Aluminum coil mirror finish

The world has long been enamored with the reflective beauty of mirrors, and in an innovative twist, the elegance of mirrors extends beyond glass to aluminum, specifically in the remarkable form of aluminum coil mirror finish. This technologically savvy material veers into both aesthetic and functional territories, bending the rules of conventional design with its unbending durability.

Defining the Glossy Allure: Features of Aluminum Coil Mirror Finish

-

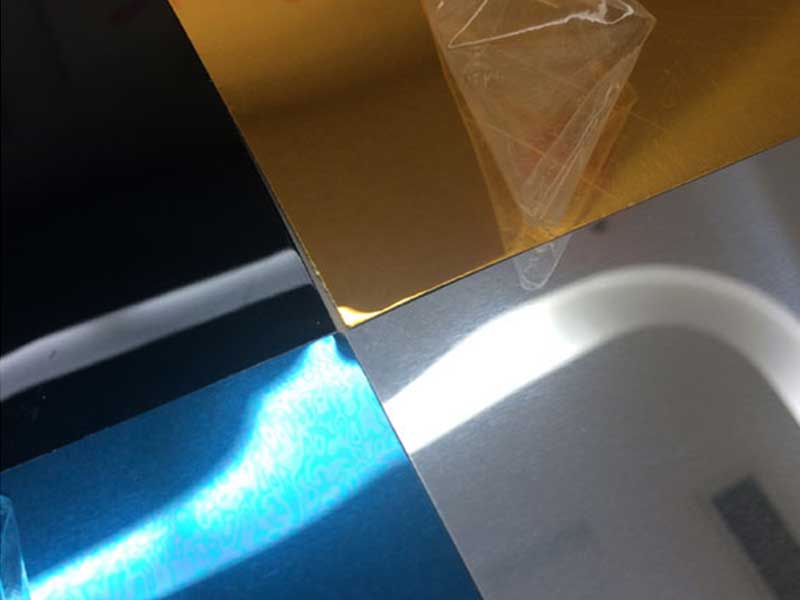

Optical Brilliance: At the heart of aluminum coil mirror finish is its capability to reflect light with unrivaled quality, often boasting a reflectivity of over 80%. This higher level of reflectivity ensures that not only is the surface shiny, but it also creates the illusion of space and light, making it a stylistic choice for diverse interiors.

-

Durable Composition: Unlike glass mirrors, aluminum coil mirrors are lightweight yet resilient. Their unique composition allows them to withstand tough conditions, be it in manufacturing or environmental challenges. Corrosion resistance and impact resistance further solidify their role as the sensible choice where traditional mirrors may falter.

