Aluminum tread plate 1060 3003 5083 6061 H24 O

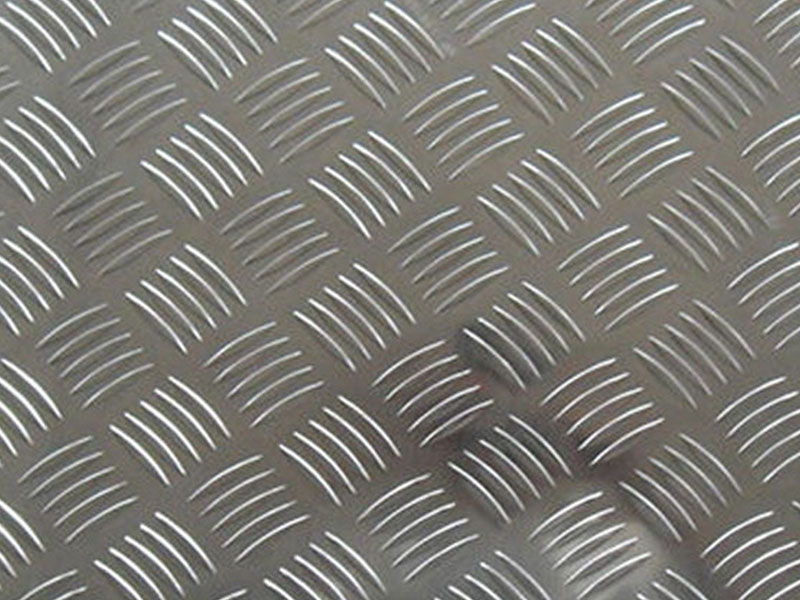

Aluminum tread plates are widely recognized for their unique texture and anti-slip properties, making them a popular choice across various industries—from construction to automotive. Among the different alloys available, 1060, 3003, 5083, and 6061 (especially in H24 and O temper) stand out due to their distinctive features and broad range of applications. Let’s explore each of these aluminum tread plate alloys in detail, highlighting their main characteristics and uses.

1. Aluminum Tread Plate 1060

Features:

- Pure Aluminum: With a purity of 99.6%, 1060 alloy is noted for its high corrosion resistance and excellent thermal and electrical conductivity.

- Lightweight yet Durable: Despite its lightweight nature, it boasts reasonable strength and can resist oxidation well.

- Surface Finish: Often has a decorative pattern, which enhances its visual appeal.

Applications:

1060 aluminum tread plates are commonly used in applications where the aesthetic qualities matter, such as interior design flooring and decorative purposes. Its resistance to corrosion makes it suitable for marine environments, providing a safe grip in wet conditions. It finds ample usage in general sheet metal work and signage as well.

2. Aluminum Tread Plate 3003

Features:

- Manganese Strengthened: This alloy contains approximately 1.0% manganese, which improves its strength and can still be easily worked.

- Corrosion Resistance: Like 1060, it exhibits excellent corrosion resistance but with added toughness.

- Formability: Easily welded and formed, making it a versatile choice for manufacturers.

Applications:

The versatility of 3003 aluminum tread plate allows it to be used in a wide range of industries including food service (for table tops and fixtures), truck tool boxes, and guttering for roofing. It's also commonly used for flooring in industrial applications; its capacity to handle foot traffic while providing slip resistance makes it an ideal choice.

3. Aluminum Tread Plate 5083

Features:

- Magnesium and Manganese Elements: Comprising 4.0% – 5.0% magnesium and 0.4% – 1.0% manganese, 5083 demonstrates notable strength, particularly after welding.

- Exceptional Corrosion Resistance: Especially admired in marine applications due to its resistance against chloride-induced stress corrosion.

- Tough and Durable: Its solid structural integrity allows for utilization under extreme conditions.

Applications:

Aluminum tread plates 5083 are extensively used in the shipbuilding industry, particularly for boat hulls and equipment that must survive harsh marine environments. They are also seen in the manufacturing of high-stress applications like pressure vessels, high-speed ferries, and workboat superstructures.

4. Aluminum Tread Plate 6061 H24 O

Features:

- Alloyed Aluminum: This alloy includes magnesium and silicon, contributing to its strength and making it optimum for high-stress uses.

- Toughness and Workability: 6061 has excellent weldability and machinability, which can be exacerbated by the various tempering processes, such as H24 (which indicates strain-hardened but partially annealed, providing better formability).

- Resistance to Corrosion: Offers lower corrosion resistance compared to some other alloys, but balances this with improved strength.

Applications:

The strength of 6061 H24 O aluminum tread plates makes them ideal for structural applications, including flooring for trucks, trailers, and accessible ramps. In many high-load scenarios, such as assembly plant floor coverings and busy manufacturing settings, its ability to handle substantial weight ensures durability and stability.

https://www.aluminumplate.net/a/aluminum-tread-plate-1060-3003-5083-6061-h24-o.html