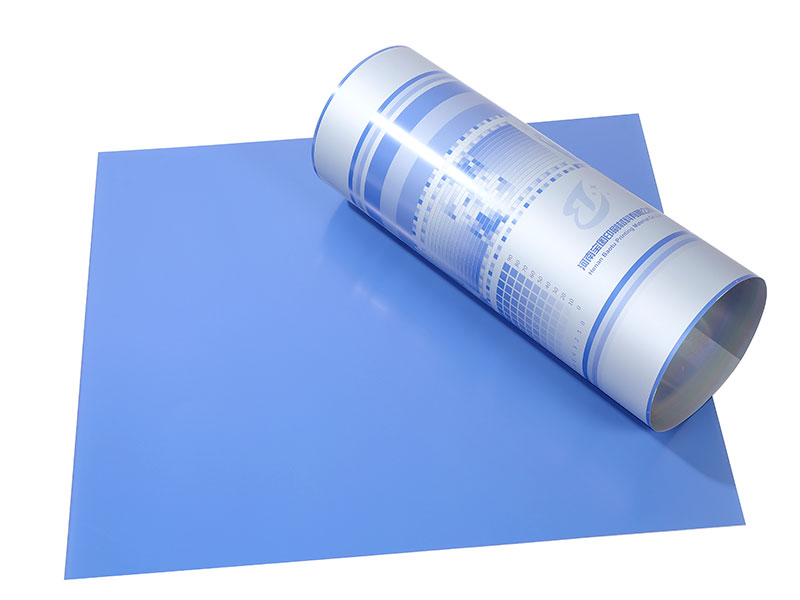

Bridgehead Violet Photopolymer CTP Plate for Offset Printing

Bridgehead Violet Photopolymer CTP Plates have emerged as a breakthrough in the world of offset printing, bringing together innovative chemistry and engineering to deliver superior print quality and durability.

At its core, the Bridgehead Violet CTP plate embodies a sophisticated photopolymer formulation sensitized specifically for violet laser exposure, typically absorbing laser wavelengths near 405 nm. Unlike traditional thermal or continuous tone plates, these violet-sensitive plates emphasize enhanced resolution and swift polymerization, contributing to outstanding image fidelity and repeatability in high-volume print runs.

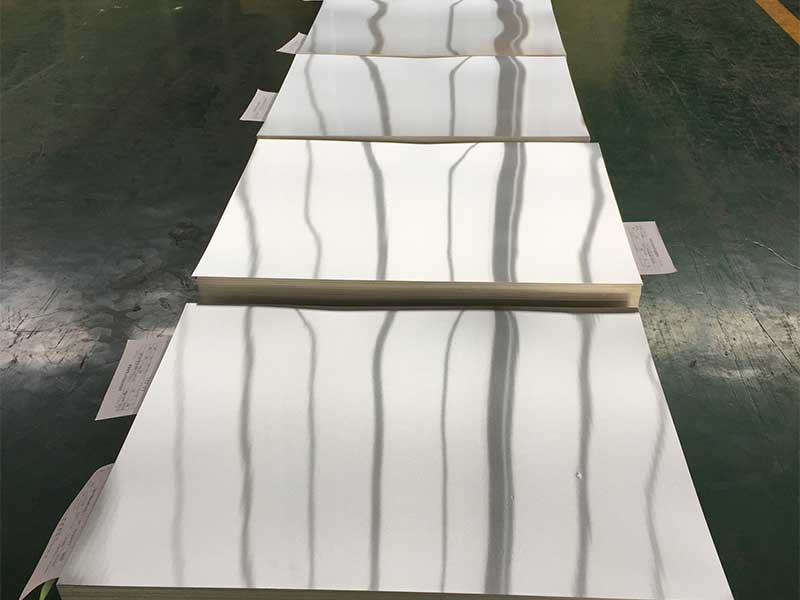

The photopolymer layer works by undergoing a controlled photochemical reaction during violet laser exposure, polymerizing the image-bearing areas while the non-exposed portions remain soluble. Post exposure, a chemical developer removes the soluble segments, leaving raised printing reliefs on the aluminium substrate essential for offset presses.

