1050 Mirror Finish 0.3mm Aluminum Sheet

When it comes to the realm of aluminum sheets, the 1050 mirror finish 0.3mm aluminum sheet stands out as an exceptional choice, bringing a unique blend of versatility, aesthetic appeal, and practical functionality. Ideal for various applications, this shiny perforated panel is not merely for show; it's a stellar representation of the intersection between art and technology.

the 1050 Mirror Finish Aluminum Sheet

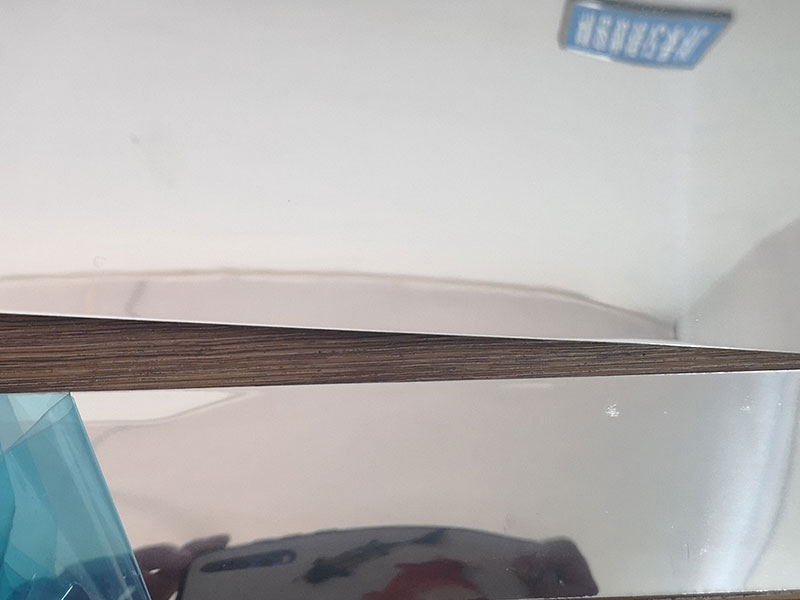

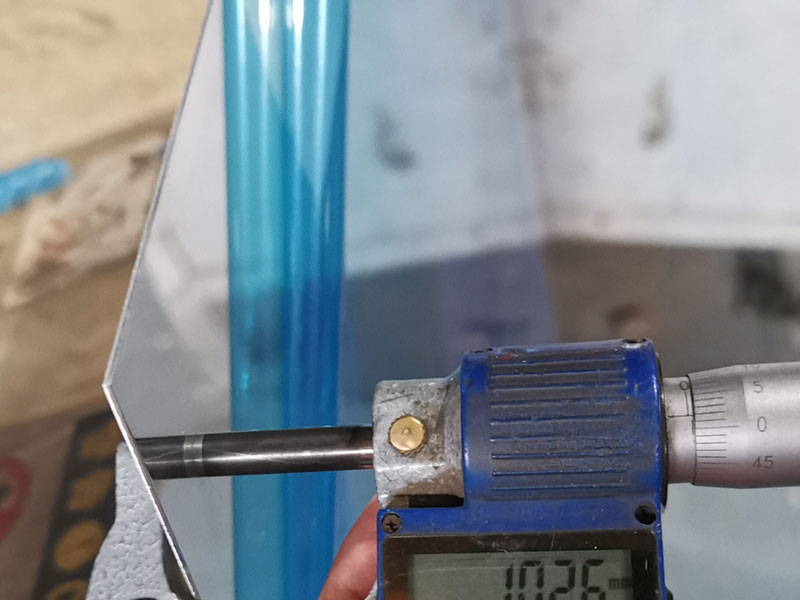

Before diving deeper, it's vital to understand what “1050” is in relation to aluminum metal. The 1050 grade represents aluminum with a purity of 99.5%. This high level of purity contributes to the properties that make it ideal for advanced manufacturing processes. Combined with a mirror finish and a thin, 0.3mm thickness, this aluminum sheet isn't just lightweight; it possesses certain characteristics not easily found in other metals.