-

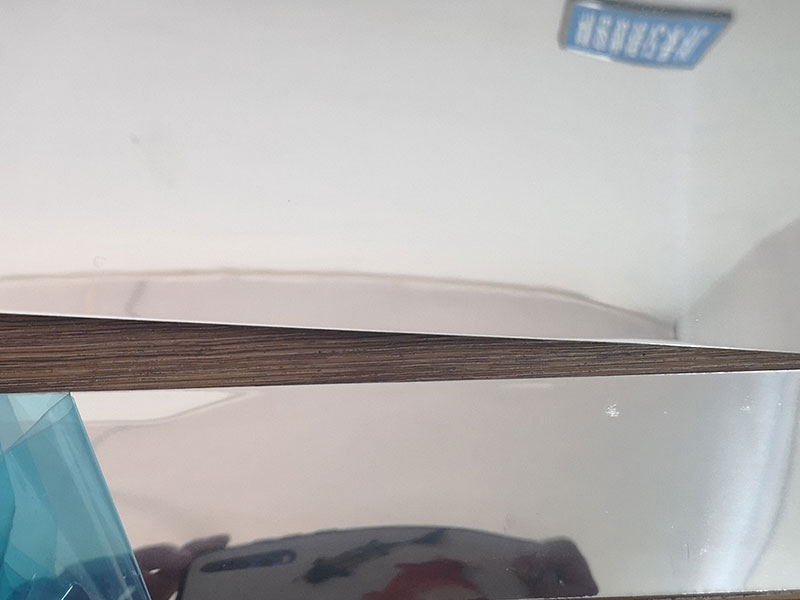

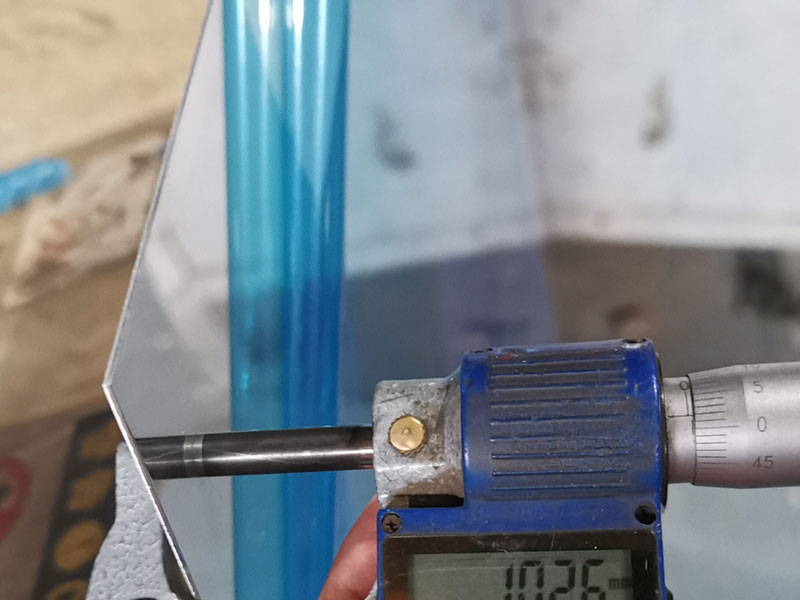

Versatility in Thickness and Size: Aluminum coils can be manufactured to various thicknesses and sizes, allowing aesthetic flexibility. Available in rolls, these afford the user a greater degree of freedom in design while retaining consistency through large runs.

-

Finishing Techniques: The mirror effect is typically achieved through a process called cold rolling, followed by surface treatment and finishing techniques. Different finishing methods ( anodizing, coating, etc.) can enhance the surface complexity, imparting a palette bound only by your imagination.

Applications Woven Across Multiple Sectors

While aluminum coil mirror finishes shine magnificently in every application, numerous sectors capitalize on this compositional brilliance, adapting them according to unique industrial needs:

The mesmerizing gleam of a perfectly finished aluminum coil is a testament to the precision and artistry involved in our manufacturing process. From a technical standpoint, achieving that mirror finish on a continuous coil presents a unique set of challenges. We're not just dealing with the raw material's inherent properties, but also the complex interplay of tension, speed, and temperature during rolling and polishing. Even microscopic imperfections in the base aluminum can be magnified dramatically in the final product, making quality control a critical and often painstaking process. Getting that consistent, flawless reflectivity across hundreds of meters of coil is something I find incredibly satisfying – a tangible result of meticulous attention to detail and constant refinement of our processes.

Beyond the technical aspects, I appreciate the sheer elegance of the material. Seeing a finished coil unwinding, the surface catching and reflecting the light in such a precise way, is always a reminder of the potential hidden within raw aluminum. It's fascinating to consider the diverse applications – from architectural facades that shimmer in the sunlight to high-tech components requiring specific reflective properties – where this seemingly simple material, brought to such a high level of finish, makes a significant impact. The dedication of the entire team, from the mill operators to the quality inspectors, is essential in ensuring our product consistently meets the exacting standards needed for its diverse uses.

Architecture and Interior Design

Elegance marries utility in architecture where mirrors reflect and multiply natural light, sparking radiance in ambiance. This tech-savvy material is sculpted into partition walls, ceilings, and cladding in malls and galleries. It doesn’t merely serve as a design enhancement; it also supports heavy comings and goings without fear of shattered clarity.

Automotive Components

The future of automobile surfaces lies in lightweight materials, and aluminum coil mirrors leap into such trends with ease. Reflective panels are used within automotive aesthetics to calibrate ventilation systems while enhancing their sophisticated appeal both inside and outside vehicle designs. Delving further, mirror technology helps reduce the aesthetics of fogging and distraction thanks to technology-infused coatings.

Goods Packaging

As the quest for consumer engagement thrives, vibrant packaging plays a significant role in influencing purchases. Aluminum coil mirror finishes shelve products with confidence, generating an interactive sheen that draws consumers ahead of their plastic-wrapped competitors. Cosmetic manufacturers often use this allure in eye-catching series, establishing a market presence with unprecedented differentiation.

Lighting Reflection

Aluminum coil iron mirrors redefine outdoor and indoor lighting, dramatically improving light distribution in flooding various spaces ideal for entertainment, landscaping, or usage settings. UIFont combined LED strips with individual designs can manipulate spaces' illusion various scene experiences reminiscent of moods. The functionality metes an approach designed whimsically fashionable.

https://www.aluminumplate.net/a/aluminum-coil-mirror-finish.html