Technical Specifications

| Parameter | Specification |

|---|---|

| Plate Type | Violet Photopolymer CTP Plate |

| Laser Sensitivity | Near 405 nm (violet laser pointer/diode laser) |

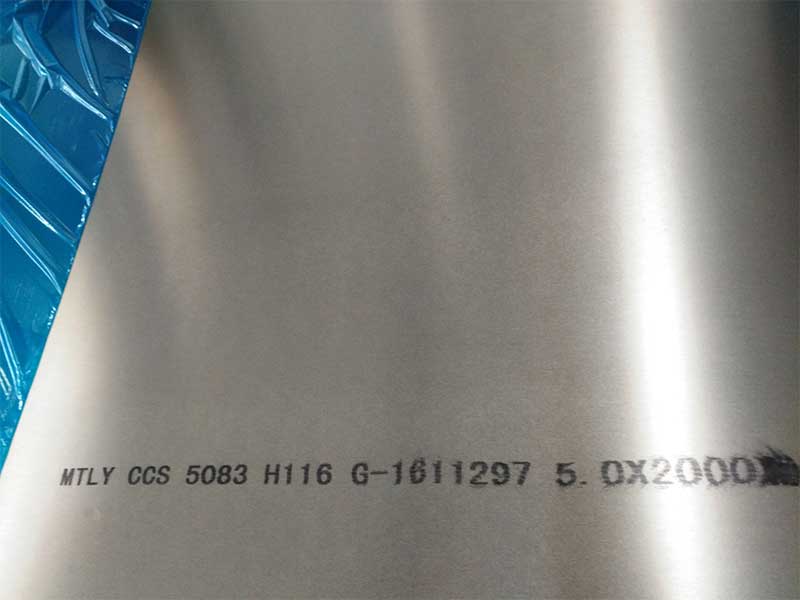

| Base Material | Pure Aluminum (Alloy temper: AA1050/O condition) |

| Plate Thickness | 0.3 mm ± 0.02 mm |

| Resolution Capability | Up to 2400 dpi |

| Processing: | Chemical or solvent-based processor compatible |

| Run Length (Printability) | Up to 250,000 impressions (varies by press and usage) |

| Exposure Time | 90 - 120 seconds (variable depending on laser output power) |

| Storage Conditions | Store in cool (15–25°C), dark, and dry environment |

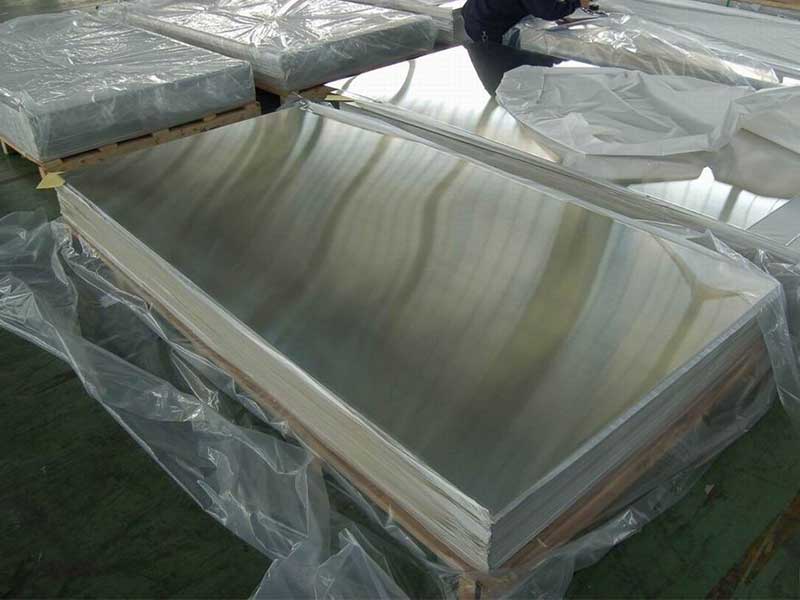

Alloy Tempering and Substrate Advantages

The substrate for the Bridgehead Violet CTP Plate is precision-engineered using AA1050 aluminum alloy commonly tempered in an "O" (annealed) state to achieve flexibility and surface smoothness needed for photopolymer layering. The annealing process, done at ~350°C followed by slow cooling, eliminates internal stresses but preserves tensile strength, yielding an ideal weight of about 2.7 g/cm³ density. This marital ensures plate flatness, resistance to mechanical deformation during mounting, and a robust base not prone to embossing during the blanket-off-contact stage of printing.