Working with 1050 Mirror Finish 0.3mm Aluminum sheet is a constant exercise in precision and patience. Its thinness presents a significant challenge – handling it without scratching or denting requires a delicate touch and specialized equipment. We use specialized rollers and handling gloves, and even the slightest imperfection in our processes can lead to significant waste. The high reflectivity also means we need carefully controlled lighting conditions during inspection to avoid glare and ensure consistent quality. A seemingly minor variation in the polishing process, like a slightly different pressure or speed on the buffing wheel, can dramatically alter the final finish, making achieving that perfect, flawless mirror-like surface a constant pursuit. You learn to appreciate the subtleties of material science on a daily basis.

Beyond the technical aspects, I've found that this specific product holds a unique place in our production line. While other aluminum sheets might find their way into more utilitarian applications, the 1050 mirror finish, especially at this thin gauge, is often destined for more aesthetically driven projects— decorative elements, high-end consumer goods, maybe even artistic installations. Knowing our work contributes to something visually striking is oddly satisfying. It's a reminder that even a seemingly simple piece of aluminum, painstakingly crafted to perfection, can contribute to something beautiful and unique. The pride in achieving that perfect mirror finish, that flawless reflection, is something shared by the entire team involved in its production.

The Science Behind the Mirror Finish

The mirror finish aspect of a 1050 aluminum sheet reflects an advanced processing technique that creates a surface as shiny as a mirror. This is achieved through polishing, chemical anodizing, and careful handling to maintain the pristine integrity of its appearance. The smooth, reflective surface doesn’t merely serve to look good; it plays essential roles in functionality.

Due to minimized light dispersion, areas adorned with a diamondlify reflection feel brighter and more open, allowing architectural designs room for creativity. Moreover, the non-absorbent nature of the surface can contribute to longevity when incorporated into robust exterior applications.

Properties Worth Noticing

-

Corrosion Resistance: One of the biggest advantages of aluminum alloy, particularly of the 1050 series, is its remarkable corrosion resistance. The invisible oxide layer formed on its surface forms a protective barrier, ensuring sustainability even in harsh environments.

-

Malleability: Thin aluminum sheets retain extraordinary malleability. The 0.3mm gauge balances between being lightweight while still providing the structural stability needed for many applications—a remarkable achievement for thin sheets.

-

Aesthetic Flexibility: Whether used as a facade material for buildings, in interior design, lighting formulations, or kitchenware, the visual simplicity and modern appeal roll out creativity across a plethora of fields.

Distinctive Uses: Beyond Conventional Implications

While many appreciate the 1050 mirror finish aluminum sheet for theoretical reasons, it’s versatility in proven real-world applications is what truly illuminates its importance:

-

Interior Design: From high-design furniture pieces to reflective walls in contemporary apartments, each detail using 1050 pure sheets exudes luxury.

-

Signage and Displays: Being a serious contender in eye-catching display solutions, manufacturers often prefer mirror-finish aluminum sheets for signs. The clarity of the surface boosts call-to-action inscriptions and images.

-

Automotive and Aerospace: Lighter components made of 0.3mm aluminum can contribute to better fuel efficiency without sacrificing grade purity.

-

Architectural Features: Incorporating mirror finishes in high-rise structures means designers can engage visually stunning viewpoints that dynamically alters urban canopies, especially given nighttime spectacles an important focus-for both elegance and utility.

The Green Edge

What makes the 1050 mirror finish 0.3mm aluminum sheet more attractive is its eco-friendly aspect. With rising awareness around metal recycling, aluminum, in general, maintains a robust ferment in sustainable development efforts; they can be recycled indefinitely without degrading quality.

https://www.aluminumplate.net/a/1050-mirror-finish-03mm-aluminum-sheet.html