1060 3003 Color Coated Aluminium Sheet

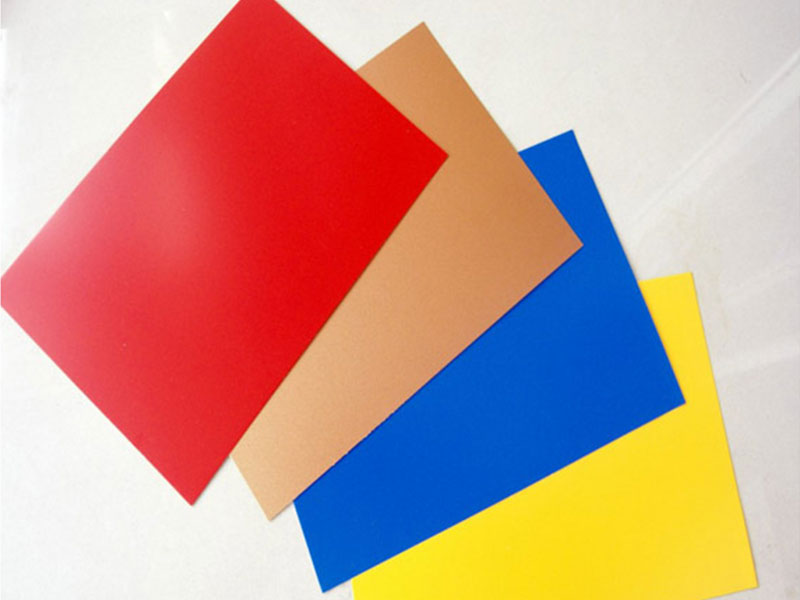

Color coated aluminium sheets, particularly in alloys 1060 and 3003, are widely favored in industries requiring lightweight, durable, and aesthetically appealing metal materials. Whether used in architectural facades, signage, or household appliances, these coated aluminium sheets bring enhanced functionality and versatility.

- The fundamentals and functions of 1060 and 3003 color coated aluminium sheets

- Typical applications

- Comprehensive technical details including parameters, implementation standards, alloy tempering, chemical compositions, and mechanical properties

What are 1060 and 3003 Color Coated Aluminium Sheets?

Both 1060 and 3003 are common Aluminium alloys:

- 1060 Aluminium Sheet: High-purity aluminium (≥99.6%) characterized by excellent electrical and thermal conductivity plus intrinsic corrosion resistance. It is relatively soft and has good workability.

- 3003 Aluminium Sheet: An alloy consisting of about 1% manganese, enhancing strength while maintaining good corrosion resistance and formability.

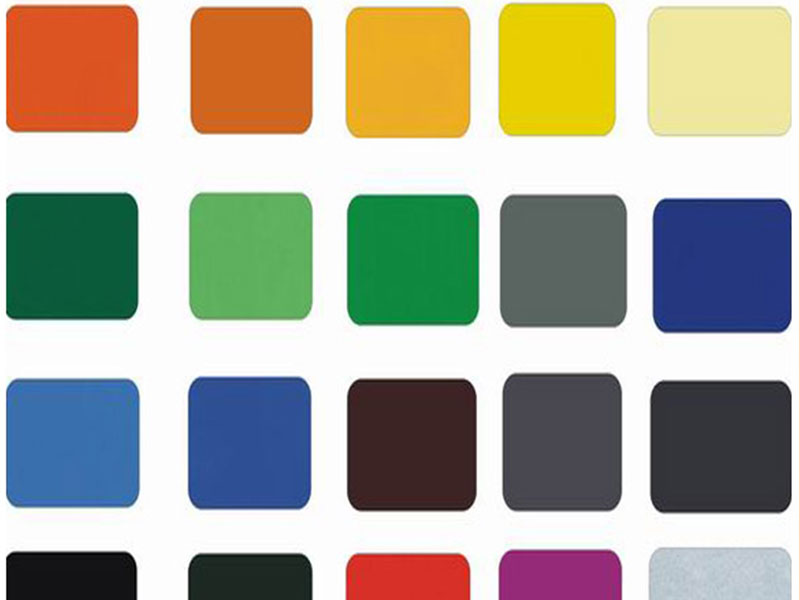

When coated with organic coatings (PVDF, Polyester, Fluorocarbon, etc.), these sheets gain better surface protection, aesthetic value, increased durability, and sometimes additional functionalities like anti-corrosion or anti-UV resistance.

