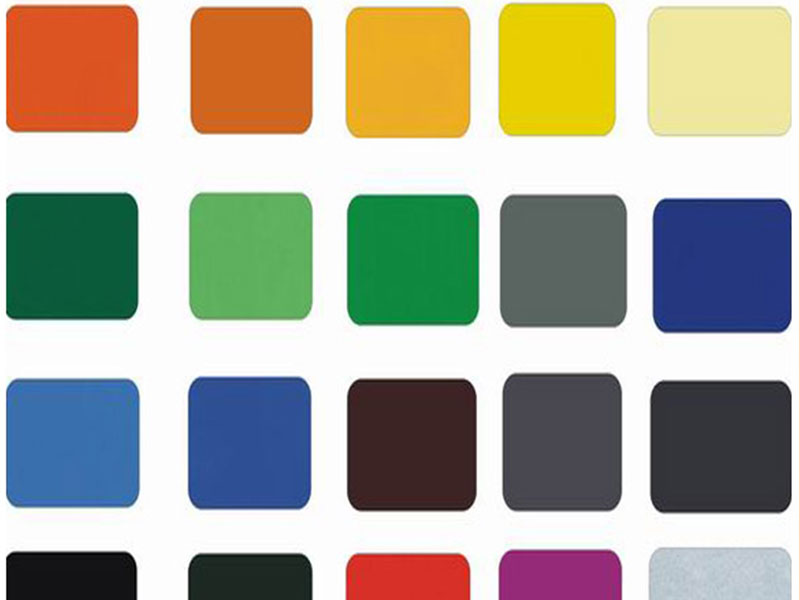

Color Variety: Anodized sheets can be finished in numerous colors, capable of achieving rich metallic looks, vibrant hues, or a matte finish. The deep coloration process produces high-intensity colors complemented by a luminescent reflection.

Durability: Anodized aluminum sheets, including grades 1060, 1100, 3003, 5005, and 5052, have significantly increased hardness, making them ideal for applications requiring both appearance and durability.

Aluminum Grades Explained

1. 1060 Aluminum Sheet

The 1060 aluminum sheet is known for its excellent corrosion resistance and exceptional electrical conductivity. Used often in manufacturing colorful storefronts or ornamental project parts, its high purity allows for precise anodization, perfect for projects where aesthetics are paramount.

2. 1100 Aluminum Sheet

This grade boasts high malleability and excellent workability. Differentiated by its ductility, the 1100 aluminum sheet is ideal for drawing and stamping applications. The anodized finish enhances not only the aesthetic qualities but also the mechanical ability to withstand bending while maintaining color integrity.

3. 3003 Aluminum Sheet

Famous for its moderate strength and excellent corrosive resistance, the 3003 aluminum sheet is often chosen for applications involving chemical surroundings. Its anodization proves sturdiness is coupled beautifully with the versatile shades available while maintaining an extraordinary mechanical properties.

4. 5005 Aluminum Sheet

Widely recognized for its outstanding anodized coloring finishes, the 5005 aluminum sheet fits perfectly in both architectural and decorative applications. Its pigmentation is vibrant and lasting, bringing a sophisticated touch to aesthetics like commercial buildings and panels.

5. 5052 Aluminum Sheet

Leading in terms of resistance to saltwater corrosion, the 5052 aluminum sheet is perfect for extreme environmental conditions. This anodized alloy not only proves well in elemental durability but also tasks that require tight tolerance, contributing much to heavy-duty applications.

Applications of Anodized Colored Aluminum Sheets

Anodized colored aluminum sheets are particularly valued in several sectors, including:

- Architecture: Used for flooring, roofing, and panel systems, delivering a seamless integration of beauty and durability.

- Interior Design: Ideal for creating striking wall coverings and custom surfaces, enhancing aesthetic appeal.

- Transportation: With applications in automotive as well as marine sectors to ensure long-lasting protected finishes.

- Electronics Housing: Popular in cases and casings, anodized finishes offer protection as well as excellent designs.

https://www.aluminumplate.net/a/anodized-colored-aluminum-sheet-1060-1100-3003-5005-5052.html