1050 aluminium mirror sheet

Discovering the Unique Functions and Applications of 1050 Aluminium Mirror Sheet

In the realm of materials science and manufacturing, 1050 aluminium mirror sheet stands out not just for its reflective properties, but also for the impactful roles it plays across various applications. As a widely recognized material, it epitomizes balance between functionality and aesthetics, offering unique advantages that go beyond conventional uses. Delving deeper into its properties illuminates why 1050 aluminium mirror sheets are favored across different sectors.

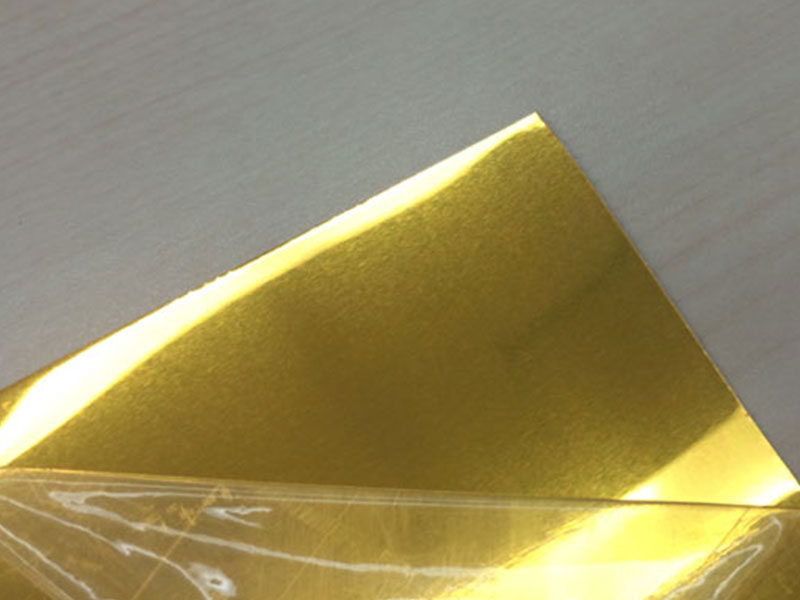

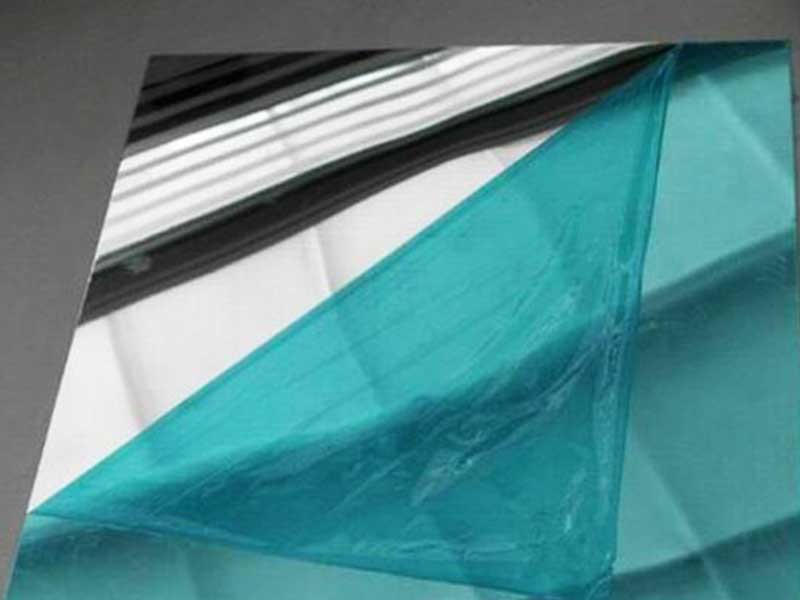

Working with 1050 aluminum mirror sheet daily gives me a unique appreciation for its seemingly simple elegance. It's deceptively challenging to produce a sheet with that level of surface reflectivity. While the 99.5% minimum aluminum content contributes to the brightness, the real magic lies in the precise milling and polishing processes. A microscopic imperfection, a slight variation in pressure during any stage, can drastically impact the final finish. We constantly monitor things like lubricant temperature and the grit of abrasive materials to maintain consistency. A single blemish, barely visible to the naked eye, means the entire sheet might be downgraded, highlighting the precision required for a seemingly simple product.

Beyond the technical aspects, what I find most interesting is the sheer variety of applications. From decorative elements in high-end architecture to crucial components in optical instruments, the 1050 sheet's versatility constantly surprises me. Seeing a design come to life, perfectly reflecting light and embodying the sleekness only a high-quality mirror sheet can achieve, is incredibly rewarding. The fact that something so seemingly basic can contribute to such diverse and often visually stunning projects underscores the importance of consistent quality control and the pride we take in producing a truly exceptional product.

The Reflective Brilliance of 1050 Aluminium

Primarily known for its exceptional reflectivity, 1050 aluminium mirror sheet is a pure aluminium alloy, boasting a minimum of 99.5% aluminium content. This attribute isn’t merely a result of its composition—it stems from careful processing that produces a smooth, shiny surface capable of reflecting up to 90% of light that strikes it. In applications such as lighting fixtures and solar thermal systems, this quality is invaluable.

In lighting applications, the sheet can enhance luminous efficiency by reflecting and distributing light more effectively within a space, leading to reduced energy consumption and improved ambiance. When utilized in solar panels, its reflective nature not only assists in maximizing sunlight capture but also contributes to higher energy yield, highlighting its dual capacity to serve both functionality and sustainability.

Aesthetic Applications in Architecture and Interior Design

Beyond its utilitarian benefits, the visual appeal of the 1050 aluminium mirror sheet is frequently harnessed in the design world. Its sleek, polished finish can impart elegance and sophistication, making it a popular choice in interior decor. Architects and designers often integrate aluminum mirror sheets in feature walls, ceilings, and furniture, creating breath-taking reflections that play tricks with spatial perceptions and light dynamics.

Moreover, the corrosion resistance inherent in aluminium contributes to durability, assuring a timeless beauty that withstands wear and environmental challenges. Extended exposure to air creates a natural oxide layer, which, while initially invisible, serves to protect the underlying material and maintain its mirror finish over time. This longevity conserves aesthetic integrity, making it a wise investment in spaces that demand lasting brilliance.

Versatile Performance in HVAC Systems

Serving functions well beyond the aesthetic, 1050 aluminium mirror sheet is also pragmatic in industrial settings, specifically in heating, ventilation, and air conditioning (HVAC) systems. Utilized in heat exchangers or reflective ducting, its lightweight nature coupled with formidable structural integrity enhances system performance. Reflective duct materials can optimize thermal conditions by minimizing heat loss, significantly boosting overall energy efficiency in climate control.

The lightweight quality also aids ease of installation and reduces energy costs associated with transportation and mechanical operations. These advantages spotlight 1050 aluminium mirror sheets as formidable contenders in industries striving for sustainability.

Innovative Use in Medical Equipment

As medical technology evolves, so does the incorporation of materials like 1050 aluminium mirror sheet in hospital equipment and diagnostic tools. The sheet's properties enable high reflectivity in imaging devices such as MRI machines and dental chairs. By facilitating effective illumination, dimensional reflectivity serves critical functions in clinical diagnostics, leading to enhanced image clarity while contributing to hygienic innovations, as aluminium’s natural properties can deter bacterial growth.

https://www.aluminumplate.net/a/1050-aluminium-mirror-sheet.html