Additionally, aluminium’s natural oxide layer and precise graining treat the plate’s surface to augment logical adhesion of the violet-sensitive photopolymer coating, enhancing overall longevity and run-length consistency.

Chemical Profile and Photopolymer Layer Composition

The chemical characteristics of Bridgehead Violet Photopolymer Plates distinguish their photoreactivity and processing sensitivity:

| Component | Chemical Role | Typical Concentration (% wt) |

|---|---|---|

| Acrylate Monomers | Polymer matrix precursors | 65-75 |

| Photoinitiators (Sensitizers) | Activated by 405 nm to start polymerization | 4-8 |

| Crosslinking Agents | Boost mechanical strength post imaging | 8-12 |

| Stabilizers/ Inhibitors | Prolong plate shelf-life and user safety | 1-3 |

| Binder Polymers | Film-forming and adhesion | 10-15 |

| Additives and Flow Control | Enhance coating uniformity, drying rate | <2 |

This proprietary chemistry balances rapid violet laser sensitivity while maintaining resilience in plate-cleaning or processing baths, frequently involving alkaline developers adjusted around pH 11-12 for selective washing of unexposed polymer.

Real-World Applications and Implementation Scenarios

Bridgehead Violet Photopolymer CTP plates cater predominantly to commercial offset printers looking for:

- High Precision Text and Image Prints: Leveraging up to 2400 dpi accuracy, disseminating fine halftones and linework with exceptional clarity.

- Durable High-volume Runs: Capable of withstanding up to 250,000 impressions with minimal degradation.

- Eco-Friendly Processing Compatibility: Most violet photopolymers integrate well with conventional chemical and alcohol-less plate dressings, optimizing ecological impact.

- Economical Plate Lifecycle: Reducing total cost of ownership via lower energy exposure, extended plate longevity coupled with simplified prepress operations.

Industries such as publishing, packaging especially for high-definition graphical artwork, label printing, and even specialized security printing benefit uniquely from Bridgehead’s blend of technological precision and robustness.

What sets Bridgehead Violet Photopolymer CTP plates apart is their chemically tuned sensitivity tailored for violet-laser CTP systems, combined with rugged aluminium substrates treated for optimal polymer adherence and stress-handling proxy conditions guaranteed by AA1050 al foil temper O standards. Print houses integrating these plates often report superior newspaper image sharpness, vial tab enhancements in luxury packaging prints, and greater operational throughput from press downtime dips.

For optimum implementation:

- Carefully monitor exposure rates on your current violet laser output; variance directly impacts polymer cure.

- Use developer solutions as per Bridgehead’s recommendations to avoid under or over-processing.

- Ensure environmental storage avoids humidity extremes which can physically degrade photopolymer film brittleness and sensitivity.

- Work closely within print parameters; substrate alloy temper smoothness is non-negotiable for tension balancing microscales high-density imaging.

Diving deep into the chemistry, metallurgy, and optical physics that_cornerstone these plates demystifies why advanced violet photopolymer CTP plates excel in today’s exacting offset printing ecosystem. Equip your print workflow with Bridgehead Violet plates—not just as a run-of-the-mill material, but a precision-engineered interface where technology meets art.

Harness the future of offset printing via scientific accuracy combined with industrial practicality by choosing Bridgehead Violet Photopolymer CTP Plates—a technical masterpiece for modern print excellence.

https://www.aluminumplate.net/a/bridgehead-violet-photopolymer-ctp-plate-for-offset-printing.html