Functions of 1060 & 3003 Color Coated Aluminium Sheet

| Function | Description |

|---|---|

| Corrosion Resistance | Resistant to oxidization especially after coating, suitable for outdoor use |

| Lightweight | Substantially reduces weight compared to steel or other metals, improving ease of handling |

| Superior Aesthetics | Brilliant and long-lasting color finishing, suited for decorative purposes |

| Excellent Formability | Can be easily fabricated into various shapes by bending, cutting, stamping |

| Enhanced Durability | Coating protects the aluminium core against abrasion, weather elements, and UV light |

| Thermal Conductivity | Both alloys possess good thermal properties – useful in ventilation or cladding |

Technical Specifications and Parameters

Chemical Composition

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|

| 1060 | 0.25 max | 0.35 max | 0.05 max | - | 0.03 max | 0.05 max | 0.03 max | Remain (≥99.6%) |

| 3003 | 0.6 max | 0.7 max | 0.05 max | 1.0-1.5 | 0.10 max | 0.05 max | 0.08 max | Remain |

Alloy Temper and Mechanical Properties

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 1060 | H14 | ≥70 | ≥40 | ≥10 | 35~50 |

| 1060 | H24 | 90-110 | 60-80 | 8-10 | 50-70 |

| 3003 | H14 | 100-135 | 55-115 | >6 | 50-80 |

| 3003 | H24 | 160-205 | 95-125 | >6 | 80-100 |

Note: H14 denotes half-hard temper; H24 denotes strain-hardened and partially annealed temper.

Implementation Standards

| Standard | Description | Alloy Coverage |

|---|---|---|

| GB/T3880-2006 | Aluminium and aluminium alloys | Both 1060 & 3003 |

| ASTM B209 | Aluminium plate and sheet standard | Widely referenced internationally |

| JIS H4100 | Aluminium and aluminum alloy sheets | Common in Japan region |

Typical Applications

| Application Area | Details |

|---|---|

| Building & Construction | Exterior wall cladding, façade panels, suspended ceilings |

| HVAC and Ventilation | Air ducts, ventilation hoods and grills |

| Transportation Sector | Interior and exterior finishes on buses, trucks, and trailers |

| Signage & Advertising | Outdoor advertising panels needing long-lived colors and abrasion resistance |

| Household Appliances | Refrigerator housings, decorative appliance panels |

| Electrical Industry | Reflectors, busbars (especially using 1060 alloy for conductivity) |

Surface Treatment and Coating Types

After precise mechanical preparation, Aluminium sheets undergo coating processes such as:

| Coating Type | Characteristics | Common Usage |

|---|---|---|

| PVDF (Polyvinylidene fluoride) | Outstanding colour retention, UV resistance and durability | Architectural cladding |

| Polyester (PE) | Cost-effective, available in many colours | Indoor and outdoor decorations |

| Silicon Modified Polyester (SMP) | Better weather resistance than common PE | Building panels |

| Fluorocarbon Coating | Superior ageing resistance, anti-corrosion | High-end exterior panels |

Thickness of paint layers and cure times relate directly to durability and appearance quality, generally ranging

from 15µm (primer) + 18-25µm (topcoat).

The 1060 and 3003 color coated aluminium sheets merge aluminium’s inherent strengths — light weight, corrosion resistance, electrical and thermal conduction — with the benefits inherent in quality color coating: durability, aesthetics, and weather resistance.

Their chemical structure, mechanical temper options, and conformance to national/international standards make them fit for versatile and enduring applications ranging from construction and decoration to HVAC and transport industries.

Consider these materials when your projects demand an optimal balance between mechanical strength, surface quality, and long-term environmental performance.

Feel free to reach out for more detailed information or customization options to meet specific project needs.

https://www.aluminumplate.net/a/1060-3003-color-coated-aluminium-sheet.html