0.6mm 5052 h12 coated aluminium sheet

0.6mm 5052 H12 Coated Aluminum Sheet: Features and Applications

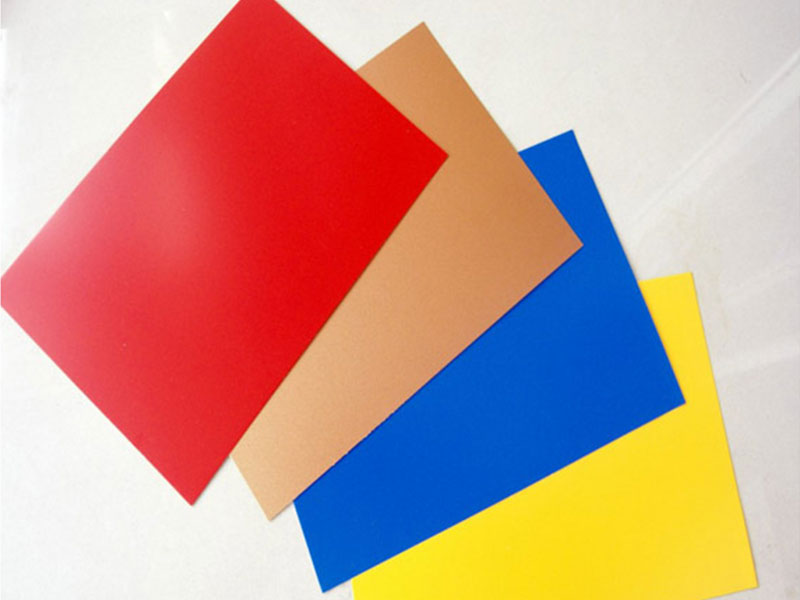

Aluminum has become an essential material across various industries thanks to its lightweight, durability, and versatility. Among the various aluminum alloys, the 5052 alloy stands out for its impressive corrosion resistance and workability. Within the family of 5052 alloys, the 0.6mm 5052 H12 coated aluminum sheet offers exceptional features that cater to a wide range of industrial applications.

Features of 0.6mm 5052 H12 Coated Aluminum Sheet

-

Excellent Corrosion Resistance: One of the defining attributes of the 5052 alloy is its high corrosion resistance, particularly against saltwater and alkaline environments. This makes the 0.6mm 5052 H12 coated aluminum sheet an excellent choice for applications exposed to moisture and industrial chemicals.

-

Formability: The H12 temper of this aluminum sheet reveals its ability to undergo moderate strain without significant deformation. The 0.6mm gauge offers companies flexibility in various fabrication processes, allowing for bending, shaping, and machining while retaining integrity and finish.

-

Good Weldability: 5052 aluminum sheets provide respectable welding characteristics, which makes them particularly valuable in the manufacturing of complex structures, various types of assembly work, and producing gear/components that may require reunification.

-

Lightweight and Strong: Weighing significantly less than steel yet offering comparable strength, the 0.6mm 5052 H12 aluminum sheet is an optimal choice for applications where weight saving is crucial, such as automotive and aerospace industries.

-

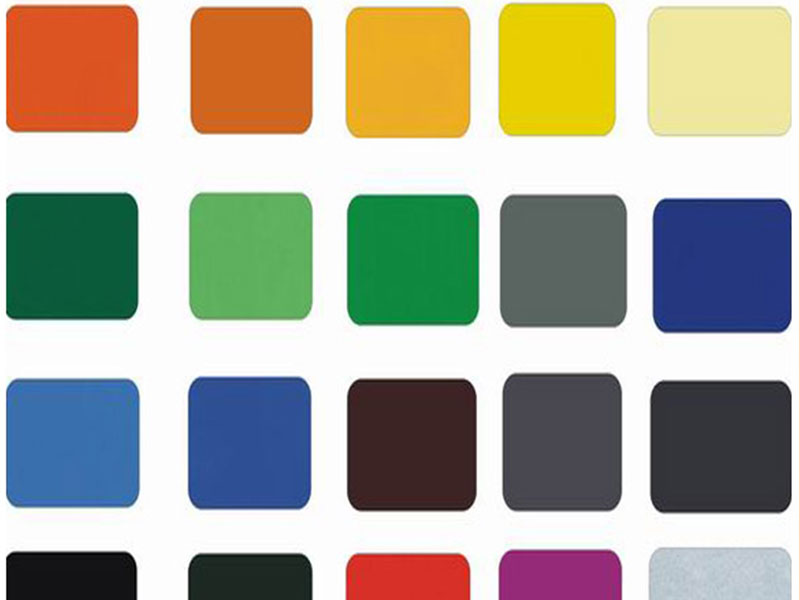

Aesthetic appeal: The coating applied to the aluminum sheet not only enhances its resistance to wear and tear but also improves its visual appeal, making it suitable for applications where appearance matters.

Applications for 0.6mm 5052 H12 Coated Aluminum Sheet

The versatility of the 0.6mm 5052 H12 coated aluminum sheet enables it to serve multiple sectors. Some of the widespread applications include:

-

Automotive Industry: The lightweight nature and corrosion resistance of the 5052 H12 aluminum sheet make it perfect for car manufacturing, including body components and panels that require both strength and formability.

-

Marine Applications: Given its remarkable corrosion resistance against seawater, this type of aluminum sheet is frequently used in boat constructions, floorings for yachts, and other offshore platforms which face harsh saline conditions.

-

Construction and Architecture: Architects and engineers often incorporate coated aluminum sheets into building facades and cladding due to their ability to withstand environmental challenges while offering aesthetic advantages.

-

Refrigeration and HVAC Equipment: With its great strength-to-weight ratio and insulating properties, you will find aluminum sheets crucially employed in the manufacture of heating, ventilation, air conditioning units, and refrigeration cases.

-

Consumer Products: Lightweight, portable products (like toolboxes and decorative items) often rely on the 0.6mm 5052 H12 coated aluminum sheet for its superior finish and high durability.

-

Signage: The robust nature of the coated sheet makes it resistant to fading and weathering, allowing it to thrive in outdoor signage installations while providing long-lasting service with minimal maintenance.

https://www.aluminumplate.net/a/06mm-5052-h12-coated-aluminium-sheet.html